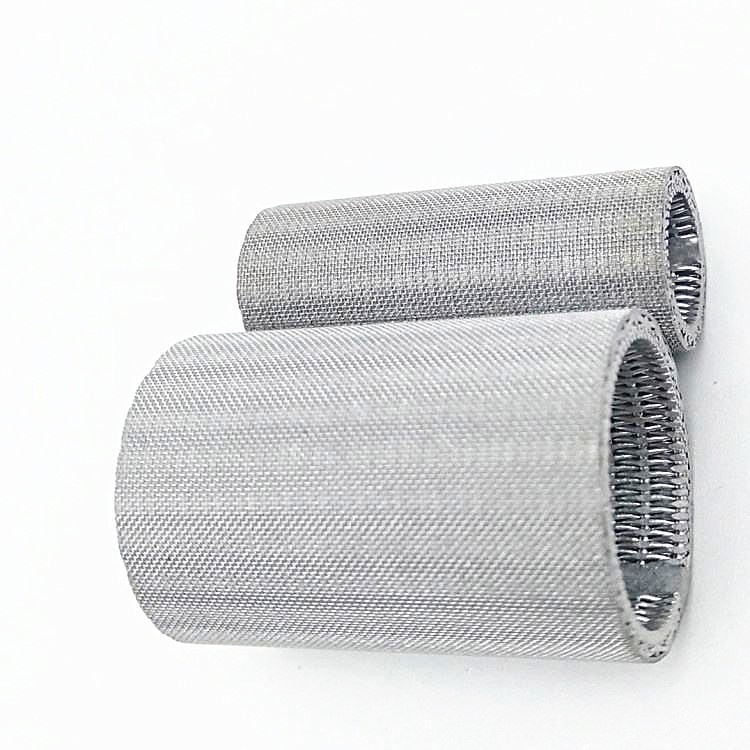

Customzied Sintered Mesh Filter Tube

Product description

Key Characteristics and Advantages

1.High Structural Strength & Rigidity: Unlike simple Woven Wire Mesh, the sintered structure is self-supporting and can withstand high pressure differentials, vibration, and mechanical stress without collapsing or deforming.

2.Excellent Filtration Performance:

1)Precise and Uniform Pore Size: The pore size can be tightly controlled during manufacturing, allowing for precise filtration ratings (e.g., 1, 5, 10, 40, 100 microns).

2)Depth Filtration: Contaminants are captured throughout the entire thickness of the tube wall, not just on the surface. This allows them to hold a significant amount of dirt before needing service, resulting in a longer service life.

3.High Temperature and Pressure Resistance: Made from metals like 304/316L stainless steel, nickel, or Inconel, they can operate in extremely high-temperature and high-pressure environments where plastic filters would fail.

4.Good Permeability and Low Flow Resistance: The interconnected pores create a path of least resistance, allowing for high flow rates with a relatively low pressure drop.

5.Easy to Clean and Reusable: They can often be cleaned back to near-original performance using methods like backflushing, ultrasonic cleaning, or chemical cleaning, making them a cost-effective, long-term solution.

6.Corrosion Resistance: When made from stainless steel or other alloys, they resist corrosion from a wide range of chemicals and solvents.

Recommended products