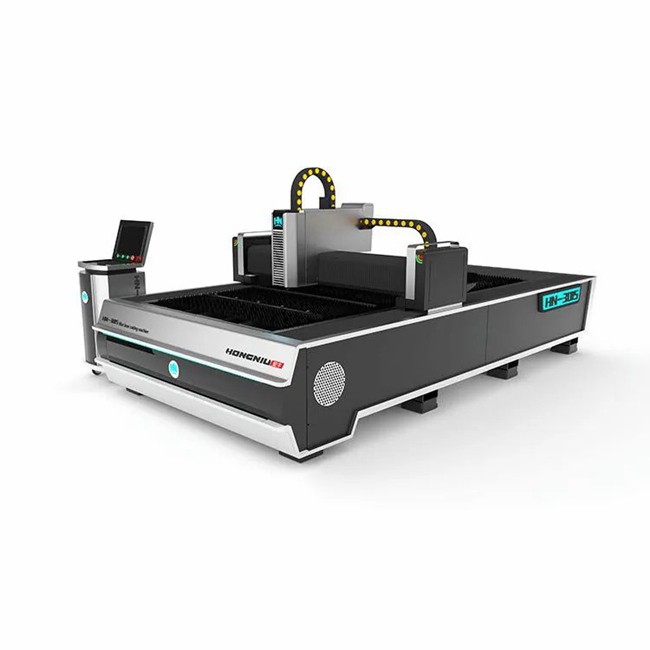

Introduction to the New CO2 Laser Cutting Machine

Product description

CO2 laser cutting machines utilize a gas laser (carbon dioxide mixed with nitrogen and helium) to generate a high-powered infrared beam at 10.6 μm wavelength. This technology excels in processing non-metallic materials and thin metals, making it a versatile solution for industries requiring intricate designs, smooth finishes, and rapid production. The laser beam is directed by mirrors and focused through a lens, vaporizing or melting materials with pinpoint accuracy while minimizing thermal distortion.

Advantages of CO2 Laser Cutting Machines

1. Superior Material Versatility

CO2 lasers outperform fiber lasers for non-metallic materials:

Achieve polished edges on acrylic and wood without post-processing.

Cleanly cut heat-sensitive materials (e.g., fabrics, foams) with minimal burn marks.

Etch or engrave glass, ceramics, and coated metals with high detail.

2. Cost-Effective Operation

Lower initial investment compared to high-power fiber lasers.

Minimal maintenance: Gas refills and mirror/lens cleaning are primary upkeep tasks.

Energy-efficient operation for small to medium-scale production.

3. High-Quality Finishes

Smooth and sealed edges on plastics (e.g., PMMA, polycarbonate), eliminating secondary polishing.

No mechanical contact ensures scratch-free surfaces on delicate materials.

4. Speed and Precision

Cut speeds up to 30m/min for thin materials (1–5mm thickness).

Ideal for complex geometries, micro-perforations, and fine text engraving.

5. Environmentally Friendly

Reduced material waste due to AI-powered nesting software.

Compatible with filtration systems to safely manage fumes from plastics and woods.

6. Industry-Specific Applications

Signage & Advertising: Precision-cut acrylic displays and LED-lit letters.

Textiles: Intricate patterns on leather, denim, and synthetic fabrics.

Packaging: Prototype molds and cut custom plastic/paperboard designs.

Automotive: Gaskets, interior trim, and dashboard components.

Medical: Sterilizable plastic parts and lab equipment.

Why Choose CO2 Laser Technology?

CO2 laser cutters remain unmatched for organic and composite materials, offering:

Adaptability: Easily switch between cutting, engraving, and marking tasks.

Scalability: From desktop models for startups to industrial systems for mass production.

Longevity: CO2 laser tubes last 10,000+ hours with proper maintenance.

Technical Edge:

Dynamic Focus Control: Maintain beam consistency on uneven surfaces.

Auto-Calibration: Ensure accuracy across large-format work areas (up to 1600x3000mm).

Smart Cooling Systems: Air or water cooling options for stable long-term operation.

Why choose us?

About HongNiu Laser: Since 2012, the premium OEM factory has been offering a 3-year warranty. The manufacturer assesses independent third-party R&D capabilities for customization, high-performance manufacturing capacities, and professional certifications and approvals.

1. Technical R&D:Environmental Advantage : Dust-free Quiet Environmental Friendly.

2. Customer Service Advantage:7*24H fast response service.

3. Free Training:free complete standarized training on machine operation to HongNiu traning center.

4.Timely delivery. Each machine is arranged with assembly precise steps without any delay.

5.After-sales services and Guarantee. We offer 2 years warranty. If any problem happens during the period, we are responsible to solve. And if any part of the machine is broken, this situation rarely occurs.

6.Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

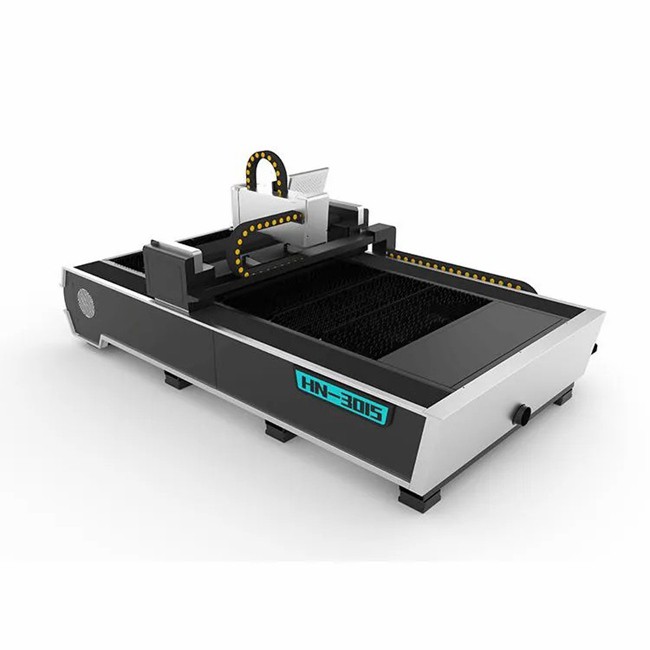

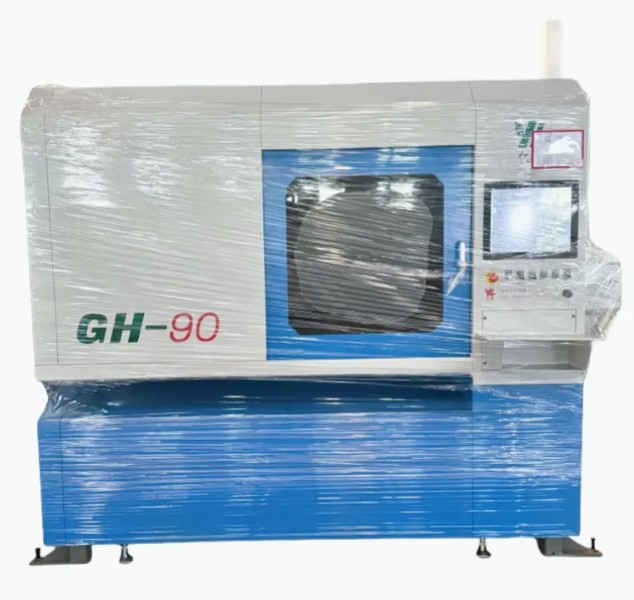

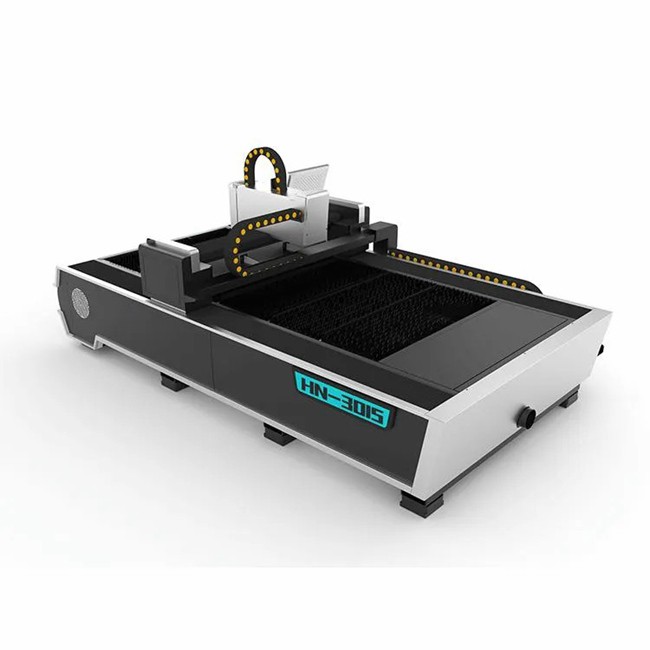

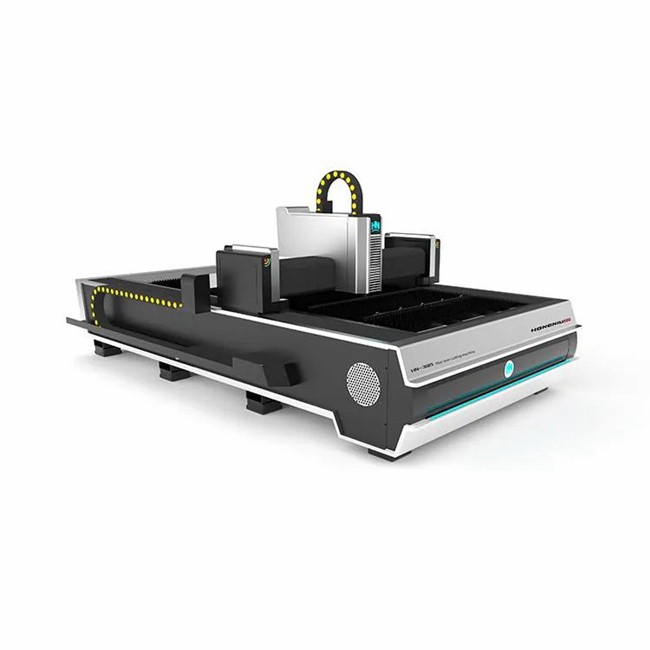

Recommended products