How To Choose The Right HDPE Box Container

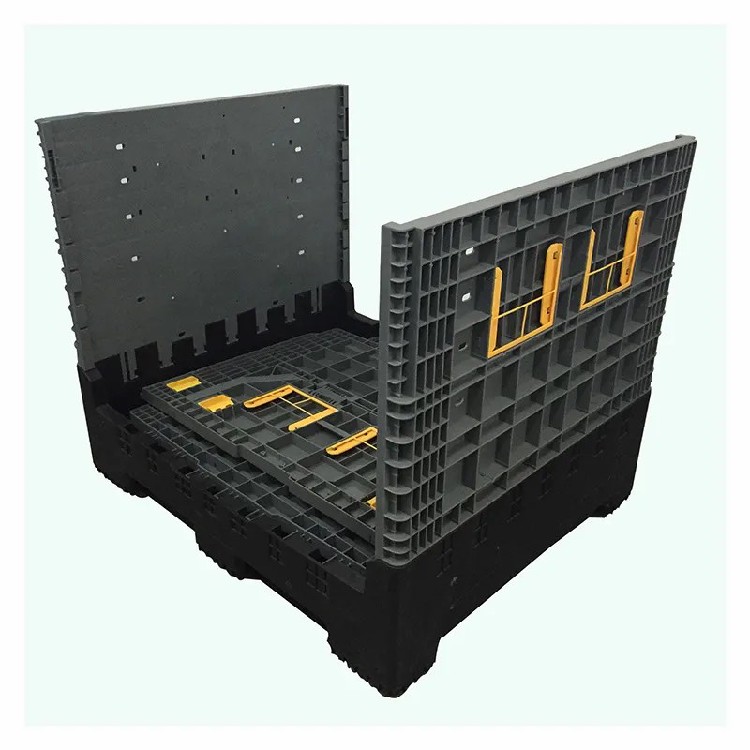

Product description

In the realm of storage and organization, not all solutions are created equal. For demanding environments where standard plastic simply won't suffice, High-Density Polyethylene (HDPE) containers emerge as the undisputed champion. Renowned for their exceptional durability and chemical resilience, these containers are engineered for those who require more than just a basic bin. They are the backbone of industries, the safeguard for valuable inventory, and the long-term organizational solution for severe conditions. This guide explores the superior properties of HDPE plastic containers, illustrating why they are the optimal choice for heavy-duty applications.

Engineered for Excellence: The Core Properties of HDPE

HDPE is a premium polymer known for its high strength-to-density ratio. This scientific description translates into a container that is incredibly tough, impact-resistant, and rigid, yet surprisingly lightweight. Unlike other plastics, HDPE possesses an innate resistance to a wide range of chemicals, including strong acids, bases, and corrosive substances. This makes it immune to degradation, staining, and odor absorption, ensuring the integrity of both the container and its contents.

The material is also highly resistant to moisture and will not rust or corrode, a critical advantage over metal alternatives. Furthermore, HDPE offers excellent performance across a broad temperature range, maintaining its structural integrity without becoming brittle in freezing conditions or warping under moderate heat. Many HDPE containers are UV-stabilized to prevent degradation from prolonged sun exposure, making them suitable for both indoor and outdoor use. The manufacturing process often results in a smooth, non-porous surface that is easy to clean and sanitize.

Why HDPE Stands Apart: Unmatched Advantages

The primary advantage of choosing an HDPE container is its unparalleled lifespan. This is a product built to last for decades, not years. Its resistance to impact means it can withstand the bumps, drops, and rough handling common in warehouses, factories, and job sites without cracking or breaking. This durability translates directly into a lower total cost of ownership, as the need for frequent replacements is eliminated.

The chemical inertness of HDPE is a game-changer for industries dealing with solvents, oils, fertilizers, cleaning agents, or automotive fluids. It provides a safe, non-reactive barrier that protects workers and the environment. From a practical standpoint, the lightweight nature of HDPE reduces worker fatigue and minimizes shipping costs compared to glass, wood, or metal containers. The smooth surfaces are also easy to label, allowing for clear identification of contents with permanent markers or printed labels.

Versatility in Action: Key Applications and Industries

The unique combination of properties makes HDPE containers indispensable across a diverse spectrum of uses. In industrial and manufacturing settings, they are used for storing raw materials, parts, and chemical products. The agricultural sector relies on them for storing fertilizers, pesticides, and animal feed. In automotive and mechanical workshops, they safely contain oils, lubricants, and degreasers.

Food processing facilities utilize food-grade HDPE containers for ingredients and intermediate products due to their easy-clean surface and compliance with safety standards. Retail and wholesale operations use them for bulk item storage and display. Beyond commerce, they are also perfect for residential storage in garages or basements for items that require superior protection from moisture and pests.

Addressing Your Queries: HDPE Container Q&A

Q1: Is HDPE safe for storing drinking water or food?

A: Yes, but only if it is explicitly certified as food-grade. Food-grade HDPE is manufactured to meet strict regulatory standards to ensure it does not leach harmful chemicals into its contents. Always verify the food-grade certification before using any container for consumables.

Q2: How does HDPE compare to PP (Polypropylene) in terms of chemical resistance?

A: Both offer excellent chemical resistance, but their performance can vary depending on the specific chemical. HDPE generally has better resistance to alcohols, acids, and bases, while PP often has a higher tolerance for aggressive solvents and operates at a higher temperature range. For most common industrial chemicals, HDPE provides superb protection.

Q3: Can HDPE containers be used in freezing temperatures?

A: Absolutely. One of the key benefits of HDPE is its ability to remain flexible and impact-resistant even in sub-zero temperatures. Unlike other materials that may become brittle and crack, HDPE is an excellent choice for cold storage, freezers, and outdoor winter environments.

Q4: Are these containers recyclable?

A: Yes, HDPE is one of the most commonly recycled plastics, categorized under resin identification code #2. The material can be collected, processed, and remanufactured into new products, contributing to a circular economy and making it an environmentally responsible choice.

Q5: What is the best way to clean an HDPE container that held chemicals?

A: First, ensure you are wearing appropriate personal protective equipment (PPE). Empty and rinse the container thoroughly. Wash it with a mild detergent and warm water, using a brush if necessary. For decontamination, a solution of water and a disinfectant compatible with HDPE can be used. Always triple-rinse with clean water and allow it to air dry completely before reuse.

Conclusion: The Definitive Choice for Demanding Durability

An HDPE plastic container is more than a storage unit; it is a long-term investment in reliability, safety, and efficiency. Its superior structural properties and exceptional resistance to harsh conditions set a benchmark that other materials struggle to meet. By choosing HDPE, you are selecting a product designed to perform flawlessly year after year, protecting valuable assets and streamlining operations in the most challenging environments. For anyone who cannot afford compromise, HDPE is the clear and logical solution.

Recommended products