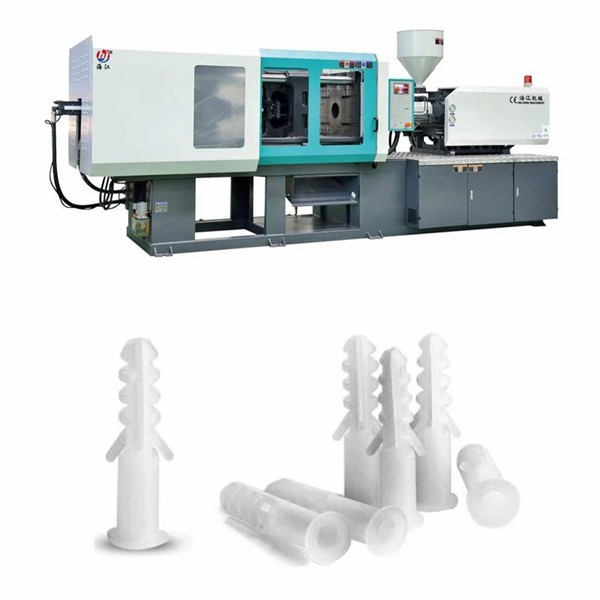

Wholesale Price Preform Injection Moulding Machine Big Size Plastic Injection Molding Machine

Product description

The plastic chair molding machine is one of the key equipment for manufacturing plastic chairs, which processes plastic raw materials into the desired shape and size through specific working principles and technical means. With the continuous progress of technology and changes in market demand, plastic chair molding machines will continue to develop towards efficiency, environmental protection, and intelligence.

Operating a plastic chair molding machine requires certain professional skills and experience, including adjusting machine parameters, controlling heating temperature, selecting appropriate molds, etc. Forming machines have the characteristics of high efficiency, precision, and high degree of automation, which can greatly improve production efficiency and product quality. Meanwhile, with the continuous progress and innovation of technology, plastic chair molding machines are developing towards intelligence, networking, and environmental protection.

Plastic injection molding machines inject molten plastic into molds through injection devices, suitable for producing various complex shaped plastic products. A plastic extrusion molding machine extrudes molten plastic through an extrusion device to form continuous plastic products, such as pipes, bars, etc. Plastic blow molding machines use compressed air to blow molten plastic into the desired shape of plastic products, suitable for producing hollow plastic products. Compressors and transfer molding machines are mainly used for the molding of thermosetting plastics, which solidify the plastic in the mold by applying pressure.

operational principle

Heating: Add plastic raw materials into the hopper of the molding machine, and use the heating system to bring the plastic to a molten state.

Melting: Plastic in the molten state is pushed into the mold through devices such as screws or plungers.

Forming: In a mold, molten plastic is subjected to pressure to fill the mold cavity, forming the desired shape of the plastic product.

Cooling: After a period of cooling, the molten plastic gradually solidifies, forming solid plastic products.

Remove: After the plastic product has completely cooled down, open the mold and remove the finished product.

Plastic products have penetrated into every aspect of our lives, from daily necessities to high-tech products, all of which cannot be separated from the widespread application of plastics. The importance of plastic molding machines, as the key equipment for manufacturing these plastic products, is self-evident. This article will provide a detailed introduction to the principle, classification, operation methods, and market development trends of plastic molding machines.

Recommended products