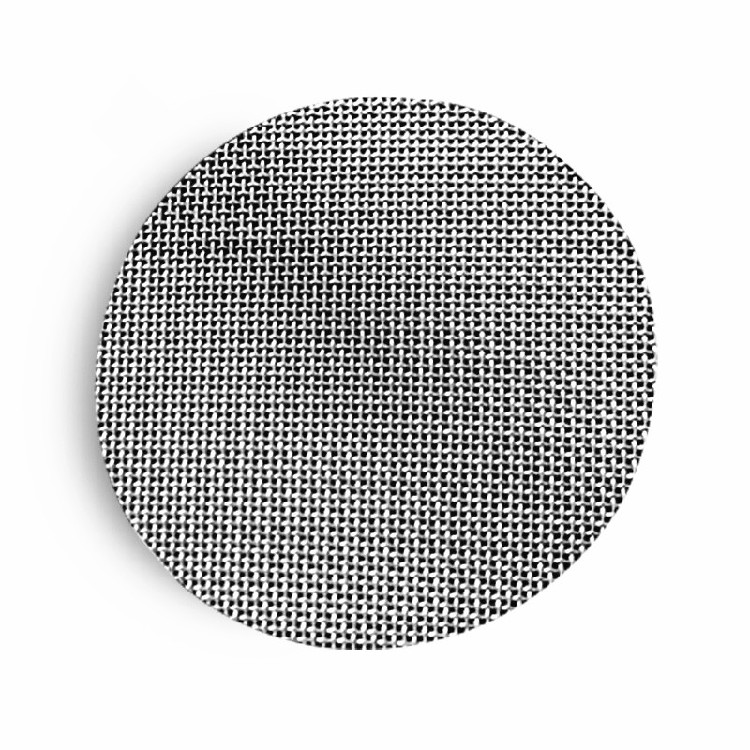

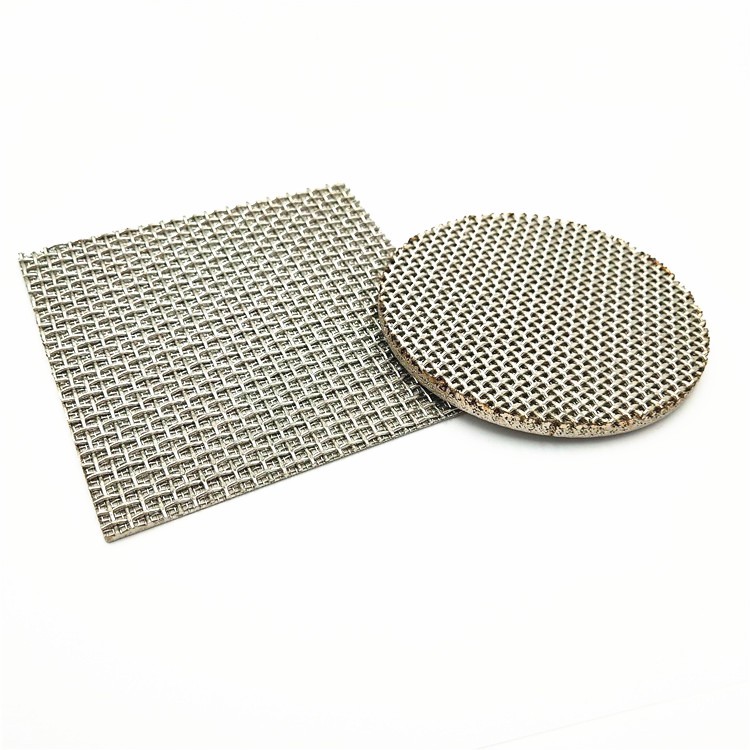

30um Stainless Steel Sintered Mesh Filter Disc

Product description

Key features for sintered filter mesh disc

1,High Porosity – Allows for controlled gas or liquid flow.

2,Mechanical Strength – Retains structural integrity under pressure.

3,Heat & Corrosion Resistance – Often made from stainless steel, nickel, or other alloys.

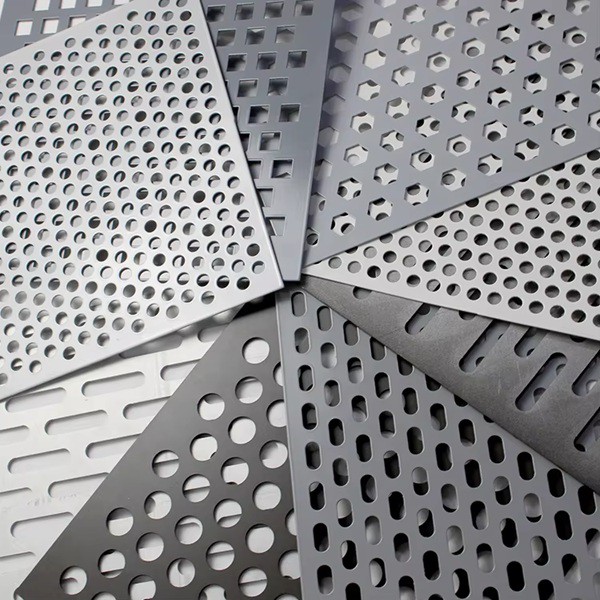

4,Filtration Efficiency – Can be customized for different particle retention levels.

5,Uniform Structure – Provides consistent performance in filtration and diffusion.

Common materials used:

1,Stainless Steel (SS 304, 316, etc.) – For corrosion resistance.

2,Nickel & Nickel Alloys – For high-temperature applications.

3,Copper & Bronze – For conductivity and anti-microbial properties.

4,Titanium – For extreme chemical resistance.

Applications of Sintered Woven Wire Mesh:

1,Filtration Systems

Air, gas, and liquid filtration (e.g., fuel filters, hydraulic systems).

Chemical processing and pharmaceutical industries.

2,Fluidization & Diffusion

Used in fluidized beds, spargers, and aerators.

3,Flame Arrestors

Prevents flame propagation in gas pipelines.

4,Sound & Vibration Damping

Used in acoustic applications due to its porous structure.

5,EMI/RFI Shielding

Provides electromagnetic interference shielding in electronics.

6,Battery & Fuel Cell Components

Used as gas diffusion layers in fuel cells.

Advantages Over Other Filters:

1,Longer lifespan than non-sintered mesh or polymer filters.

2,Can be cleaned & reused (backwashing, ultrasonic cleaning).

3,Stable structure—no media migration or shedding.

Recommended products