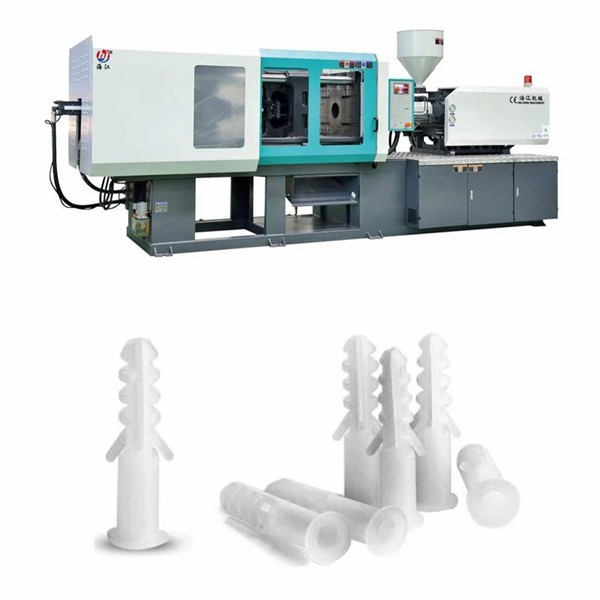

Wholesale Price Plastic Injection Moulding Machine for Production of Camouflage Color Chairs

Product description

With the increasing awareness of environmental protection and the continuous emergence of new materials, the plastic chair forming machine industry is facing new development opportunities and challenges. In the future, environmental protection, energy conservation, efficiency, and intelligence will become important development directions for plastic chair forming machines. At the same time, with the intensification of market competition and the diversification of consumer demand, plastic chair molding machines will continuously introduce new products and technologies to meet the constantly changing and upgrading market.

The plastic molding machine mainly heats plastic raw materials to melt and fill the mold, then cools and solidifies to form the desired shape of plastic products. As one of the core equipment in the plastic processing industry, plastic molding machines will continue to provide strong support for the widespread application of plastic products. In the future development, we look forward to the continuous innovation and progress of the plastic molding machine industry, creating more value for human society.

operational principle

Heating: Add plastic raw materials into the hopper of the molding machine, and use the heating system to bring the plastic to a molten state.

Melting: Plastic in the molten state is pushed into the mold through devices such as screws or plungers.

Forming: In a mold, molten plastic is subjected to pressure to fill the mold cavity, forming the desired shape of the plastic product.

Cooling: After a period of cooling, the molten plastic gradually solidifies, forming solid plastic products.

Remove: After the plastic product has completely cooled down, open the mold and remove the finished product.

Plastic products have penetrated into every aspect of our lives, from daily necessities to high-tech products, all of which cannot be separated from the widespread application of plastics. The importance of plastic molding machines, as the key equipment for manufacturing these plastic products, is self-evident. This article will provide a detailed introduction to the principle, classification, operation methods, and market development trends of plastic molding machines.

Recommended products