Filling Machines: Precision, Efficiency, and Versatility

Product description

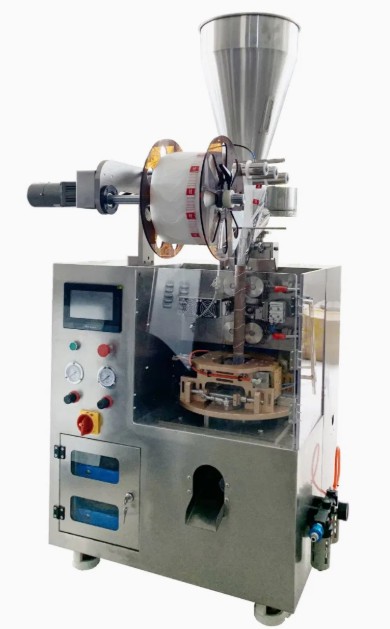

Product Introduction

Filling machines are advanced industrial equipment designed to automate the accurate dispensing of liquids, semi-liquids, pastes, powders, or granular products into containers. These machines are widely used across industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and household products. Engineered to streamline production workflows, modern filling machines cater to diverse packaging needs from small artisanal batches to high-speed industrial lines.

Available in multiple configurations, including piston fillers, gravity fillers, volumetric fillers, and auger fillers, these systems adapt seamlessly to varying product viscosities and container types (bottles, jars, tubes, pouches, etc.). Equipped with customizable settings, they ensure consistent fill volumes, minimize spillage, and integrate effortlessly with other packaging line components like capping, labeling, or sealing systems.

Key Features

1. Automated Operation: Reduce manual labor and human error with programmable controls.

2. Adjustable Parameters: User-friendly interfaces for setting fill volume, speed, and container size.

3. Material Compatibility: Constructed from high-grade stainless steel, plastics, or corrosion-resistant materials for durability and compliance with hygiene standards.

4. Scalability: Modular designs allow upgrades to meet evolving production demands.

Product Advantages

1. Precision and Consistency

Advanced sensors and precision-engineered mechanisms guarantee accurate filling within tight tolerances (±1% or better), reducing product waste and ensuring uniform packaging quality.

2. Enhanced Productivity

High-speed models can fill hundreds to thousands of containers per hour, significantly boosting output while maintaining operational reliability.

3. Versatility

Quick-changeover components enable switching between products or container sizes in minutes, making the machines ideal for multi-product facilities.

4. Hygienic Design

Tailored for food, pharmaceutical, or cosmetic applications, models feature easy-to-clean surfaces, sanitary seals, and compliance with industry regulations (e.g., FDA, GMP).

5. Cost Efficiency

Minimize material waste and labor costs while extending service life through robust construction and low-maintenance designs.

6. Sustainability

Optimized energy consumption and reduced product spillage contribute to eco-friendly operations.

7. User-Centric Innovation

Intuitive touchscreen controls, remote monitoring capabilities, and error-detection systems simplify operation and reduce downtime.

Who We Are?

Shanghai Leadworld Machinery Technology Co., Ltd. is a dynamic and innovative company specializing in the design, development, and production of high-performance industrial machinery and automation solutions, committed to delivering cutting-edge technologies and reliable equipment for global clients across manufacturing, packaging, and material handling industries. With a focus on precision engineering, energy efficiency, and smart manufacturing integration, we combine state-of-the-art R&D capabilities with rigorous quality control systems to provide tailor-made machinery solutions that optimize productivity while maintaining compliance with international standards and certifications to ensure superior performance and long-term operational value for businesses worldwide.

Recommended products