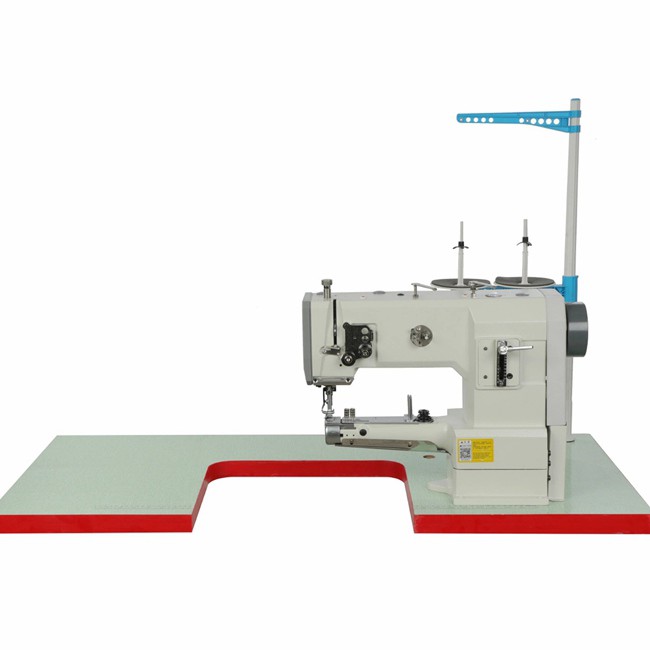

Wholesale Computerized Lockstitch Sewing Machine

Product description

In today's industrialization, industrial sewing machines have become an indispensable production tool in the textile and garment industry. They not only improve production efficiency and reduce production costs, but also promote the diversification and personalized development of product design. By flexibly configuring different types of sewing machines, enterprises can easily respond to various complex production demands and market changes, and maintain a competitive advantage.

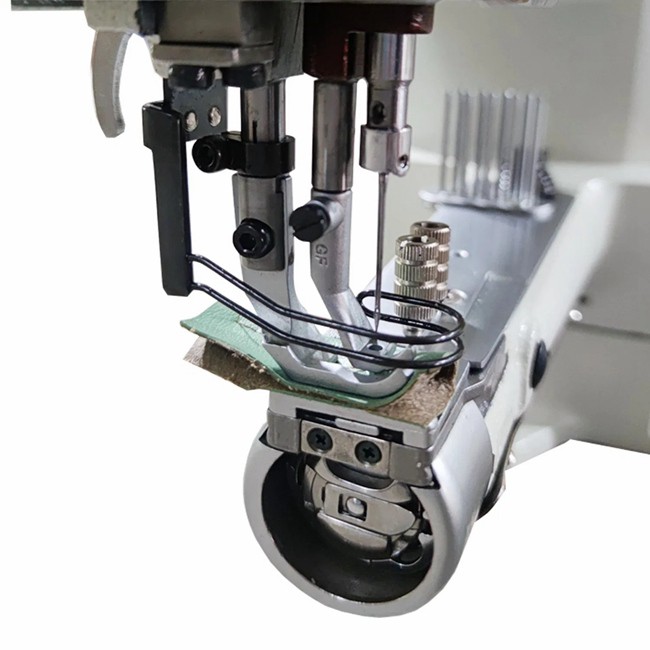

The working principle of a sewing machine mainly includes four steps: thread transfer, pinhole formation, stitch formation, and fabric transfer. The sewing machine provides two threads, upper and lower, through a spool, which enter the machine body through a guide, tensioner, and spool to ensure smooth thread transfer. The sewing machine forms needle holes through the reciprocating motion of the upper and lower needles. When the needle moves downwards, the upper needle passes the thread through the fabric through the thread plate and the lower needle eye plate, forming a needle eye. The formation of a trace depends on the interweaving of online and offline lines. When the upper needle passes down through the fabric, it will thread the upper thread through the fabric and interweave with the lower thread in the needle eye, forming a stitch. The sewing machine transfers fabric through the lower hem, upper hem, and gear transmission. When the gear rotates, the lower swing and upper swing move alternately, conveying the fabric forward.

Recommended products