High-Quality Aluminum Alloy for Industrial Doors and Windows Can be Customized in Size

Product description

In the competitive landscape of modern manufacturing, standard components often force compromises in design, efficiency, and functionality. For projects where performance and differentiation are paramount, custom aluminum extrusions provide the ultimate solution. This specialized manufacturing process transforms aluminum alloys into uniquely shaped profiles, engineered from the ground up to meet precise application requirements. Unlike selecting from a limited catalog of standard shapes, custom extrusion places the power of design entirely in the hands of engineers and product developers, enabling breakthrough innovations across industries from advanced aerospace to cutting-edge consumer electronics.

The Core Mechanics of Custom Aluminum Extrusion

The creation of a custom aluminum extrusion begins with a precisely engineered die. This tool steel component, crafted with a specific negative image of the desired profile, is the heart of the process. A cylindrical billet of heated aluminum alloy is forced through the die under immense pressure, emerging as a continuous length of shaped profile. This extrusion method allows for the production of incredibly complex cross-sections that would be impractical or impossible to achieve through other manufacturing techniques like rolling or machining. The true engineering value lies in designing a profile that integrates multiple functions. A single custom extrusion can incorporate structural strength, internal channels for wiring or coolant, integrated mounting features, and aesthetic detailing. This multifunctional approach consolidates what would otherwise be an assembly of multiple parts into one cohesive, high-strength component, streamlining the entire manufacturing workflow from prototype to final assembly.

Unlocking Tangible Business Benefits

Investing in custom aluminum extrusions delivers a compelling return on investment through several key advantages. The most significant benefit is often part consolidation. By integrating the functions of several fabricated parts into one extruded profile, businesses can dramatically reduce assembly time, lower labor costs, and minimize inventory complexity. This simplification also enhances product reliability by eliminating numerous fasteners and potential failure points.

Weight optimization is another critical advantage. Engineers can strategically place material within the profile's cross-section to maximize strength where needed and minimize weight elsewhere, leading to lighter end-products. This is crucial in transportation applications for improving fuel efficiency and in portable equipment for enhancing user ergonomics. The design freedom afforded by custom extrusion also enables superior product differentiation. Companies can create unique, signature profiles that become integral to their brand identity, setting their products apart in the marketplace. While the initial die represents an investment, the long-term savings in production efficiency, material usage, and product performance typically result in a lower total cost of ownership, especially for medium to high-volume production runs.

Diverse Applications Driving Innovation

The application of custom aluminum extrusions spans virtually every sector that values precision, strength, and lightweight design. In the transportation industry, they are essential for creating lightweight structural frames for electric vehicles, custom railcar components, and specialized trailer bodies. The aerospace sector relies on high-strength custom extrusions for critical airframe components and interior structures where every gram saved translates to significant operational savings.

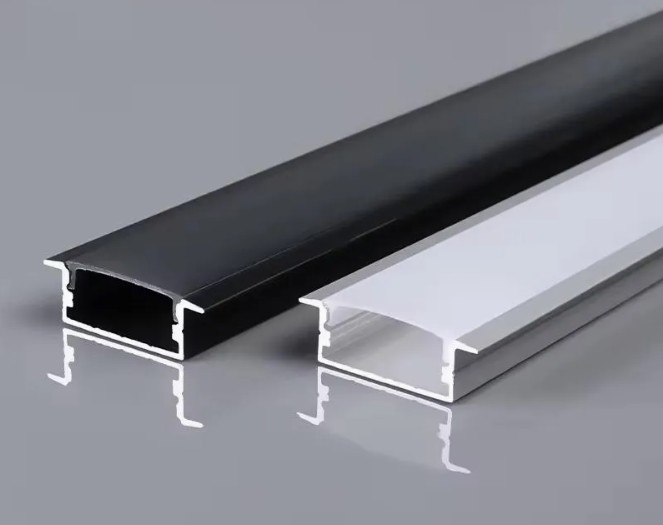

In architecture and construction, custom extrusions enable the creation of unique curtain wall systems, innovative window and door frames, and distinctive railing designs that define modern buildings. The renewable energy sector utilizes them in solar panel framing and mounting systems engineered for durability and easy installation. For industrial automation, custom profiles form the backbone of custom machine frames, conveyor systems, and safety guarding with built-in functionality. The electronics industry depends on them for specialized heat sinks in high-power LED lighting and computing equipment, as well as for the sleek, durable housings of premium consumer devices.

Addressing Key Questions About Custom Extrusions

What are the critical design considerations for a custom extrusion?

Successful custom extrusion design requires attention to wall thickness uniformity, the inclusion of generous fillets (rounded corners) to prevent stress concentration, and an understanding of how the shape will flow through the die. It is crucial to collaborate with extrusion engineers early in the design process to ensure the profile is both functional and manufacturable.

How does the alloy selection impact the final product?

The choice of aluminum alloy is fundamental to the profile's performance. Alloys from the 6000 series, particularly 6061 and 6063, are most common for extrusion, offering an excellent balance of strength, corrosion resistance, and formability. For applications requiring higher strength, 7000 series alloys may be specified, while other alloys offer improved machinability or anodizing characteristics.

What is the typical minimum order quantity for a custom extrusion?

Minimum order quantities vary by manufacturer and profile complexity. They are influenced by the cost of the custom die. While large production runs are most cost-effective, many manufacturers offer solutions for smaller batches or prototyping, though the cost per unit will be higher.

What secondary finishing operations are available?

Custom extrusions can be enhanced with a wide range of secondary operations. These include precision cutting to length, drilling, milling, threading, and bending. Surface finishes such as anodizing (for corrosion resistance and color), powder coating (for durable color and texture), and mechanical brushing or polishing are commonly applied to meet aesthetic and functional requirements.

How sustainable is the custom extrusion process?

Aluminum is one of the most recyclable industrial materials. The extrusion process itself is highly efficient, with scrap metal being routinely recycled back into the production cycle. The long service life and durability of aluminum products, combined with their full recyclability at end-of-life, contribute to an excellent environmental profile.

Conclusion: Engineering Without Compromise

Custom aluminum extrusions represent a paradigm shift from adapting to available parts to creating exactly what a project demands. They empower engineers to design with unparalleled freedom, optimizing for performance, efficiency, and aesthetics simultaneously. By embracing the possibilities of custom extrusion, businesses can develop products that are not only lighter and stronger but also more cost-effective to manufacture and distinct in the marketplace. In an era of intense competition, the strategic use of custom aluminum extrusions is a powerful tool for turning innovative concepts into market-leading realities.

Recommended products