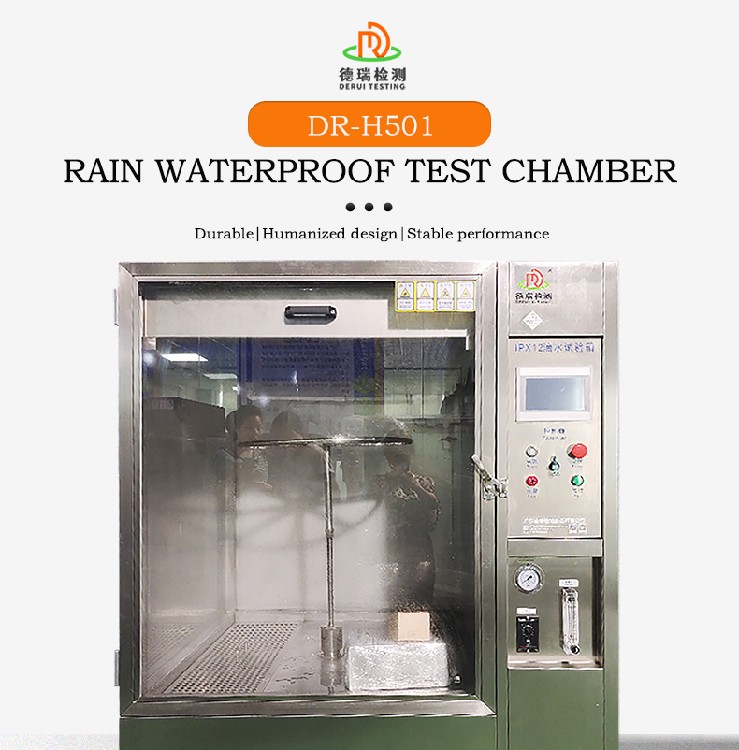

Automotive Waterproof Test Chamber with Programmable Rain Intensity

Product description

Rainfall tester is a test equipment used to simulate natural rainfall environment, mainly used to evaluate the waterproof performance of products under different rainfall conditions. It simulates rainfall of different intensities and angles by precisely controlling the spray angle and water flow of the nozzles, in order to test the waterproof performance of the product and its working efficiency under rainfall conditions. Below are the details of the rainfall tester:

Working Principle

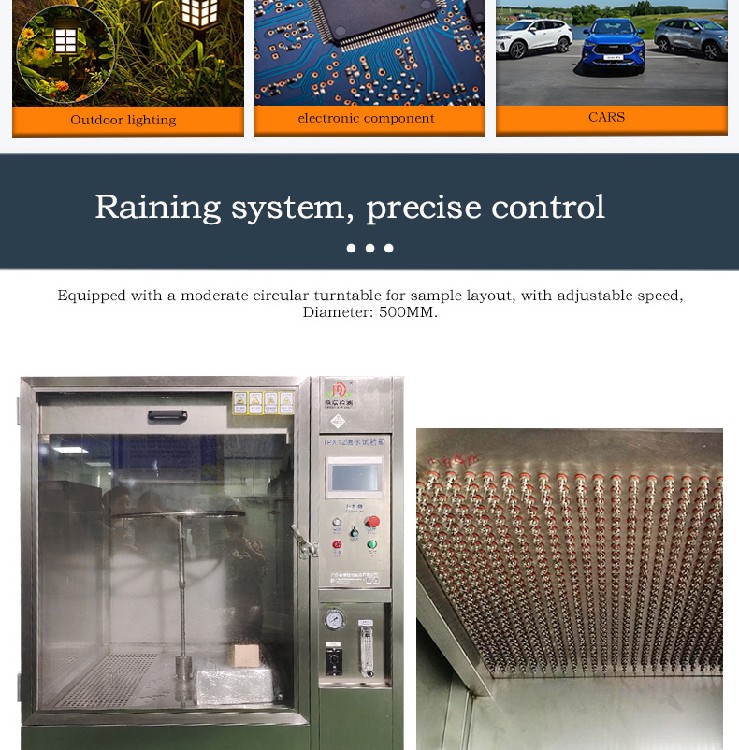

The rainfall test chamber simulates the precipitation phenomenon in nature through the nozzle system. The nozzles inside the chamber can shower the product with rain of different intensities according to the set standards. The temperature and humidity conditions inside the chamber can also be adjusted as needed to better simulate different climatic environments. By controlling parameters such as water pressure, number of nozzles, drip volume and spray angle, the rain shower test chamber can accurately simulate a wide range of environmental conditions from light rain to heavy rain, and from light wetting to large-scale flooding.

Applications

Drenching rain test chamber is widely used in many industries, including:

Electronic products: such as cell phones, tablet PCs, smart watches, etc. By simulating the scene of rain dripping or spraying, the waterproof performance of the products in a wet environment is examined.

Automobiles and accessories: used to test the waterproof performance of automobile lights, window seals and other components, to ensure that when driving in the rain, these components can work properly and avoid rainwater seeping into the car.

Aerospace: To test the waterproof performance and durability of aerospace products and their materials in rainfall environments.

Outdoor equipment: equipment such as outdoor cameras, solar panels, etc., need to undergo a rain test to ensure their waterproof performance and weather resistance.

Operation Steps

Place the test chamber in a well-ventilated place with suitable temperature and humidity.

Turn on the power, open the power switch and make sure the controller enters the fixed value stop interface.

Place the test specimen on the sample rack, note that the capacity of the test specimen should not exceed 2/3 of the capacity of the test area.

Set up the test according to the operation manual, including water flow, nozzle angle, temperature and other parameters.

Start the test according to the set operation mode, observe and record the data during the test.

At the end of the test, turn off the equipment and clean the inside of the test chamber to ensure that the equipment is clean and dry.

Maintenance and Precautions

Regular maintenance: check whether the nozzle is blocked regularly, clean the water and impurities inside the box to ensure the normal operation of the equipment.

Water quality requirements: use pure water or deionized water, to avoid impurities in the water to affect the test results and equipment life.

Safety norms: the operation process should strictly comply with the safety norms, avoid opening the door of the box when the equipment is running, to prevent water splashing out of the hidden safety hazards.

By simulating the complex rain environment, the rain test chamber helps enterprises to effectively assess the waterproof ability and durability of products to ensure their stability and reliability in actual use.

Recommended products