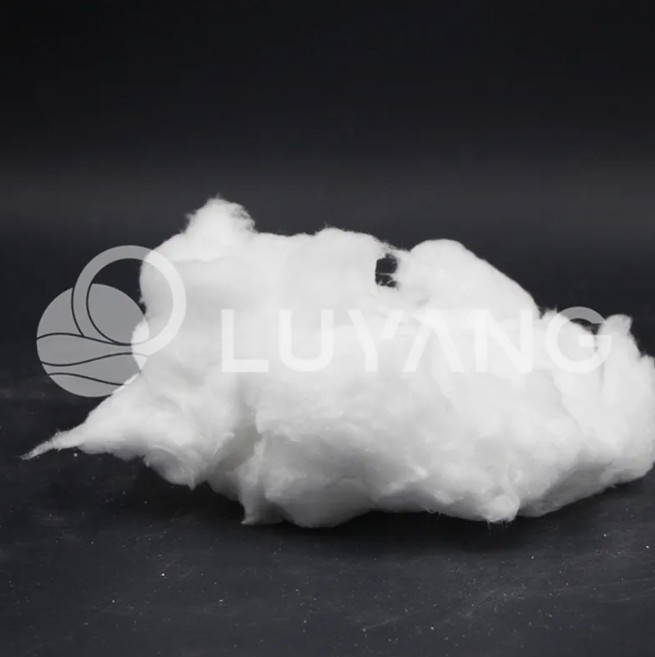

Ceramic fiber fireproof materials delivered directly by the supplier

Product description

Ceramic fiber fireproof materials are high-performance and lightweight insulating materials renowned for their superior thermal resistance, energy efficiency, and adaptability in extreme temperature environments. Primarily composed of alumina-silica compounds, these synthetic fibers are engineered through high-temperature melting and spinning processes, resulting in a flexible yet durable material capable of withstanding temperatures exceeding 1,600°C (2,912°F). Their unique properties make them indispensable in industries where fire safety, thermal management, and operational efficiency are critical.

Characteristics

Exceptional Thermal Resistance: Ceramic fibers exhibit extraordinary heat tolerance, maintaining structural integrity and insulation performance even under prolonged exposure to extreme temperatures. Unlike organic materials, they do not combust, melt, or release harmful gases.

Low Thermal Conductivity: With minimal heat transfer properties, ceramic fibers effectively insulate equipment and structures, reducing energy loss and enhancing operational safety.

Thermal Shock Resistance: These materials resist cracking or degradation when subjected to rapid temperature fluctuations, ensuring long-term reliability in dynamic thermal environments.

Chemical Inertness: Resistant to most acids, alkalis, and corrosive gases, ceramic fibers perform consistently in chemically aggressive settings.

Lightweight and Flexible: Their low density and malleability allow for easy installation in complex geometries without compromising mechanical strength.

Applications

Ceramic fiber fireproof materials are widely employed across industries such as:

Metallurgy: Linings for furnaces, kilns, and molten metal handling systems.

Petrochemical: Insulation for reactors, pipelines, and high-temperature storage units.

Aerospace: Heat shields and fire barriers in engines and spacecraft components.

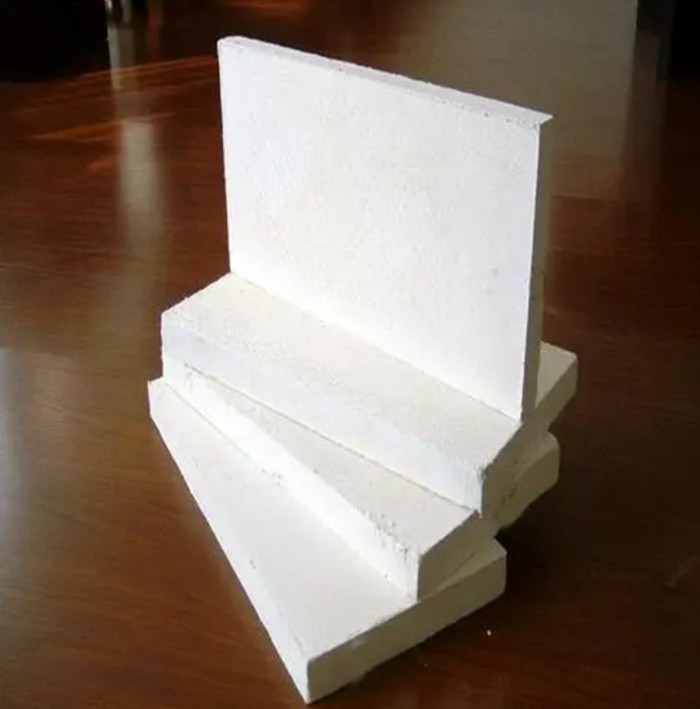

Construction: Fire-resistant panels, fire doors, and insulation for industrial boilers.

Automotive: Exhaust system insulation and fire protection in electric vehicle batteries.

Power Generation: Thermal insulation for turbines, boilers, and nuclear facilities.

Environmental and Economic Benefits

Ceramic fiber materials contribute to energy conservation by minimizing heat loss, thereby lowering fuel consumption and carbon emissions. Their durability reduces maintenance costs and replacement frequency, while their recyclability aligns with circular economy principles. Additionally, their non-toxic composition ensures compliance with global environmental and safety standards.

About Us

Luyang Energy-Saving Materials Co., Ltd. was established in 1984 and was listed on the Shenzhen Stock Exchange in 2006 (stock code: 002088). After more than 30 years of development, Luyang has become a world-renowned research and development, production, and sales enterprise of new energy-saving materials in the fields of ceramic fibers, soluble fibers, alumina fibers, rock wool fibers, and thermal insulation refractory bricks.

Luyang is a professional manufacturer of inorganic fiber materials; Drafting units for international and national standards; A leader in the field of energy-saving and environmentally friendly materials.

The company's products have a high demand nationwide and are sold to more than 60 countries and regions such as the United States, the European Union, Japan, and Vietnam. Luyang's products are widely used in the fields of petrochemical fire-resistant insulation, long-distance pipeline insulation, building fire protection, ship fire protection, home appliance fire protection, and high-temperature insulation.

Recommended products