High-Quality Double Line Plastic Roll Garbage Bag Making Machine

Product description

The cut garbage bags need to be punched and sealed. Advanced robotic punching equipment creates easy-to-use pockets on garbage bags based on design and requirements. Subsequently, efficient machines seal the bottom of the bag to prevent garbage from leaking out. After sealing, the garbage bag is checked by testing equipment to see if it meets the standards. Qualified garbage bags are sent to the packaging machine for centralized packaging, and finally sealed in smooth plastic bags with relevant labels printed, ready for sale.

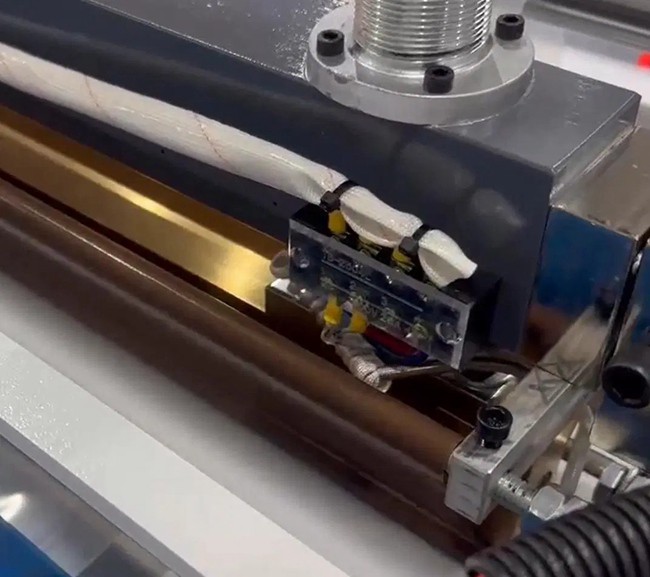

The heat sealing cutter is one of the core components of the garbage bag manufacturing machine, which precisely controls the temperature through a thermostat to seal and cut the plastic film. The whole bag device is responsible for processing the entire bag after producing a fixed number of bags, ensuring the consistency and stability of the product. The temperature controller adopts Delta DTA4848R with self-tuning function, with temperature error controlled within 0.1 degrees, ensuring precise sealing and cutting quality. The main raw material for producing garbage bags is polyethylene particles. These particles are formulated from high molecular weight polymers such as high-density polyethylene or low-density polyethylene, as well as other auxiliary materials such as fillers, plasticizers, lubricants, stabilizers, colorants, etc. These materials are mixed in specific proportions to ensure the overall performance of the garbage bag is good.

Garbage bag manufacturing machine is a production equipment that integrates automation and efficiency. It mainly consists of a material storage device, a stepper device, a frequency conversion device, a whole bag device, a heat sealing cutter, and a control device. These components work together to complete the entire process from raw material transportation to finished product production. The garbage bag manufacturing machine also pays attention to energy conservation and emission reduction in the production process. By optimizing equipment structure and improving production efficiency, reducing energy consumption and waste emissions, we contribute to the cause of environmental protection.

With the acceleration of urbanization, garbage disposal has become an important part of urban management. Garbage bags, as an indispensable item in daily life, are receiving increasing attention for their production efficiency and environmental performance. As an important equipment in this field, the garbage bag manufacturing machine not only improves production efficiency, but also continuously promotes the development of environmentally friendly production through technological innovation.

Recommended products