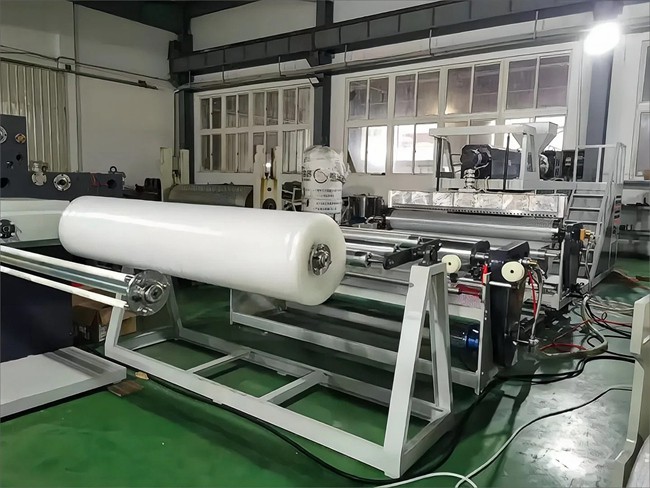

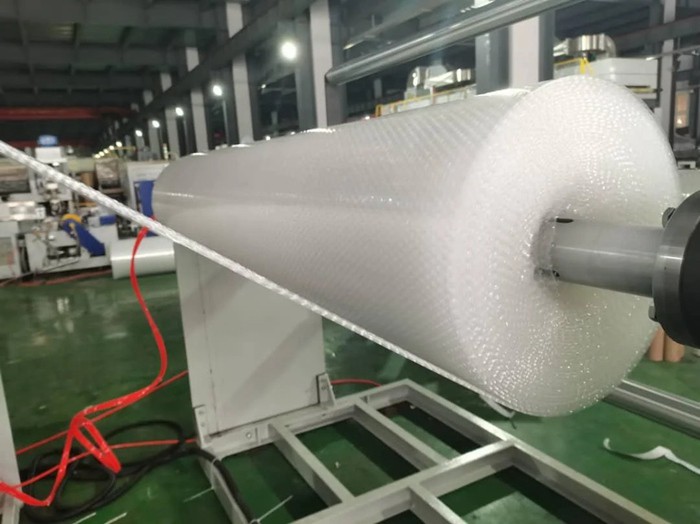

High Quality 3-7 Layers Composite Air Bubble Film Making Machine

Product description

Although the specific operation may vary depending on the model, overall, the operation of the extrusion bubble film machine is relatively simple and easy to use. Bubble wrap plays an important protective role in logistics transportation, preventing collisions and damage to goods during transportation. In the packaging of electronic products, bubble wrap can effectively protect the outer shell and internal components of the product, preventing damage caused by vibration or impact. Furniture products also require bubble wrap for packaging protection during transportation and storage to prevent scratching and damage.

Extrusion bubble film machine is a specialized equipment that uses extrusion and stretching methods to produce bubble film. The core part of the machine is the extruder, which deforms polymer materials (such as polyethylene) by squeezing them to produce the raw material for bubble wrap. The extruder consists of a melting system, a filtering system, an extrusion system, and a regulating system. The melting system heats and melts plastic particles, the filtering system removes impurities and defective materials, the extrusion system applies pressure to the molten material, and the regulating system controls parameters such as temperature, pressure, and speed. The melted polymer material is then fed into the bubble mold through a nozzle for bubble forming operation.

Recommended products