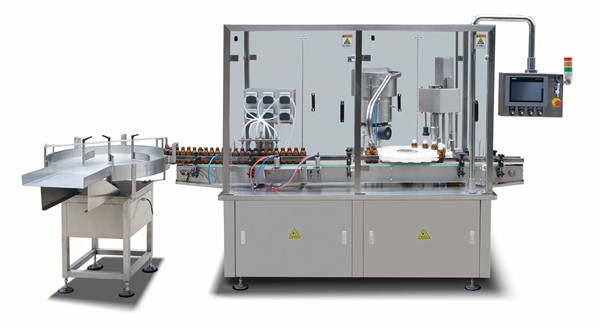

Automatic Spray Filling Capping Machine with CE and ISO

Product description

As one of the important equipment in modern industrial production, liquid filling machines will continue to play an important role in improving production efficiency and ensuring product quality. Meanwhile, with the continuous progress of technology and changes in the market, liquid filling machines will also continue to develop and innovate, providing more efficient, accurate, and environmentally friendly liquid packaging solutions for various industries.

Application field:

Food industry: filling of beverages, jams, seasonings, etc.

Beverage industry: filling of various bottled and canned beverages.

Chemical industry: filling of paints, coatings, inks, etc.

Cosmetic industry: filling of products such as shampoo, shower gel, skincare products, etc.

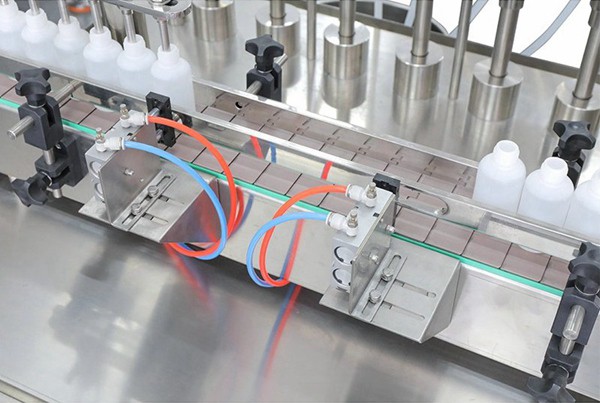

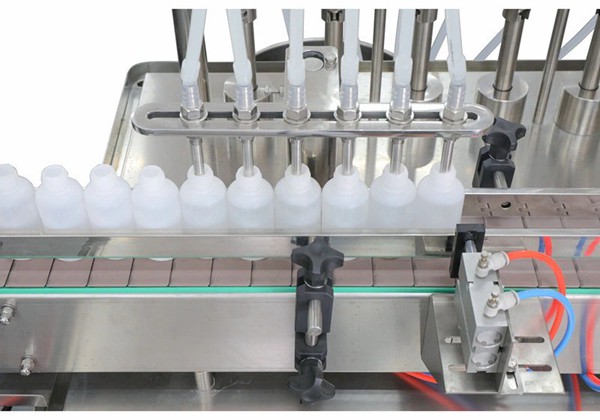

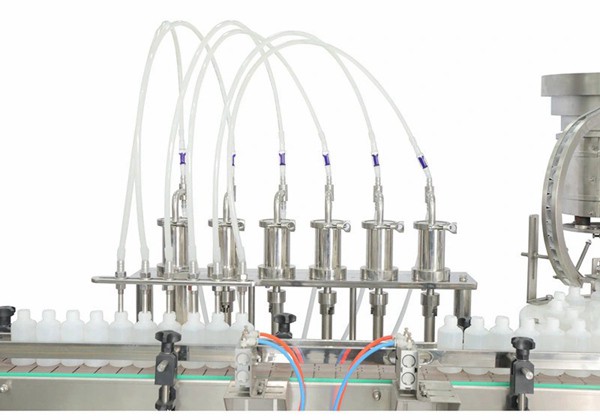

The capping filling machine adopts automatic control, which can achieve high-speed and continuous filling and capping operations, greatly improving production efficiency. By using high-precision measuring devices and control systems, we ensure that the amount filled each time meets the preset standards, reducing waste and errors. The capping and filling machine is suitable for various liquid products, such as beverages, cosmetics, food, etc., and can adapt to bottle caps of different shapes and sizes. The equipment is manufactured using high-quality materials and advanced technology to ensure stability and reliability during long-term operation.

The capping and filling machine can automatically seal according to the size and shape of the bottle cap, reducing manual operation errors and labor intensity. Some capping and filling machines also have automatic detection functions to ensure the sealing degree and correctness of bottle caps, reducing losses caused by poor sealing. The equipment can automatically transport filled liquid products, as well as automatically transport and seal bottle caps, improving the overall production capacity and stability of the production line.

Recommended products