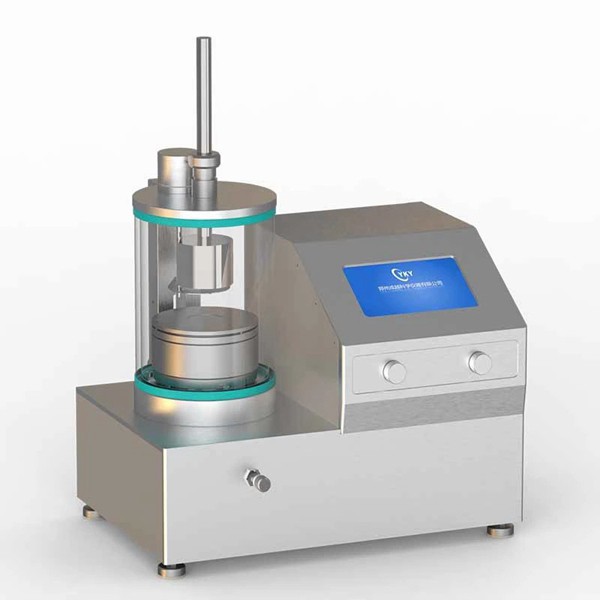

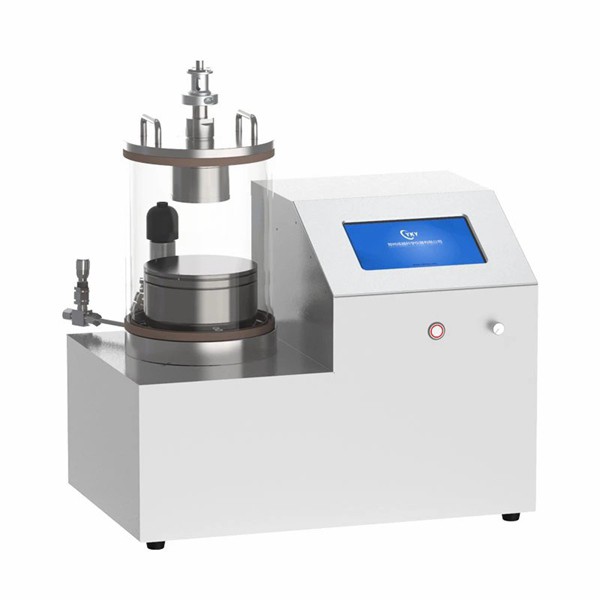

Wholesale Price Triple Targets Magnetron Sputter Coater with DC and RF Power Supply for Multilayer Films

Product description

Each type of coating machine has its specific working principle and application field. For example, a physical vapor coating machine utilizes energy such as electric arcs and high frequencies to evaporate or ionize metal and deposit it onto the substrate; The sputtering coating machine uses an arc beam, electron beam, or ion beam to peel off the metal target material and form a thin film.

The basic components include a vacuum system, sedimentation chamber, power supply, and control system. The vacuum system is used to create a vacuum, and the deposition chamber is the main area for depositing thin films. The power supply controls parameters such as material deposition speed and temperature, and the control system ensures that the deposition thickness, uniformity, and quality of the thin film meet the requirements. According to different processes, requirements, and applications, coating machines can be divided into various types, such as physical vapor coating machines, chemical vapor coating machines, ion coating machines, magnetron coating machines, sputtering coating machines, etc.

A coating machine is a device that deposits film materials onto the surface of a substrate to form a thin film, with various types and application fields. Its working principle and process characteristics ensure the high quality, precision, and wide application of the coating. A coating machine is a device specifically designed to deposit various film materials onto the surface of substrates. By using methods such as vacuum or chemical reactions, solid materials are transformed into gaseous materials, which are then deposited on the substrate surface to form a thin film.

With the continuous development of materials science, vacuum technology, electronic technology and other fields, sputtering coating technology is also constantly innovating and improving. In the future, sputtering coating machines will pay more attention to technological innovation in improving coating quality, reducing production costs, and improving production efficiency. With the continuous development and improvement of sputtering coating technology, its application fields will also continue to expand. In the future, sputtering coating machines will be more widely used in emerging fields such as new energy, environmental protection, and biomedicine, providing strong support for the development of these fields.

Sputtering coating machine is a surface treatment equipment based on the phenomenon of sputtering. Sputtering refers to the process in which atoms or molecules on the surface of a solid target material detach and deposit onto the substrate surface under the bombardment of high-energy particles (such as ions, electrons, etc.). The sputtering coating machine uses inert gas (such as argon) or oxygen as the working gas, and uses methods such as arc, ion beam, or magnetic field to heat and excite the surface atoms of the target material, causing them to detach and deposit on the substrate surface, forming the required functional thin film.

Recommended products