board

Product description

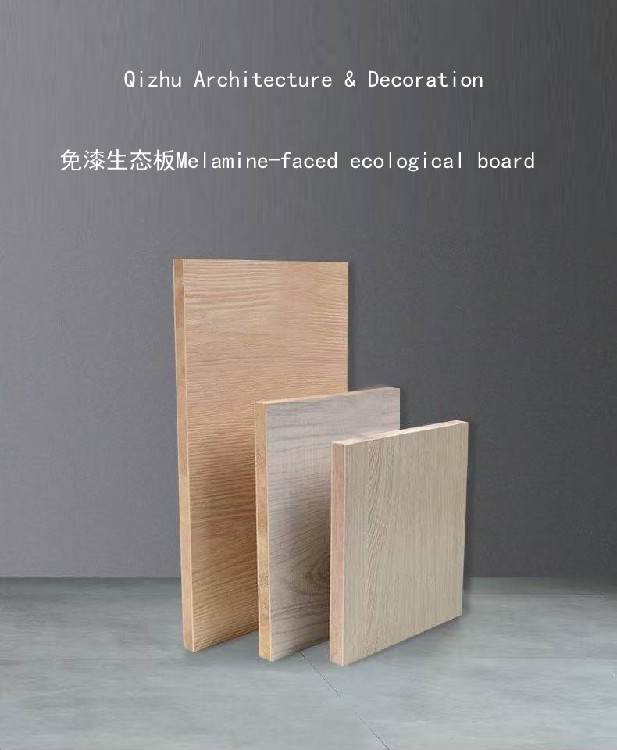

Product Specification: Ecological Board (Melamine-Faced Board)

Product Name: Ecological Board / Melamine-Faced Chipboard (MFC) / Melamine-Faced Board (MFB)

Brand: Qizhu

1. Product Overview

This ecological board is a high-performance decorative panel widely recognized in the global furniture and construction industries. With a core substrate as its base, it is manufactured by bonding melamine-impregnated decorative paper to the substrate through high-temperature and high-pressure processing. Combining environmental friendliness, durability, and aesthetic appeal, the product requires no additional painting, making it an ideal choice for efficient and healthy interior decoration and furniture production.

2. Core Features

2.1 Excellent Environmental Performance

- The substrate complies with E1 and E2 formaldehyde emission standards (formaldehyde emission: ≤0.124mg/m³ - ≤0.3mg/m³), meeting China's GB 18580-2017 standard and the European Union's EN 13986 standard. It also satisfies the requirements of the U.S. CARB P2 certification, with low formaldehyde emission, ensuring safe use in indoor spaces.

- No paint or harmful solvents are used in the production process, achieving "zero pollution" during installation and use, allowing for immediate occupancy after decoration.

- 2.2 Outstanding Physical and Chemical Properties

- Surface hardness: ≥6H (scratch-resistant, impact-resistant, and wear-resistant, maintaining a intact surface even after long-term use).

- Good moisture resistance: 24-hour water absorption rate ≤8%, suitable for humid environments such as kitchens and bathrooms.

- Strong dimensional stability: Low thermal expansion and contraction coefficient, preventing deformation and cracking under changes in temperature and humidity, especially suitable for the standard size of 1220×2440mm.

- Easy to clean and stain-resistant: The smooth surface allows for easy removal of stains such as oil and ink with a damp cloth.

- 2.3 Rich Decorative Effects

- Over 50 surface patterns available: Covering simulated solid wood textures (oak, walnut, maple, etc.), solid colors, fabric textures, and stone textures, all compatible with both 14mm and 18mm thicknesses.

- High color consistency between batches: When using the standard 1220×2440mm size for large-scale project construction, uniform overall decorative effects can be ensured.

- Optional surface gloss: Matte, semi-matte, and glossy finishes are available to meet the needs of different thickness panels in various design scenarios.

- 2.4 High Processing Convenience

- Compatible with conventional woodworking processes: Panels with 14mm and 18mm thicknesses can be processed through cutting, drilling, edge banding, and routing using standard equipment.

- Strong interlayer bonding force: The substrate and decorative layer are firmly bonded. Even for large-sized panels of 1220×2440mm, there will be no delamination or peeling during processing and use.

- 3. Technical Specifications

- ItemSpecificationSize1220×2440×14mm / 1220×2440×18mmSubstrateMulti-layer plywoodThickness14mm, 18mm (customizable for special requirements)Sheet Size1220×2440mm (standard size, stable supply)Surface TreatmentMelamine-faced (matte / semi-matte / glossy)Formaldehyde EmissionE1 Grade (≤0.124mg/m³) / CARB P2 CertificationDensity (Particle Board Substrate)650-750 kg/m³ (applicable to both 14mm and 18mm thicknesses)Bending Strength≥15MPa (meets the load-bearing requirements of 14mm and 18mm thick panels)Internal Bond Strength≥0.35MPa (ensures structural stability of 1220×2440mm size panels)24-Hour Water Absorption≤8%

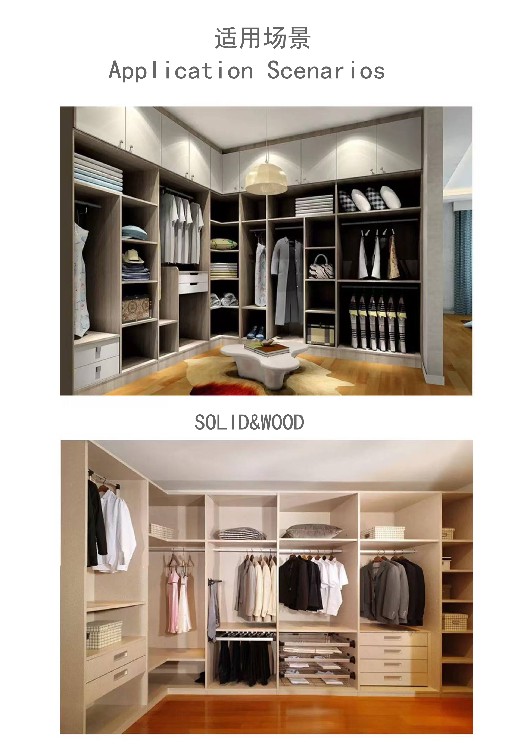

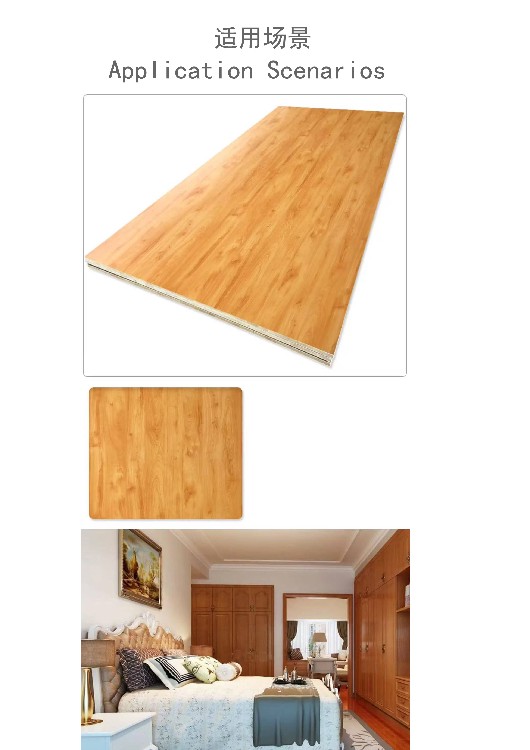

- 4. Application Scenarios

- 4.1 Residential Furniture Field

- 18mm thickness: Using the standard 1220×2440mm size to produce main panels for whole-house custom furniture (wardrobes, cabinets, bookcases, TV stands, bed frames, etc.).

- 14mm thickness: Used for door casings, window casings, wall panels, and secondary structural components of furniture. Compatibility with the standard size simplifies the assembly process.

- 4.2 Commercial Space Field

- 18mm thickness: Using large-sized 1220×2440mm panels to make large-area panels for shopping mall display cabinets and office furniture (desks, filing cabinets).

- 14mm thickness: Used as auxiliary panels for hotel furniture and restaurant interior decoration, ensuring quality while balancing cost-effectiveness.

- 4.3 Architectural Decoration Field

- 18mm thickness: Used for partition panels, ceiling panels, and decorative wall claddings. The 1220×2440mm size reduces seams and achieves a seamless installation effect.

- 14mm thickness: Suitable for auxiliary furniture around kitchens and bathrooms, meeting the installation needs of narrow spaces while maintaining the proportional coordination of the standard sheet size.

- 5. Packaging and Logistics

- Packaging Method: Each 1220×2440mm panel (including 14mm and 18mm thicknesses) is covered with a PE film to prevent scratches. The outer layer is bound with waterproof kraft paper and reinforced with wooden pallets to ensure the standard size remains undamaged during transportation.

- Loading Quantity:

- 20ft container: 900-1100 pieces for 14mm thickness, 800-1000 pieces for 18mm thickness (calculated based on the standard 1220×2440mm size).

- 40ft container: 1900-2300 pieces for 14mm thickness, 1800-2200 pieces for 18mm thickness (calculated based on the standard 1220×2440mm size).

- Production Lead Time: 7-15 working days after order confirmation (bulk orders for 14mm/18mm thickness + 1220×2440mm size can have a shorter lead time through negotiation).

- Shipping Terms: FOB (Free On Board), CIF (Cost, Insurance and Freight), CFR (Cost and Freight) are supported, and can be customized according to customer requirements.

- 6. Quality Assurance

- Warranty Period: A 5-year quality warranty is provided for ecological boards with 14mm/18mm thickness and 1220×2440mm size, covering manufacturing defects (such as delamination, cracking, fading under normal use).

- Quality Control Process: Strict quality control is implemented throughout the production process, from raw material inspection to finished product testing, with a focus on verifying the thickness uniformity (14mm, 18mm) and size accuracy (1220×2440mm) of the panels.

- Sample Service: Free samples are available (14mm, 18mm thickness, cut pieces of 1220×2440mm size). Customers only need to bear the shipping cost, facilitating quality verification before bulk purchase.

- 7. Contact Information

- For inquiries, quotations, or sample requests (specifically for E1 Grade ecological boards with 14mm/18mm thickness + 1220×2440mm size), please contact:

- Company Name: Qizhu Architecture & Decoration

- Company Address: Linyi (Shandong), China

- Contact Person: Mr. Jin

- Phone Number: +8618653981308

- Email Address: qizhu1818@yeah.net

- WhatsApp: qizhu1818@yeah.net

- We sincerely invite global distributors, wholesalers, and project partners to join hands and create cooperative opportunities for E1 Grade ecological boards with 14mm/18mm thickness and 1220×2440mm size!

Company profile

Lanshan District Qizhu Construction Decoration Department (Individual Household)

Recommended products