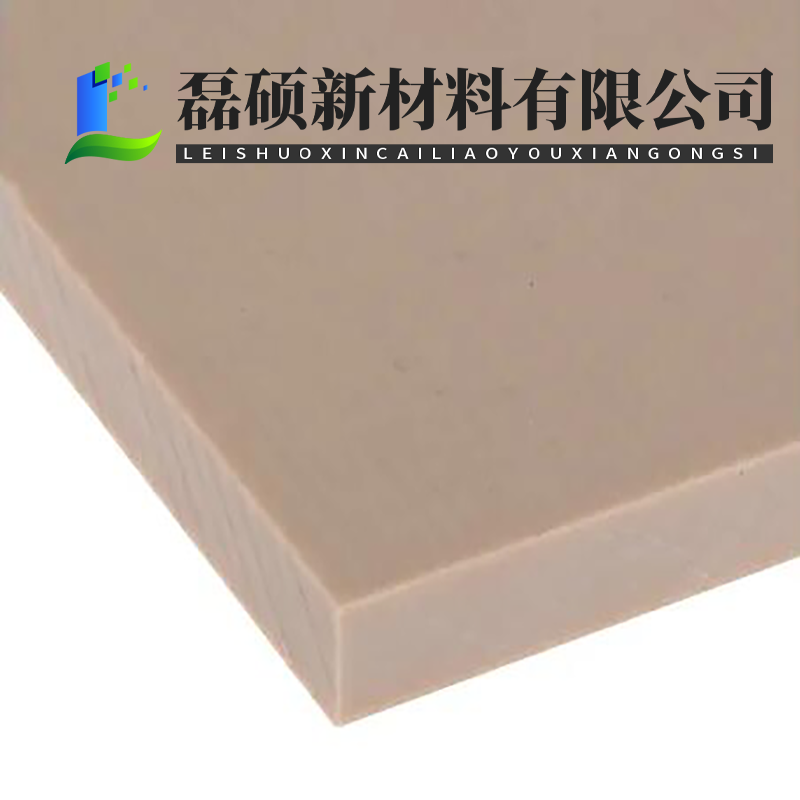

PPSU board vacuum molded products

Product description

PPSU board vacuum forming is a process of processing PPSU (polyphenylsulfone) boards into specific shaped products.

The basic process is as follows:

Board preparation: Select PPSU boards with appropriate thickness and specifications.

Heating softening: Place the board in the heating equipment to soften it uniformly.

Adsorption molding: Quickly place the softened sheet metal on the mold, and through vacuum adsorption or positive pressure gas, make the sheet metal adhere to the shape of the mold, forming the desired product contour.

Cooling and shaping: The formed product is cooled to solidify and stabilize its shape.

Demolding and trimming: After cooling is completed, the product is removed from the mold and necessary trimming and edge treatment are carried out.

The advantages of PPSU sheet metal vacuum forming include: the ability to manufacture products with complex shapes; Relatively high production efficiency; The product has good chemical corrosion resistance, high temperature resistance, and mechanical properties.

This molding process is commonly used in medical equipment, food processing, electronics and other fields, such as manufacturing medical device components, food containers, electrical casings, etc.

Recommended products