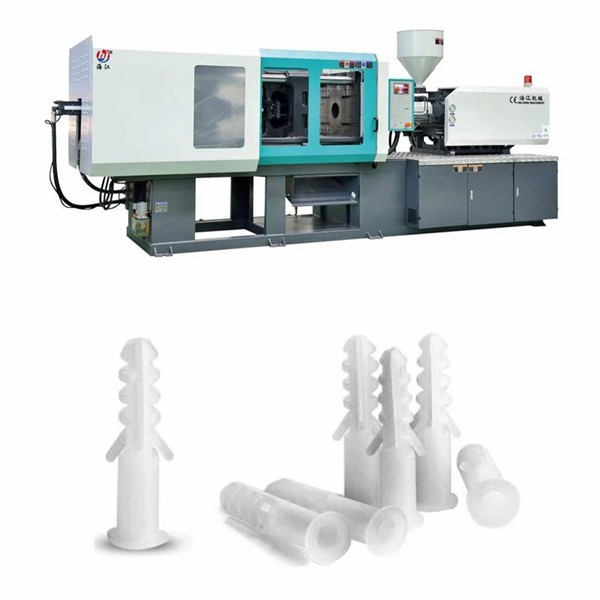

New-Style Hot Sale Plastic Chair Injection Moulding Machine Big Size Plastic Injection Molding Machine

Product description

The melt is fed into the mold through the injection or compression system of the molding machine. In the mold, the melt is subjected to pressure, filling the mold cavity and forming the shape of a plastic chair. After a period of cooling and solidification, the melt transforms into a solid plastic chair. Finally, open the mold and take out the formed plastic chair.

The plastic molding machine mainly heats plastic raw materials to melt and fill the mold, then cools and solidifies to form the desired shape of plastic products. As one of the core equipment in the plastic processing industry, plastic molding machines will continue to provide strong support for the widespread application of plastic products. In the future development, we look forward to the continuous innovation and progress of the plastic molding machine industry, creating more value for human society.

Adjust the pressure of the machine according to the molding needs to adapt to the required molding pressure. Start the machine and start the molding process. Under the action of heating and pressure, the raw materials gradually melt and flow, filling the mold cavity. After the plastic parts to be formed have cooled down, turn off the heating element to allow them to cool and solidify. After cooling the formed plastic parts, open the mold and take out the finished product. Check if the finished product meets the requirements, clean the mold and machine, and proceed to the next round of molding preparation.

Plastic injection molding machines inject molten plastic into molds through injection devices, suitable for producing various complex shaped plastic products. A plastic extrusion molding machine extrudes molten plastic through an extrusion device to form continuous plastic products, such as pipes, bars, etc. Plastic blow molding machines use compressed air to blow molten plastic into the desired shape of plastic products, suitable for producing hollow plastic products. Compressors and transfer molding machines are mainly used for the molding of thermosetting plastics, which solidify the plastic in the mold by applying pressure.

Recommended products