Best Price Garbage Carry Plastic Bag Making Machine for Sale

Product description

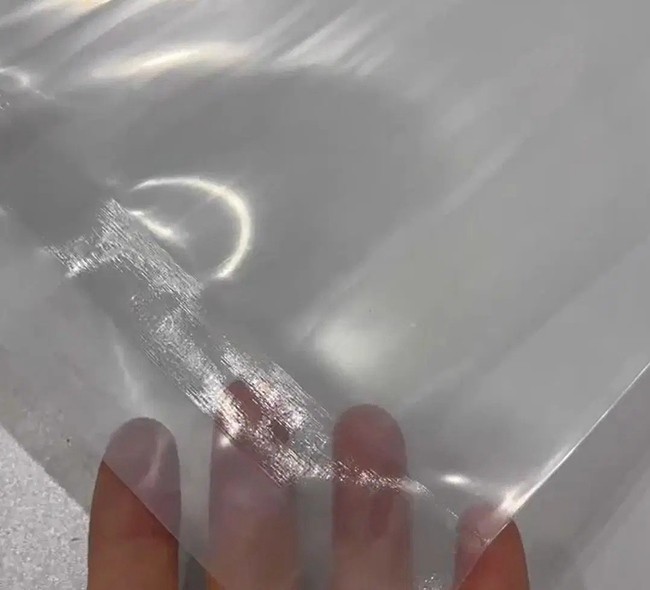

If the product design has printing content, the printing process should be carried out before the plastic film cools down. After printing is completed, the plastic film is rolled into large rolls and then cut by a bag making machine. The bag making machine divides the roll plastic film into individual garbage bag products according to the set length and shape. Different product forms (such as flat rolled bags, vest style rolled bags, etc.) have different cutting methods.

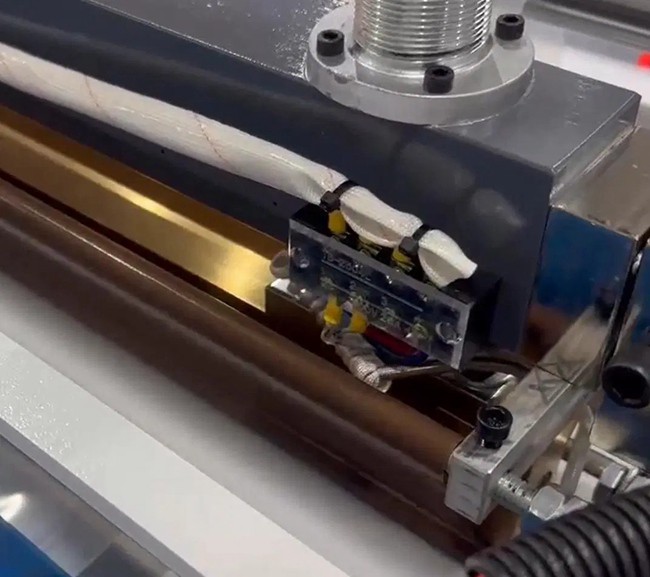

The heat sealing cutter is one of the core components of the garbage bag manufacturing machine, which precisely controls the temperature through a thermostat to seal and cut the plastic film. The whole bag device is responsible for processing the entire bag after producing a fixed number of bags, ensuring the consistency and stability of the product. The temperature controller adopts Delta DTA4848R with self-tuning function, with temperature error controlled within 0.1 degrees, ensuring precise sealing and cutting quality. The main raw material for producing garbage bags is polyethylene particles. These particles are formulated from high molecular weight polymers such as high-density polyethylene or low-density polyethylene, as well as other auxiliary materials such as fillers, plasticizers, lubricants, stabilizers, colorants, etc. These materials are mixed in specific proportions to ensure the overall performance of the garbage bag is good.

Recommended products