Ceramic Electric Heaters: Intelligent & Safe Heating Technology

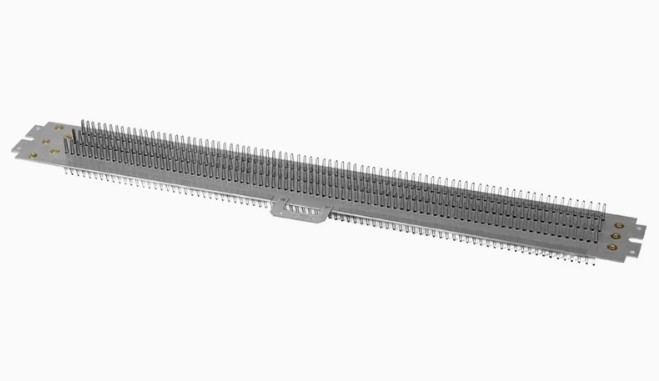

Product description

Ceramic electric heaters utilize Positive Temperature Coefficient (PTC) ceramic elements to generate efficient, self-regulating heat. When electricity passes through the specialized ceramic material, its resistance increases exponentially as temperature rises, automatically limiting power consumption once optimal heat is achieved. Unlike traditional metal coil heaters, ceramic heaters require no external temperature controls to prevent overheating. Encased in aluminum fins or integrated into compact modules, they deliver rapid, uniform heat with inherent safety.

Key Advantages

Feature Benefit

Self-Regulating Technology Reduces energy use by 30–50% vs. fixed-resistance heaters; eliminates overheating risks

Rapid Heat Transfer Aluminum fins amplify surface area, achieving operational temperature in <60 seconds

Silent & Maintenance-Free No moving parts or glowing elements; operates at <20 dB

Compact Powerhouse High power density (3–5 W/cm³) enables slim designs for space-constrained applications

Enhanced Safety Surface temperatures stay below 300°C (572°F) even during airflow failure; UL/CE certified

Core Applications

Industrial

Precision drying ovens, plastic welding equipment, 3D printer beds

Food processing conveyors, packaging sealers

Consumer & HVAC

Hair dryers, space heaters, dehumidifiers

Air curtains, duct boosters, defrosting systems

Transportation

EV battery pre-heating, cabin heaters

Mirror/defroster systems in automotive

Medical & Tech

Blood analyzers, respiratory therapy devices

Semiconductor wafer processing

Q: Why choose ceramic over traditional coil heaters?

A: Ceramic heaters self-limit temperature (no thermal runaway), use 30% less energy at steady state, and have 2x longer lifespan due to oxidation resistance.

Q: Can ceramic heaters operate in wet environments?

A: Standard units are not waterproof. Use IP65-rated sealed models for humid areas (e.g., bathrooms). Never immerse in water.

Q: What happens if dust blocks the heater fins?

A: Reduced airflow causes slower heat dissipation, triggering the PTC effect to lower power. Clean fins every 6 months with compressed air to maintain efficiency.

Q: Are ceramic heaters suitable for extreme temperatures?

A: Industrial-grade PTC ceramics withstand -40°C to 250°C ambient. For higher demands (e.g., 450°C), specify high-temp formulations.

Q: How to troubleshoot low heat output?

A: ① Verify input voltage matches rating (±10%) ② Check for loose wiring ③ Ensure airflow isn’t obstructed ④ Test thermostat function ⑤ Replace if ceramic core is cracked.

Recommended products