Laser Cutting Machines: Precision and Efficiency Redefined

Product description

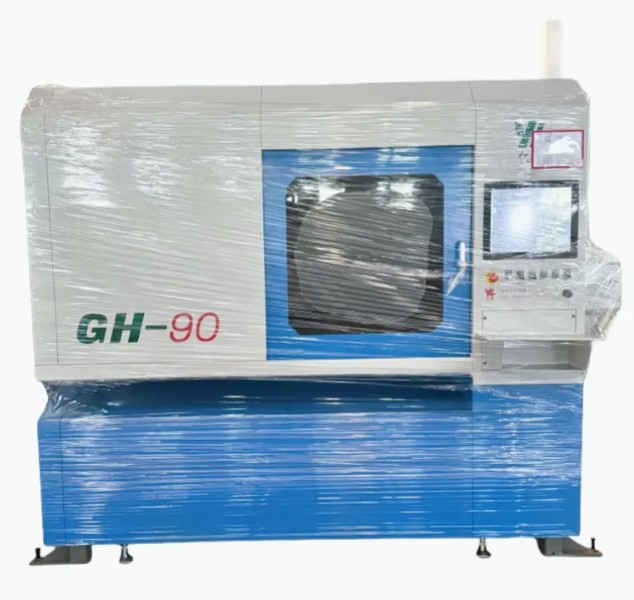

Product Overview

Laser cutting machines are advanced industrial tools designed to deliver unmatched precision, speed, and versatility in material processing. Utilizing high-powered laser beams, these machines effortlessly cut, engrave, or etch a wide range of materials, including metals (steel, aluminum, brass), plastics, wood, acrylic, glass, ceramics, and composites. Equipped with state-of-the-art CO₂ or fiber laser technology, they cater to industries such as automotive, aerospace, electronics, signage, jewelry, and custom manufacturing.

With customizable power settings and computer-controlled operation, laser cutting machines seamlessly handle intricate designs, complex geometries, and high-volume production runs. Their non-contact cutting method ensures minimal material distortion, preserving the integrity of delicate or thin materials. Compatible with CAD or CAM software, these machines enable seamless integration into automated workflows, transforming digital designs into flawless physical products.

Key Advantages

1. Ultra-High Precision

Achieve cutting tolerances as tight as ±0.1 mm, ideal for micro-detailing and complex patterns. The focused laser beam ensures clean edges and repeatable accuracy, eliminating post-processing needs.

2. Unrivaled Speed and Efficiency

Complete jobs up to 10x faster than traditional mechanical cutting methods. Rapid processing reduces lead times, boosts productivity, and lowers operational costs for high-demand environments.

3. Material Versatility

Switch effortlessly between materials without retooling. From 0.5 mm stainless steel to 30 mm wood panels, a single machine adapts to diverse projects, streamlining multi-material workflows.

4. Automation-Ready Design

Integrated sensors, auto-focus systems, and conveyor belt compatibility enable 24/7 unmanned operation. Pair with nesting software to optimize material usage, reducing waste by up to 20%.

5. Low Maintenance, High Durability

Solid-state fiber lasers (for metals) and modular CO₂ systems (for organics) require minimal upkeep. Long-life laser sources and air-cooled designs ensure years of reliable service.

6. Eco-Friendly Operation

Energy-efficient components and reduced material waste align with sustainable manufacturing goals. Fume extraction systems ensure safe and clean workspaces compliant with global standards.

7. User-Centric Interface

Intuitive touchscreen controls and cloud-based software allow operators to monitor progress, adjust parameters, and troubleshoot remotely even with limited technical expertise.

Applications Across Industries

1. Metal Fabrication: Precision-cut automotive parts, HVAC components, and decorative metal art.

2. Electronics: Micro-drilling circuit boards and crafting device enclosures.

3. Architecture: Create detailed scale models, signage, and interior decor elements.

4. Fashion: Laser-cut leather, textiles, and custom accessories with flawless finishes.

5. Packaging: Prototype or mass-produce intricate cardboard or acrylic displays.

Who We Are?

Jinan Hongniu Machinery Equipment Co., Ltd. is a trusted manufacturer and supplier of high-quality industrial machinery and equipment based in Jinan, China, specializing in the design, production, and distribution of robust machinery solutions for construction, mining, agriculture, and material handling industries. Leveraging advanced technology, a skilled engineering team, and stringent quality control systems, the company delivers durable, efficient, and cost-effective equipment tailored to meet global client needs while adhering to international standards and certifications. Committed to innovation, customer-centric service, and sustainable practices, Jinan Hongniu has established long-term partnerships worldwide, offering customized solutions, timely technical support, and reliable after-sales services to enhance operational productivity across diverse sectors.

Conclusion

Laser cutting machines represent the pinnacle of modern manufacturing technology, combining flexibility, precision, and automation to meet the demands of today’s dynamic industries. Whether for prototyping, small-batch customization, or large-scale production, they empower businesses to reduce waste, accelerate timelines, and unlock creative possibilities. Invest in a laser cutting solution to elevate your competitive edge while future-proofing your production capabilities.

Recommended products