Fiberglass Mesh: Precision Reinforcement for Next-Generation Building Excellence

Product description

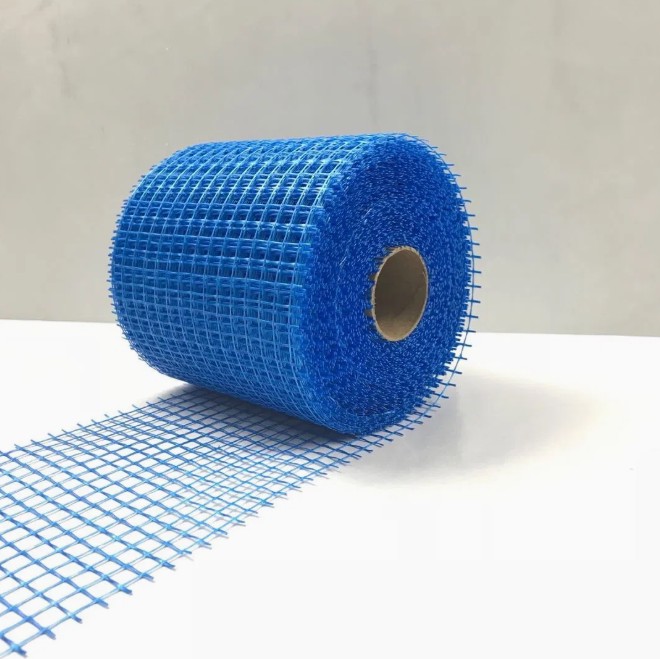

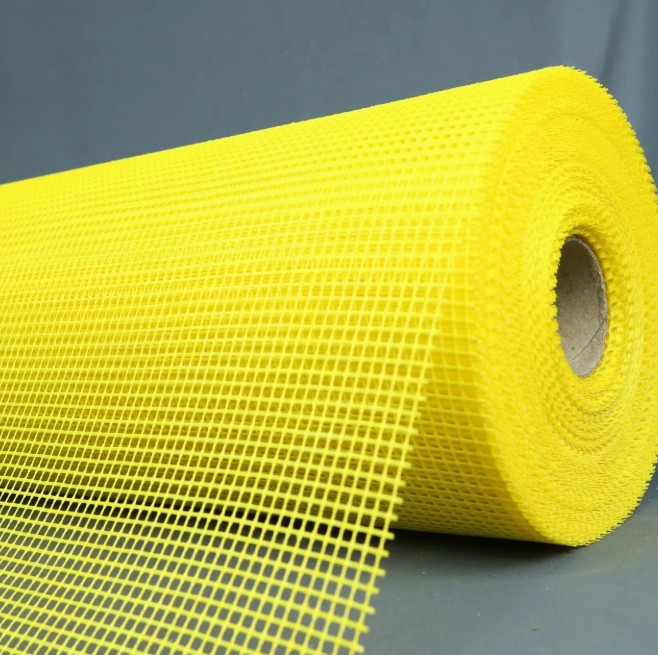

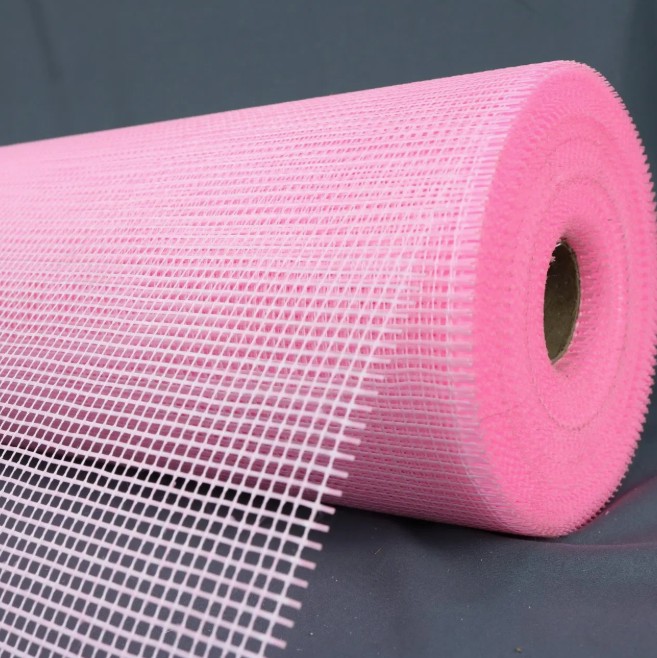

Product Overview

Fiberglass Mesh is an engineered reinforcement solution designed to redefine durability and performance in modern construction and industrial applications. Crafted from high-density, corrosion-resistant glass fibers intricately woven into a uniform grid and fortified with a proprietary alkali-resistant coating, this mesh acts as an invisible shield against structural weaknesses. Its innovative design bridges the gap between flexibility and strength, enabling it to reinforce everything from delicate interior finishes to rugged exterior systems.

Available in customizable specifications, including mesh counts (2x2mm to 8x8mm), roll widths (up to 2m), and specialized coatings (waterproof, UV-stabilized), it adapts seamlessly to projects demanding precision and reliability.

Core Benefits

1. Engineered for Extreme Performance

- Ultra-High Tensile Strength: Withstand up to 3,500 N/cm² tensile force, outperforming traditional metal meshes while eliminating corrosion risks.

- Dynamic Load Resistance: Ideal for structures exposed to vibrations, seismic activity, or heavy machinery, maintaining integrity under continuous stress.

2. Smart Crack Mitigation System

- 3D Stress Distribution: Multi-directional grid design disperses mechanical and thermal stresses, preventing micro-cracks in concrete, plaster, and polymer renders.

- Zero-Shrinkage Guarantee: Compatible with rapid-drying compounds, ensuring adhesion without warping or delamination.

3. Climate-Adaptive Durability

- Arctic to Desert Ready: Operate flawlessly in temperatures ranging from -50°C to 150°C with UV-resistant variants for sun-exposed exteriors.

- Marine-Grade Protection: Chloride-resistant coating option for coastal infrastructure, offshore platforms, and pool linings.

4. Effortless Installation & Cost Efficiency

- Precision-Cut Technology: Laser-guided edges enable seamless overlapping without bulk, reducing material waste by 30% compared to standard meshes.

- Single-Step Application: Embed directly into wet adhesives, mortars, or epoxy resins-no pre-treatment or specialized labor required.

5. Sustainability at Scale

- Carbon-Neutral Production: Manufactured using 40% recycled glass content and low-emission processes.

- End-of-Life Recyclability: Fully reclaimable material supports circular economy goals in green building certifications (LEED, BREEAM).

6. Multi-Industry Versatility

- Construction: Reinforce thin-film renders, terra cotta façades, and insulated sandwich panels.

- Civil Engineering: Stabilize asphalt roadways, bridge expansion joints, and railway embankments.

- Aerospace & Automotive: Lightweight composite core for prototyping and thermal insulation.

Technical Superiority

1. Coating Integrity: Double-layered acrylic with silicone hybrid coating ensures 99% alkali resistance (tested per EN 13496).

2. Fire Compliance: Achieve Euroclass A1 non-combustible rating, which is critical for high-rise and public infrastructure.

3. Quality Assurance: Every batch undergoes 12-point inspection, including mesh symmetry, coating adhesion, and accelerated aging simulations.

Application Innovations

1. 3D-Printed Construction: Embedded mesh layers in 3D-printed concrete for fault-free vertical builds.

2. Green Retrofitting: Core component in external thermal insulation composite systems (ETICS) for energy-efficient building upgrades.

3. Smart Infrastructure: Integrate with IoT-enabled sensors in "self-monitoring" walls to detect stress points preemptively.

Why We Lead the Market?

1. Global Compliance: Meet ASTM E2098, ISO 10456, and GB/T 9914.3 standards for international project compatibility.

2. Tailored Solutions: Offer RFID-tagged rolls for inventory tracking or custom-printed mesh for branding on large-scale sites.

3. Lifetime Technical Support: Dedicated engineering team assists with load calculations, installation robotics, and hybrid system design.

Future-Proof Your Projects

In an era where buildings must endure smarter, greener, and longer, our Fiberglass Mesh isn’t just a product-it’s a pledge of permanence. From skyscrapers to smart cities, we deliver the hidden strength that visible excellence demands.

About Us

Jiangxi Ming Yang Glass Fiber Co., Ltd. is a leading manufacturer specializing in high-quality glass fiber products, established with a commitment to innovation, sustainability, and excellence in the composites industry. Based in Jiangxi, China, the company leverages advanced production technologies and strict quality control systems to deliver a diverse range of fiberglass materials, including yarns, rovings, fabrics, and customized solutions widely used in construction, automotive, electronics, wind energy, and infrastructure sectors. With a focus on R&D and customer-centric collaboration, it serves clients globally while adhering to international standards and environmental responsibility, aiming to drive progress through lightweight, durable, and high-performance composite materials.

Recommended products