Factory Outlet Household Products Plastic Chair Injection Moulding Molding Machine

Product description

With the increasing awareness of environmental protection and the continuous emergence of new materials, the plastic chair forming machine industry is facing new development opportunities and challenges. In the future, environmental protection, energy conservation, efficiency, and intelligence will become important development directions for plastic chair forming machines. At the same time, with the intensification of market competition and the diversification of consumer demand, plastic chair molding machines will continuously introduce new products and technologies to meet the constantly changing and upgrading market.

Operating a plastic chair molding machine requires certain professional skills and experience, including adjusting machine parameters, controlling heating temperature, selecting appropriate molds, etc. Forming machines have the characteristics of high efficiency, precision, and high degree of automation, which can greatly improve production efficiency and product quality. Meanwhile, with the continuous progress and innovation of technology, plastic chair molding machines are developing towards intelligence, networking, and environmental protection.

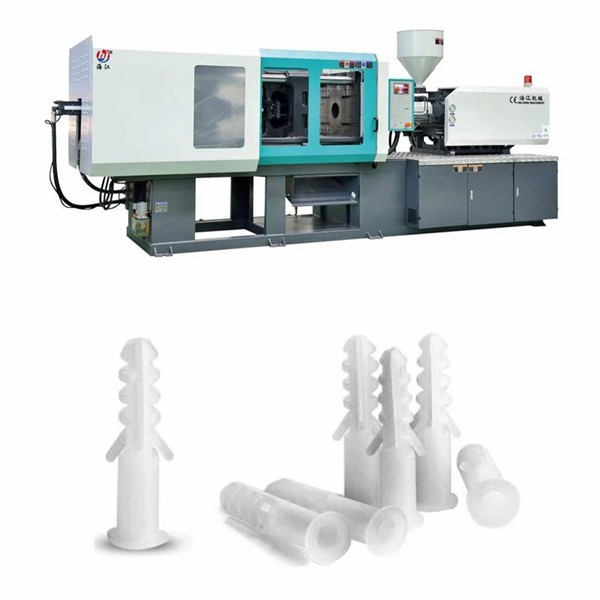

Plastic chair molding machines can be classified according to different molding principles and technical characteristics, such as injection molding machines, compression molding machines, etc. Among them, injection molding machine is a commonly used type in the manufacturing of plastic chairs. It uses high-pressure injection to inject melted plastic materials into the mold, suitable for producing plastic chairs with complex shapes and precise dimensions.

Plastic chair molding machine is a specialized mechanical equipment used for manufacturing plastic chairs. Plastic chair molding machine is a mechanical equipment that processes plastic raw materials into the shape required for plastic chairs. It heats plastic raw materials to a molten state, then injects or presses them into a mold, undergoes a cooling and curing process, and forms the final plastic chair product.

Plastic injection molding machines inject molten plastic into molds through injection devices, suitable for producing various complex shaped plastic products. A plastic extrusion molding machine extrudes molten plastic through an extrusion device to form continuous plastic products, such as pipes, bars, etc. Plastic blow molding machines use compressed air to blow molten plastic into the desired shape of plastic products, suitable for producing hollow plastic products. Compressors and transfer molding machines are mainly used for the molding of thermosetting plastics, which solidify the plastic in the mold by applying pressure.

Recommended products