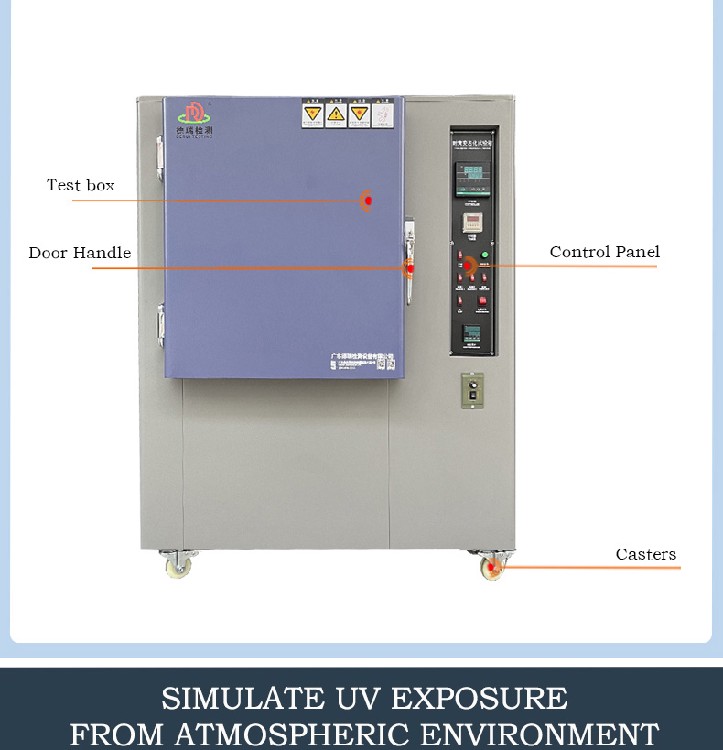

Cosmetics test yellowing-resistant aging test chamber

Product description

The anti yellowing and aging test box for cosmetics is a device specifically designed to test and evaluate the ability of cosmetics and their packaging materials to resist yellowing (yellowing) and aging under long-term exposure to environmental factors such as light, heat, and humidity. It is manufactured strictly in accordance with relevant international standards to ensure the validity and comparability of test results. This type of test chamber is widely used in the cosmetics industry to help manufacturers understand the stability and weather resistance of their products under actual usage conditions, thereby optimizing formulation and packaging design.

main features

Intelligent control system: Adopting advanced computer or PLC control system, it can automatically adjust parameters such as temperature, humidity, and light intensity to ensure consistency and repeatability of testing conditions.

Multi light source selection: Equipped with multiple types of light sources (such as UV lamps, xenon lamps, fluorescent lamps, etc.) to simulate different solar radiation spectra, suitable for the aging testing needs of different cosmetics.

Accurate temperature and humidity control: Equipped with high-precision temperature and humidity sensors and control devices, it can set and maintain stable environmental conditions over a wide range.

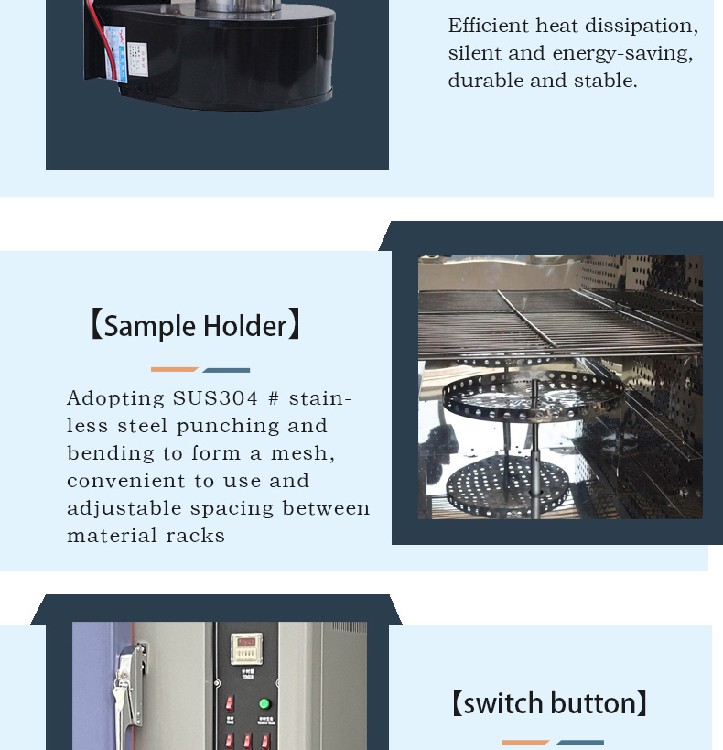

Long term continuous operation: designed for long-term uninterrupted work, with good stability and durability, suitable for long-term aging experiments.

Safety protection measures: including over temperature protection, leakage protection, emergency stop button and other functions to ensure the safety of operators.

Data recording and analysis: The integrated data acquisition system can record various parameters in real-time during the testing process, and perform data analysis and report generation through software.

Functions and Applications

Accelerated aging test: By enhancing environmental conditions to accelerate the aging process of cosmetics and their packaging materials, information about product stability and lifespan can be quickly obtained.

Color change monitoring: Built in colorimeter or other optical measurement tools are used to monitor the color change of the sample, especially the degree of yellowing.

Compliant with international standards: According to ISO, ASTM, DIN and other relevant international standards are used for manufacturing to ensure the validity and comparability of test results.

Diversified testing modes: In addition to basic anti yellowing tests, other types of aging tests can also be conducted, such as wet heat cycling, light stability, etc., by simply replacing the corresponding modules or settings.

Scope of application

The anti yellowing and aging test box for cosmetics is suitable for the following fields:

Cosmetics industry: Evaluate the ability of various cosmetics (such as skincare products, makeup, etc.) to maintain performance over long-term use.

Packaging material testing: Testing the fading and damage of cosmetic packaging materials (such as bottles, lids, labels, etc.) under light and climate conditions.

New product development: Support the development of new products and formula optimization to ensure that the product maintains its quality under various environmental conditions.

Quality control: As part of quality control, ensure the stability and reliability of products on the market.

Selection precautions

When choosing a cosmetic anti yellowing and aging test kit, the following aspects should be considered:

Clear testing requirements: Determine key parameters such as light source type, temperature range, humidity level, etc. based on specific testing purposes.

Accuracy requirements: Clearly define the required measurement accuracy, especially for high-end research or strict quality inspection scenarios.

Additional functional requirements: such as the need for additional testing modules (such as light stability, wet heat cycling, etc.), or non-contact optical measurement equipment.

Space and budget constraints: Reasonably plan the layout of laboratory space and make the best choice based on budget.

Brand and after-sales service: Prioritize selecting brand suppliers who provide excellent technical support and service networks to ensure timely assistance in case of problems encountered during long-term use.

In summary, the anti yellowing and aging test chamber for cosmetics plays an important role in the cosmetics industry with its precise environmental control capabilities and diverse testing functions, providing solid technical support for product quality and reliability.

Recommended products