China Supply Spray Head Bottle Liquid Filling Machine with CE and ISO

Product description

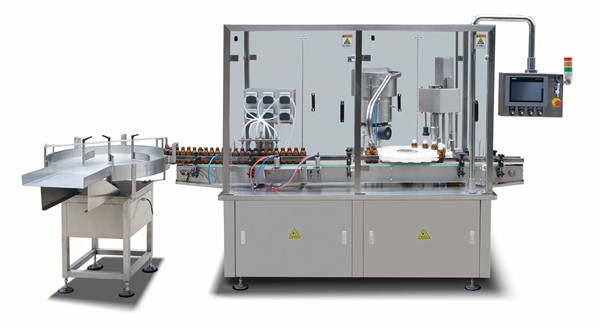

Liquid filling machines can further improve the automation level of equipment, reduce manual intervention, lower production costs, and improve production efficiency. Pay attention to environmental protection requirements such as energy conservation, emission reduction, and waste disposal, and promote the green manufacturing and use of equipment. Provide more personalized customized services based on customer needs and market changes to meet their special needs.

With the continuous progress of technology and the constant changes in the market, liquid filling machines are also constantly developing and innovating. Future liquid filling machines will place greater emphasis on intelligence, automation, and environmental friendliness. By introducing technologies such as the Internet of Things, big data, and artificial intelligence, remote monitoring, fault diagnosis, and automatic adjustment of equipment can be achieved, improving the intelligence level of the equipment.

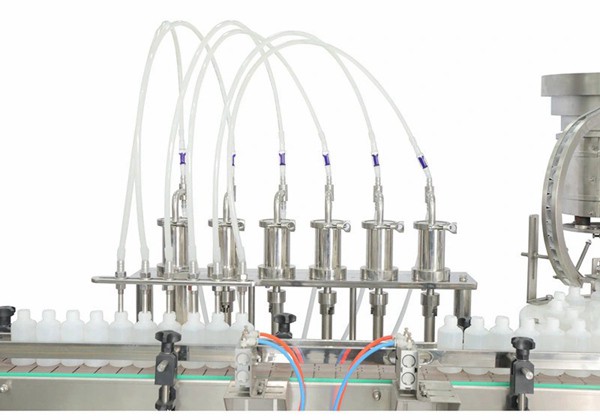

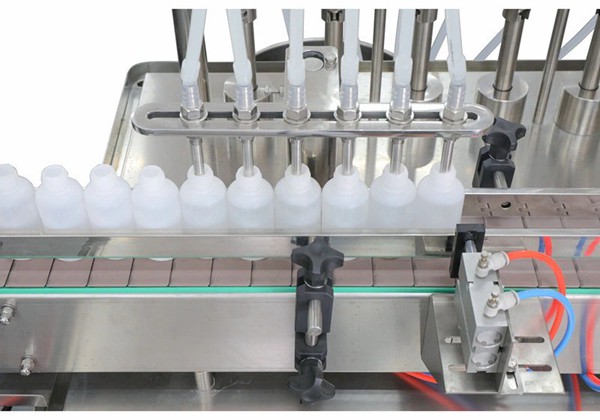

The working principle of liquid filling machines is relatively simple, but in practical operation, high precision and stability are required. Its main components include a storage tank, a conveying pump, a metering device, a filling head, and a control system. Firstly, the liquid is extracted from the storage tank through a transfer pump, filtered and regulated before entering the metering device. The measuring device accurately measures the preset filling amount and then injects the liquid into the container through the filling head. Throughout the process, the control system is responsible for monitoring and adjusting each link to ensure the accuracy and stability of filling.

In modern and automated industrial production, liquid filling machines play a crucial role. Whether in the food, beverage, cosmetics, or chemical industry, liquid filling machines are one of the key equipment to ensure product quality and improve production efficiency. This article will provide a detailed introduction to the working principle, characteristics, application areas, and future development trends of liquid filling machines.

Recommended products