Anti-crush Safety Shoes Offer You The Greatest Safety Protection

Product description

In workplaces where heavy objects, falling tools, or rolling equipment are part of the daily grind, foot protection isn't just a recommendation—it's an absolute necessity. Safety toe shoes, commonly known as steel toe or composite toe boots, are engineered specifically to create a formidable barrier between your feet and workplace hazards. This essential gear goes far beyond standard footwear, integrating advanced protective features to prevent crushing injuries and ensure you can perform your duties with confidence and security. Understanding the technology, benefits, and right application of these shoes is the first step toward a safer work environment.

What Exactly Are Safety Toe Shoes?

At their core, safety toe shoes are protective footwear designed with a reinforced toe cap. This cap is the primary defense mechanism against impact and compression. While many people immediately think of the traditional steel toe, modern advancements have introduced a variety of materials, including lightweight composite materials and aluminum. These shoes are not just about the toe cap; they often form part of a larger system of protection that may include puncture-resistant midsoles, electrical hazard protection, and slip-resistant outsoles. They are rigorously tested to meet or exceed stringent international safety standards, ensuring they perform as expected in critical situations.

Core Protective Features That Matter

The effectiveness of a safety shoe is defined by its integrated features. The most critical component is, of course, the safety toe cap. This internal reinforcement is designed to withstand a significant amount of force, effectively preventing serious injuries to the toes from falling objects. Another vital feature is the puncture-resistant midsole. This is a thin, yet incredibly tough, layer placed between the insole and outsole that stops sharp objects like nails or shards of metal from penetrating through the bottom of the shoe.

Furthermore, the outsole's design is crucial for stability and safety. Slip-resistant soles provide enhanced grip on oily, wet, or slick surfaces, drastically reducing the risk of slips and falls. For those working around electrical circuits, shoes with Electrical Hazard (EH) protection offer a secondary layer of defense against open circuits. Additionally, many models offer metatarsal guards, which protect the delicate bones on the top of the foot, and ergonomic insoles that provide all-day comfort, reducing fatigue during long shifts.

Significant Advantages Beyond Basic Protection

The most obvious advantage of wearing safety toe shoes is the prevention of catastrophic foot injuries. They are a fundamental part of personal protective equipment (PPE) protocols on job sites. However, the benefits extend further. By meeting the required safety standards, these shoes help both employers and employees stay compliant with occupational health and safety regulations, avoiding potential fines and liabilities.

Modern safety shoes are also a testament to how far design has come. Gone are the days of clunky, uncomfortable boots. Today's options are sleek, lightweight, and often indistinguishable from regular athletic shoes or casual footwear, making them suitable for a wider range of environments. This improved design, coupled with features like moisture-wicking linings and supportive arch designs, significantly enhances wearer comfort, which in turn can boost productivity and morale. Ultimately, investing in quality safety footwear is an investment in long-term well-being and professional efficiency.

Ideal Applications and Work Environments

Safety toe shoes are indispensable across a broad spectrum of industries. Construction sites are a primary example, where the risk of heavy building materials, tools, or equipment falling on feet is a constant concern. In manufacturing and warehouse settings, workers handling heavy parts, operating machinery, or moving pallets rely on this footwear for protection against rolling objects and impacts.

The industrial and mechanical sectors, including automotive repair and metalworking, benefit from the combination of toe protection and puncture resistance. Even in less traditional settings like laboratories where heavy containers might be handled, or in electrical utilities where EH rating is critical, these shoes provide essential safety. Essentially, any professional environment where the feet are exposed to potential harm is an environment that calls for certified safety toe footwear.

Your Safety Toe Shoe Questions, Answered

Q1: What is the difference between steel toe and composite toe?

A1: Steel toes are made from heavy-duty steel and are known for their strong, thin profile. Composite toes are typically made from non-metal materials like Kevlar, fiberglass, or plastic. They are lighter, do not conduct temperature (making them better in extreme hot or cold), and are metal-free, which is advantageous for airport security or certain industrial settings.

Q2: Are these shoes as comfortable as regular shoes?

A2: Absolutely. Modern safety shoes are designed with comfort in mind. Many feature the same cushioning technology, breathable materials, and ergonomic designs found in high-quality athletic shoes, ensuring you can wear them comfortably throughout the workday.

Q3: How do I know if my safety shoes are certified?

A3: Look for a marking inside or on the tongue of the shoe. Common certifications include ASTM F2413 (USA) or EN ISO 20345 (Europe). These labels will specify the exact protections the shoe offers, such as impact resistance (I/75), compression (C/75), and electrical hazard safety (EH).

Q4: Can safety shoes really protect against all impacts?

A4: They are designed and tested to protect against specific standards of impact and compression. For instance, a common standard requires the toe cap to withstand an impact of 75 foot-pounds and 2,500 pounds of compression. However, they are not indestructible and cannot protect against forces that exceed their rated capacity.

Q5: Do I need to replace my safety shoes after a heavy impact?

A5: Yes, it is highly recommended. Even if there is no visible damage, the internal structure of the toe cap may be compromised, reducing its ability to protect you in a future incident. Inspect your footwear regularly and replace it following any significant impact.

Q6: Are there safety shoes that are also waterproof?

A6: Yes, many models come with waterproof membranes, such as Gore-Tex, that keep your feet dry in wet conditions while still providing all the necessary safety features.

Q7: How should a proper safety shoe fit?

A7: They should fit snugly but not tightly, with enough room to wiggle your toes. Your heel should not slip, and the widest part of your foot should align comfortably with the widest part of the shoe. Always try them on with the type of work socks you typically wear.

Q8: Can I get stylish safety shoes?

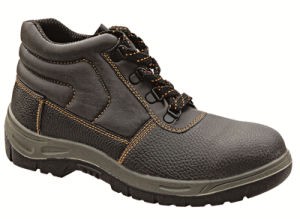

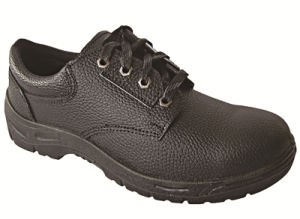

A8: Certainly. The market now offers a wide variety of styles, from classic work boots to low-cut sneakers and even casual oxfords, allowing you to meet safety requirements without sacrificing your personal style.

Q9: Do composite toes set off metal detectors?

A9: No, one of the key advantages of composite safety toes is that they are non-metallic and will not activate walk-through metal detectors, making them ideal for security personnel or workers in secured facilities.

Q10: How long do safety shoes typically last?

A10: The lifespan depends on the work environment and frequency of use. A general guideline is to replace them every 6 to 12 months with regular, heavy use, or as soon as you notice signs of significant wear on the sole or upper material.

Recommended products