A Deep Dive into Plastic Packaging Bags

Product description

In the intricate dance of global commerce and daily life, few components are as ubiquitous yet underappreciated as the plastic packaging bag. Far more than a simple sack, this versatile product is a marvel of modern material science, engineered to protect, preserve, and promote a vast array of goods. From safeguarding the food we eat to ensuring products arrive in pristine condition, plastic packaging bags are an indispensable part of the supply chain. This comprehensive guide explores the sophisticated features, multifaceted advantages, and diverse applications of this foundational packaging solution.

Engineered for Performance: Core Characteristics

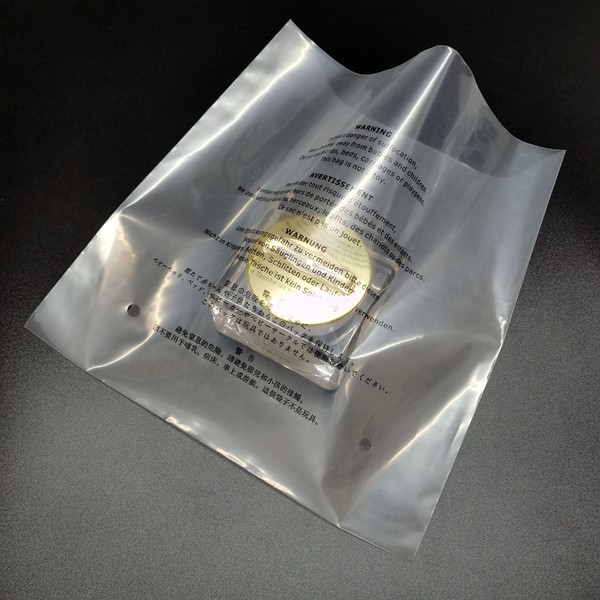

The modern plastic packaging bag is a testament to precision engineering. Its fundamental composition typically involves polymers like polyethylene (PE) or polypropylene (PP), which are selected for their specific properties. These materials are extruded into thin, flexible films that can be customized into a spectrum of strengths, clarities, and thicknesses to meet exact needs. A key feature is the heat seal, which creates a strong, airtight, and tamper-evident closure, ensuring the contents remain secure from the production line to the end-user.

Beyond basic construction, these bags can be enhanced with a range of specialized characteristics. Many are designed with barrier properties, incorporating layers that block oxygen, moisture, and light, which is critical for extending the shelf life of perishable foods and sensitive pharmaceuticals. Others feature advanced closure mechanisms, such as resealable zipper tracks, which allow for repeated access while maintaining interior freshness. Furthermore, the surfaces are often treated to be printable, enabling high-quality branding, and essential information, and compliance labeling that communicates directly with the consumer.

Delivering Tangible Value: The Multifaceted Advantages

The widespread adoption of plastic packaging bags is driven by a compelling set of advantages that benefit businesses, consumers, and the environment. Foremost among these is their exceptional protective quality. They act as a formidable shield against contaminants, moisture, dust, and physical damage during transit and on the shelf. This directly translates to reduced product loss and waste, particularly in the food industry, where preserving freshness is paramount.

From an economic and logistical perspective, the benefits are equally profound. Plastic bags are incredibly lightweight, which drastically cuts down on shipping weight and associated fuel costs compared to rigid alternatives like glass or metal. Their flexible nature allows for highly efficient space utilization, both when empty and when filled, maximizing storage and transportation capacity. For the consumer, this results in lower overall costs and unparalleled convenience—bags are easy to carry, simple to open, and often reusable for household storage. Their durability and water resistance make them a reliable choice for a multitude of tasks.

A World of Applications: Where You Find Plastic Packaging Bags

The utility of plastic packaging bags spans virtually every industry. In the food and beverage sector, they are the go-to solution for everything from fresh produce and baked goods to frozen vegetables and snacks, providing a critical barrier against spoilage. In retail, they serve as the primary packaging for a vast range of non-food items, including clothing, hardware, stationery, and electronics components, offering protection and serving as a mobile billboard for brand messaging.

Beyond these common uses, specialized bags play vital roles in other fields. The pharmaceutical industry relies on sterile, tamper-evident plastic pouches to package medical devices, swabs, and single-dose medications. In the e-commerce and logistics realm, durable mailing bags and poly mailers have become the standard for shipping small to medium-sized items, prized for their lightweight nature and resistance to the rigors of the delivery process. Even in industrial settings, heavy-duty versions are used for parts, chemicals, and raw materials.

Addressing Common Inquiries: Plastic Packaging Bag Q&A

Q1: Are there environmentally friendly options for plastic packaging bags?

A1: Yes, the industry has made significant strides in sustainability. Options now include bags made from recycled materials (post-consumer resin, or PCR), and bio-based plastics derived from renewable resources like corn starch. Furthermore, many bags are designed to be recyclable where facilities exist, and advancements are continuously being made in creating biodegradable and compostable formulations for specific applications.

Q2: How is the strength of a plastic packaging bag determined?

A2: The strength, often referred to as its gauge or mil thickness, is a key factor. However, the type of polymer and the manufacturing process are equally important. Bags can be reinforced to be puncture-resistant or tear-resistant, making them suitable for sharp or heavy items. The choice of strength is a balance between the required durability and the goal of minimizing material usage.

Q3: Can these bags be customized for specific business needs?

A3: Absolutely. Customization is a major advantage. Businesses can specify the exact size, shape, color, and thickness. High-quality printing allows for full-color logos, graphics, and instructional text to be applied directly to the bag, transforming it from simple packaging into a powerful marketing tool that enhances brand recognition.

Q4: What is the difference between a poly bag and a zipper bag?

A4: A poly bag is a general term for a bag made of polyethylene, typically sealed with a heat weld and intended for single-use access. A zipper bag, often a type of poly bag, incorporates a resealable plastic track that interlocks, allowing the bag to be opened and closed multiple times. This makes zipper bags ideal for products consumed over time, like food items or hardware components.

Q5: How should I dispose of plastic packaging bags responsibly?

A5: The first step is to check local recycling guidelines, as these vary by municipality. Many plastic bags, particularly those made of LDPE or HDPE, are recyclable at designated drop-off locations, often found in grocery stores. Reusing bags for other purposes, such as waste bin liners or for storing items, extends their life and reduces immediate waste. Always ensure bags are clean and dry before recycling.

The Integral Component in a Complex World

Plastic packaging bags are a foundational element of modern logistics and consumer convenience. Their evolution from a simple wrapper to a high-performance, customizable, and increasingly sustainable solution demonstrates their critical role. By understanding their engineered features, clear benefits, and vast applications, it becomes evident that these bags are a key innovation in preserving product integrity, reducing waste, and efficiently moving goods across the globe. They are, in every sense, the unseen engine that keeps commerce flowing smoothly.

Recommended products