Multi-Functional Dust Test Chamber for IP5X/IP6X Protection Testing

Product description

Dust Test Chamber Parameter

| Item | Specification |

| Internal dimension | 800W*800D*800Hmm |

| External dimension | 1300W*1000D*1700Hmm |

| Test sample | Size W20cm- L30cm-D15cm, weight 0.5kg |

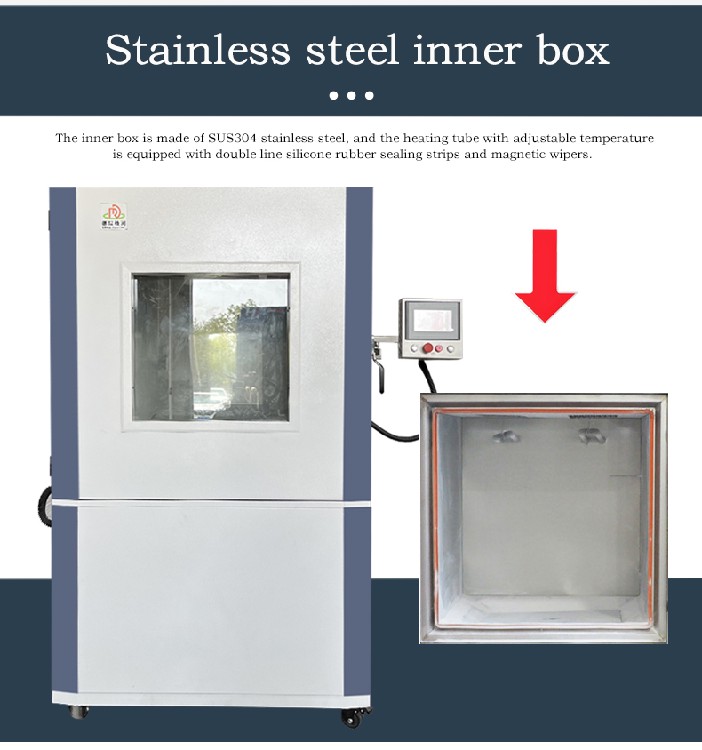

| Chamber material | SUS304 Stainless steel |

| Specifications of square mesh sieve | Mesh hole 75um, mesh metal wire diameter 50um |

| Talcum powder amount | 2kg/ m³ |

| Airflow speed | No more than 2m/s |

| Door | Left open door with tempered glass door |

| Controller | PLC Touch Screen controller, programmable to set as below cycle:a. Blowing dust time (Stop/Blow) m/sb. Cycle time: can be adjustedc. Pre-set test time: 0s ~99m99s |

| Vacuum system | Pressure gauge, air filter, Pressure regulating FRL, connecting pipe, Vacuum pump |

| Vacuum pump capacity | 60-600 L/H |

| Fan | Centrifugal fan |

| Safety protection devices | Meter over-temperature function, Phase shortage protection, Power short-circuit protection |

Multi-functional dust test chamber is an advanced test equipment with a variety of features and functions, suitable for a variety of industries and application scenarios. The following is a detailed description of its main features and functions:

Features

Material and structure:

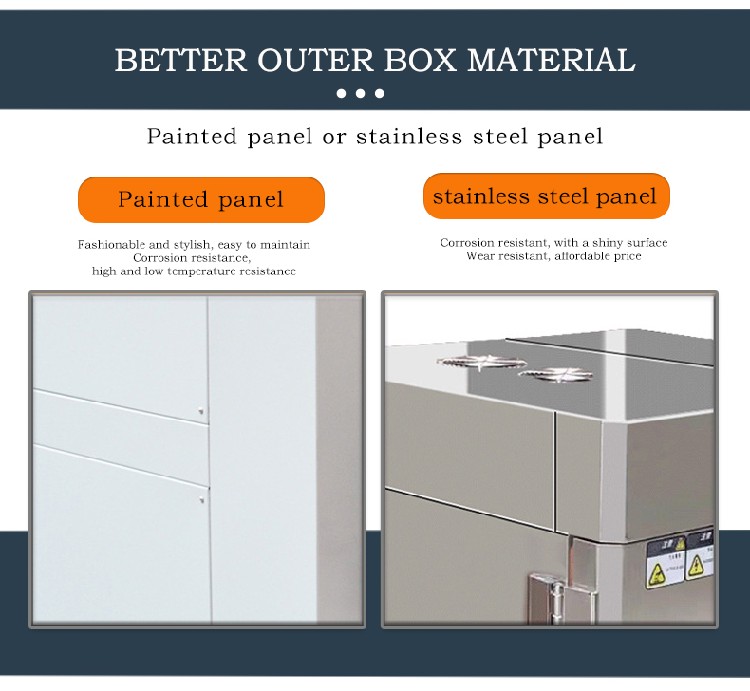

Shell material: usually made of high-quality steel plate with plastic spraying treatment, which has good corrosion resistance and aesthetics.

Inner liner material: mostly imported high-grade stainless steel plate, which ensures the cleanliness and durability of the interior.

Insulation material: adopts rigid polyurethane foam and other materials to effectively keep the temperature inside the box stable.

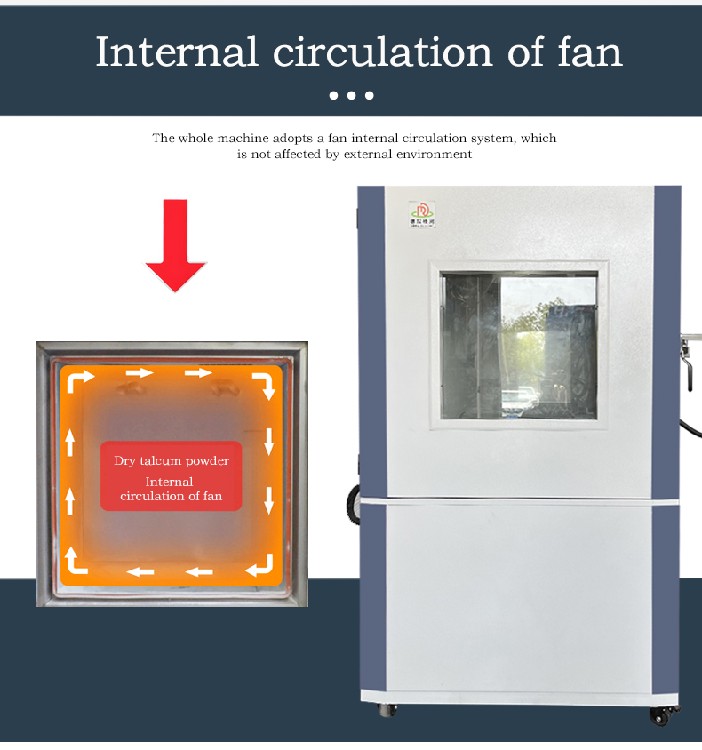

Air duct and fan system: equipped with high-efficiency fans and reasonable air duct design to ensure even distribution of airflow and simulate the real sand and dust environment.

Functional design:

Dust circulation system: through the dust storage box, conveying pipeline and distributor, it is able to evenly distribute the sand and dust to the test area to ensure the uniformity and authenticity of the test.

Temperature and humidity control system: with heating and humidity adjustment functions, it is able to simulate the sand and dust environment under different climatic conditions, making the test more targeted.

Observation and illumination: the door of the box is equipped with a large visual glass observation window with a dust scraper, and the interior is equipped with an explosion-proof and moisture-proof incandescent lamp, which is convenient for observing the condition of the test specimen inside the box.

Control and monitoring system: intelligent digital display controller or microcomputer programmable logic controller, easy to operate, can accurately control the test parameters and real-time monitoring of test data.

Function

Environment simulation:

Able to simulate the sandy and dusty weather in nature, including high temperature, dryness, wind and sand and other extreme climatic conditions, to provide a real and reliable basis for the performance test of the product in harsh environments.

Test Diversity:

Various test items such as dustproof test (e.g. IP5X and IP6X rating test), dust resistance test, etc. can be carried out to evaluate the sealing performance, dust resistance, as well as the reliability and durability of the product in a long-term sandy and dusty environment.

Parameters are adjustable:

Parameters such as wind speed, temperature, humidity, sand and dust concentration can be adjusted and set according to the test requirements to meet the test requirements of different products and standards.

Wide range of application:

Widely used in automotive, electronics, electrical equipment, aerospace, construction materials and many other industries to help test and evaluate the adaptability and performance of various products in sand and dust environments.

Application Scenarios

Multifunctional dust test chambers are suitable for a wide range of industries and testing needs, including:

Automotive industry: testing the dustproof performance of automotive parts such as lights, instruments, electrical dust jackets, etc.

Electronic equipment: Evaluate the sealing and dust resistance of electronic products to ensure their normal operation in harsh environments.

Aerospace: Testing the reliability and performance of aerospace equipment in sandy and dusty environments.

Construction Materials: Evaluate the durability and sealing performance of construction materials in sand and dust conditions.

Through its unique design and function, the multi-functional dust test chamber provides an important test means for the evaluation of product performance in sand and dust environment, which helps enterprises to optimize product design and improve product quality and market competitiveness.

Recommended products