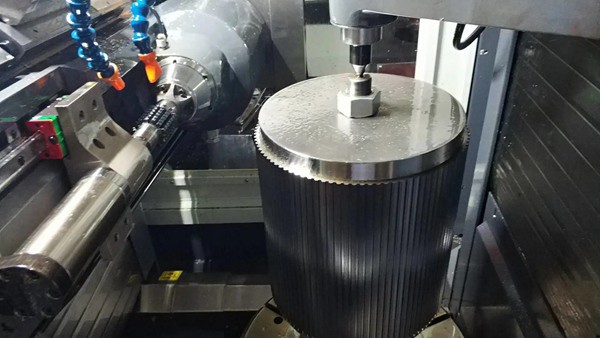

China Factory Direct Gear Hobbing Hobber Machine for Bevel Gear Cutting Milling Processing

Product description

Gear hobbing machines can process gears of various shapes and specifications, including straight teeth, helical teeth, bevel teeth, etc. This wide adaptability enables gear hobbing machines to meet the gear processing needs of different industries. Modern gear hobbing machines adopt advanced CNC technology, making operation more convenient and intuitive. Operators only need to input the corresponding processing parameters to achieve automated processing.

Gear hobbing machines have a high degree of automation and can achieve continuous and high-speed machining of gears. Compared to traditional cutting methods, gear hobbing machines have higher production efficiency, which helps to reduce production costs. The gear hobbing machine adopts rolling cutting method, which causes less damage to the gear surface and can maintain the smoothness and accuracy of the gear surface. This processing method helps to extend the service life of gears.

The gear hobbing machine adopts the generation method to process gears, which can accurately control the tooth shape and modulus of the gears, ensuring the accuracy of the gears. This high-precision machining method helps to improve the transmission efficiency and service life of gears.

Gear hobbing machines are widely used in various mechanical manufacturing industries such as automobiles, tractors, machine tools, engineering machinery, mining machinery, metallurgical machinery, petroleum, instruments, aircraft, and spacecraft. It can meet the machining needs of various cylindrical gears, bevel gears, and other toothed parts, providing high-quality gear transmission components for various mechanical equipment. The gear hobbing machine disperses cutting force at multiple rolling points through the rolling motion of the rollers, enabling high accuracy in the tooth shape and modulus of the gears. This high-precision machining method ensures the transmission efficiency and quality of gears.

Gear hobbing machines can be divided into two types according to layout: vertical and horizontal. Large and medium-sized gear hobbing machines are mostly vertical, while small gear hobbing machines and gear hobbing machines specifically designed for processing long shaft gears are both horizontal. Vertical gear hobbing machines are divided into two types: worktable movement and column movement. In practical applications, choose the appropriate type of gear hobbing machine based on processing requirements and workpiece characteristics.

Recommended products