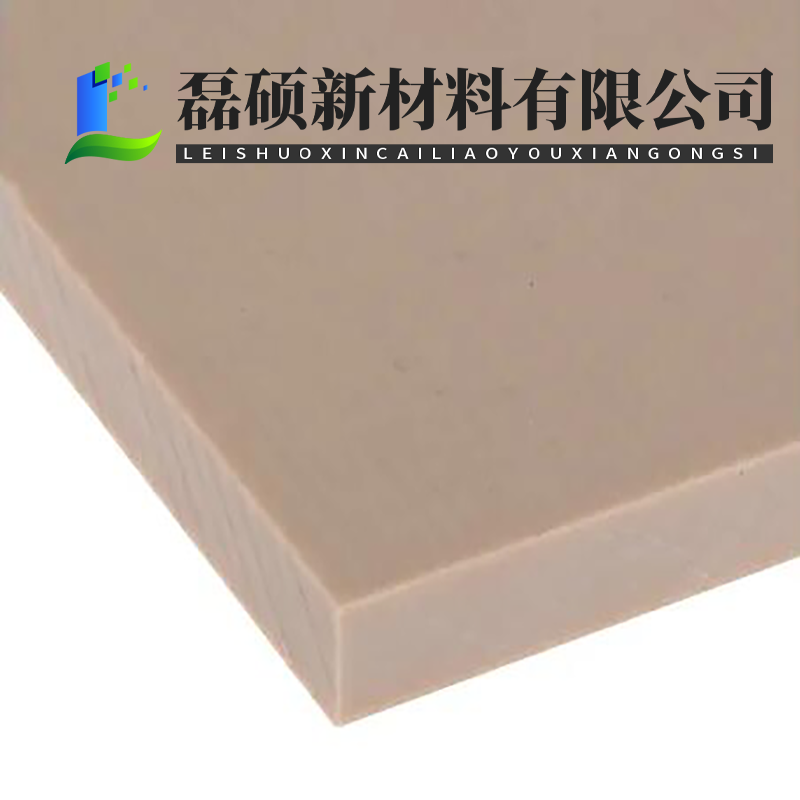

PPSU (polyphenylsulfone) American Solvay Radel R-5000

Product description

PPSU (polyphenylsulfone) is a transparent polyphenylsulfone material with various excellent properties. The following are some of its characteristics and main application areas:

characteristic:

Has ultra-high toughness and good dimensional stability.

Can withstand high temperatures, with a hot deformation temperature of up to 207 ° C (405 ° F).

It has excellent long-term hydrolysis stability and performs ideal in hot water fittings and medical devices that require repeated steam disinfection.

It has good chemical resistance and is superior to PSU (polysulfone) and PEI (polyetherimide).

Can withstand over 1000 steam sterilization cycles without significant loss of characteristics.

Inherent flame retardancy, with good electrical performance and good resistance to thermal aging.

Colorable and radioactive, it can be used for electron beam disinfection, radiation disinfection, ethylene oxide disinfection, etc.

Usage:

Medical field: can be used to manufacture disinfection boxes, disinfection discs, dental and surgical instruments, medical equipment, etc. For example, surgical tool trays, heart valves, pacemakers, gas masks, dental braces, etc. have good biocompatibility, hydrolysis resistance, acid resistance, alkali resistance, and other characteristics, making them suitable for the requirements of medical environments.

Food service field: can be used for food service pallets, etc.

Automotive field: It also has applications in the automotive field.

In the aerospace field, it can be used for aircraft interiors and complies with strict FAA regulations on low heat release, low smoke generation, and low toxic gas emissions.

Other: It can also be used to manufacture pipeline device manifolds, as well as electronic and electrical components, lighting fixtures, household appliance components, etc.

The price may vary depending on factors such as region, supplier, and procurement volume. If you want to know the specific price, it is recommended to contact the relevant supplier for consultation.

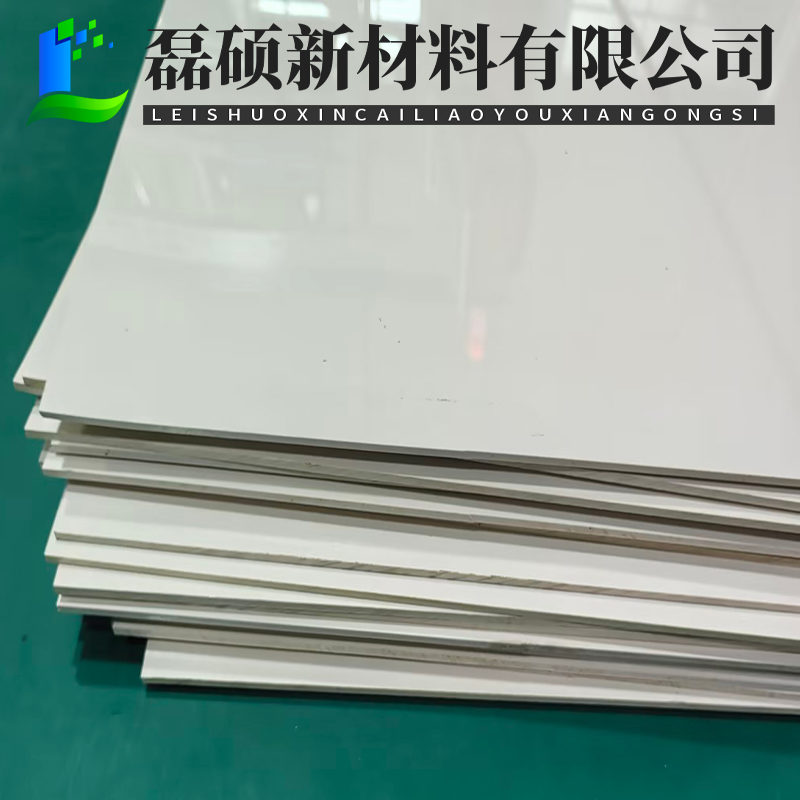

In terms of processing, the Radel R-5000 can adopt various methods, such as film extrusion, blow molding, machine processing, extrusion sheet, extrusion molding, hot forming, profile extrusion molding, injection molding, etc. However, during processing, it is necessary to melt and shape at high temperatures, while ensuring minimal temperature fluctuations during the processing, and using specialized screws and molds to ensure processing quality and efficiency.

Recommended products