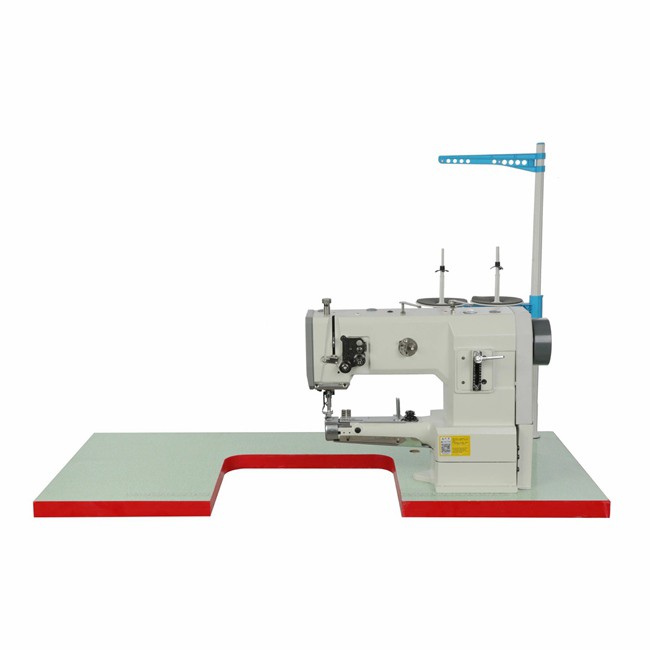

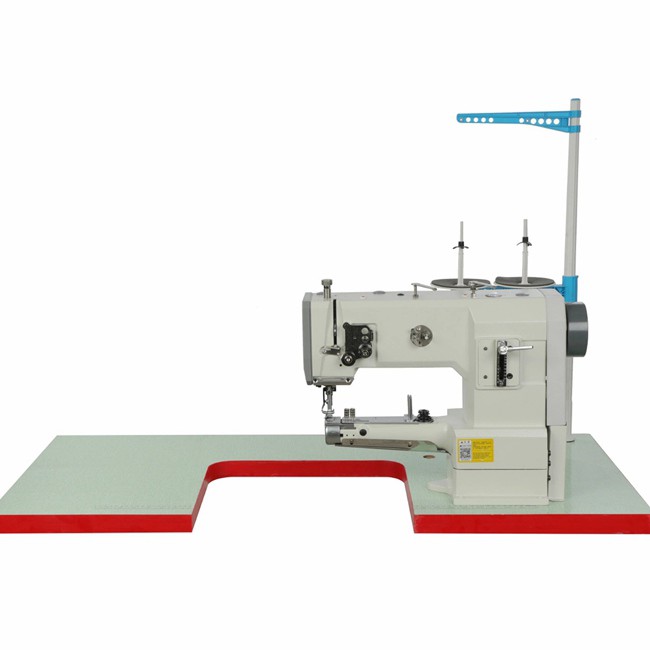

Factory Supplier Computer Simple Direct Drive Single Needle Lockstitch Sewing Machine

Product description

Computerized sewing machines are widely used in various industries such as clothing, footwear, luggage, furniture, and automotive interiors. For enterprises engaged in mass production, the high speed and efficiency of computerized sewing machines can significantly improve production efficiency and reduce production costs. At the same time, its high precision and versatility also make computerized sewing machines widely applicable in the fields of personalized customization and high-quality sewing products.

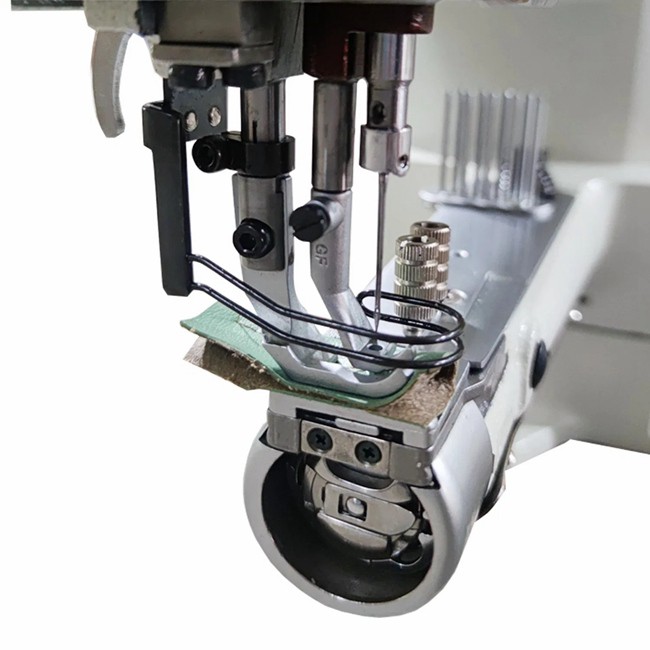

Computer controlled sewing machine, also known as computerized sewing machine, is an important achievement of modern sewing technology. Computerized sewing machine adopts computer precision control, which can achieve high-precision sewing operations, uniform and beautiful sewing lines, and excellent sewing effects. This is particularly important for industries that require high-quality sewing products. The computer sewing machine can automatically complete the set sewing work, including automatic edge sewing, automatic adjustment of thickness and seam tension, automatic speed change, automatic torque change, automatic thread cutting, automatic needle patching, etc. These functions greatly reduce the labor intensity of operators and improve production efficiency.

Industrial sewing machines have also promoted the upgrading and transformation of the entire industry chain. With the popularization and application of automation and intelligent technology, the textile and garment industry is gradually developing towards digitalization, networking, and intelligence, injecting new vitality into the sustainable development of the industry. As the core production equipment in the textile and garment industry, industrial sewing machines play an important role in promoting industry progress and upgrading. With the continuous advancement of technology and changing market demands, we have reason to believe that industrial sewing machines will play a more important role and contribute in the future.

At present, by introducing automation control systems and artificial intelligence technology, industrial sewing machines can achieve a higher degree of automation and intelligent production, reduce manual intervention, and improve production efficiency and product quality. Digital technology enables sewing machines to precisely control sewing parameters, ensuring product consistency and stability; Network technology enables remote monitoring and maintenance, improving the convenience and flexibility of production management. Modern industrial sewing machines pay more attention to energy conservation and environmental protection in their design, using low-energy motors, optimizing mechanical structures, and other methods to reduce energy consumption and noise pollution, while reducing negative impacts on the environment.

Recommended products