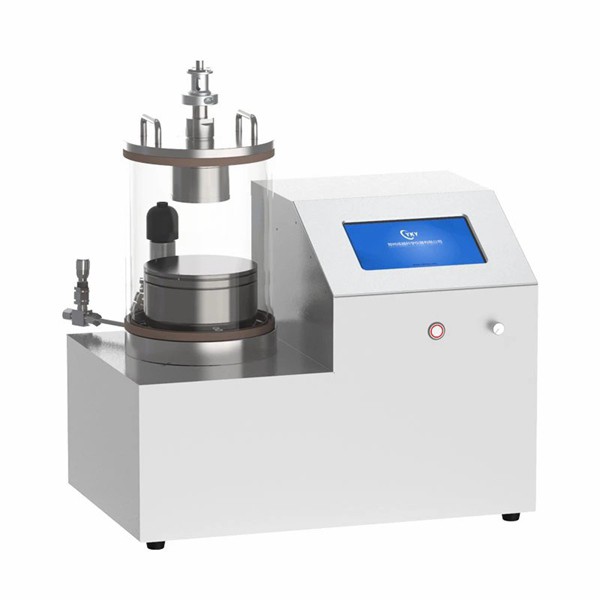

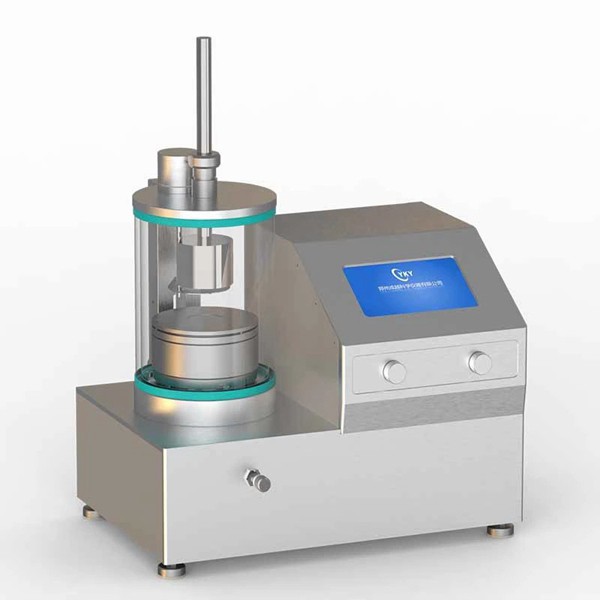

China Supplier Small 150W DC Power Supply Magnetron Sputter Coater

Product description

With the continuous development of materials science, vacuum technology, electronic technology and other fields, sputtering coating technology is also constantly innovating and improving. In the future, sputtering coating machines will pay more attention to technological innovation in improving coating quality, reducing production costs, and improving production efficiency. With the continuous development and improvement of sputtering coating technology, its application fields will also continue to expand. In the future, sputtering coating machines will be more widely used in emerging fields such as new energy, environmental protection, and biomedicine, providing strong support for the development of these fields.

Sputtering coating machines are commonly used in the manufacturing of semiconductor devices, such as integrated circuits, solar cells, etc., to prepare thin films with conductive, insulating, protective and other functions through sputtering coating technology. The application of sputtering coating machines in the aerospace field is mainly reflected in the preparation of high-performance coating materials, such as wear-resistant, corrosion-resistant, high-temperature resistant coatings, to improve the performance and lifespan of aerospace vehicles.

Sputtering coating machines are widely used in fields such as optics, electronics, aerospace, medical devices, etc., mainly for preparing functional thin film materials. Sputtering coating machines are widely used in the coating manufacturing of optical equipment such as glasses, optical lenses, and photography lenses, to increase optical performance such as anti reflection, anti reflection, and reflectivity.

Sputtering coating machine is a surface treatment equipment based on the phenomenon of sputtering. Sputtering refers to the process in which atoms or molecules on the surface of a solid target material detach and deposit onto the substrate surface under the bombardment of high-energy particles (such as ions, electrons, etc.). The sputtering coating machine uses inert gas (such as argon) or oxygen as the working gas, and uses methods such as arc, ion beam, or magnetic field to heat and excite the surface atoms of the target material, causing them to detach and deposit on the substrate surface, forming the required functional thin film.

Recommended products