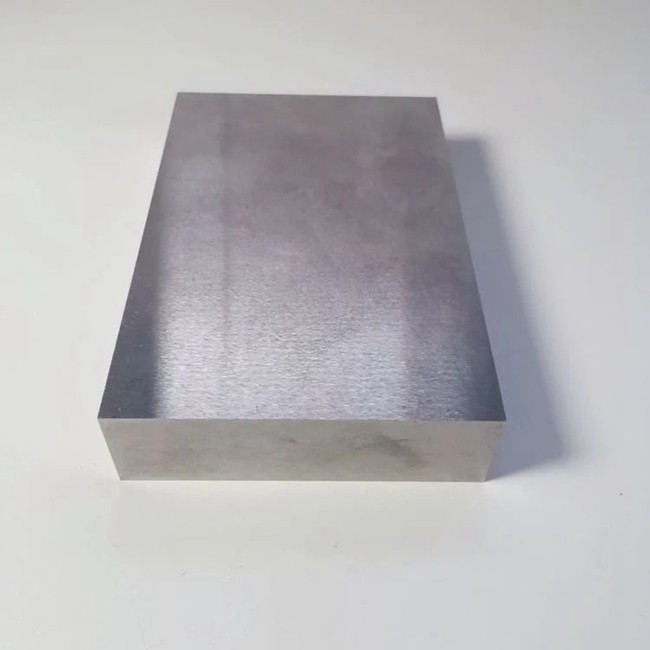

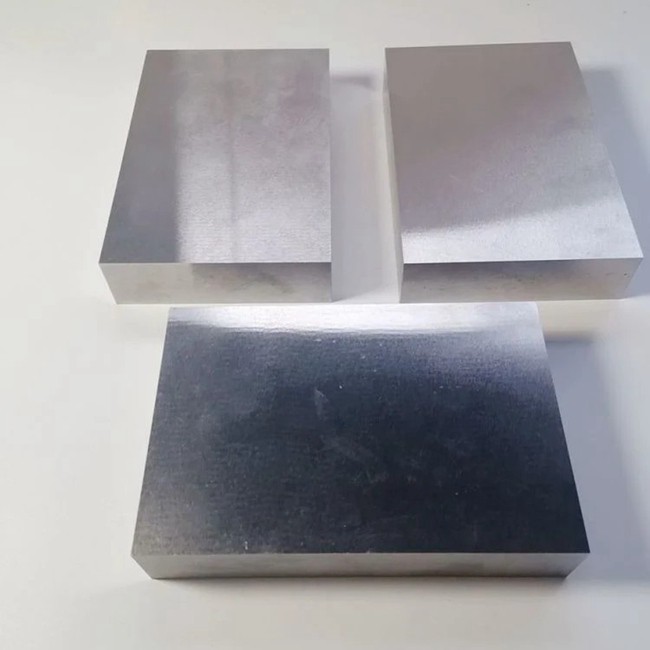

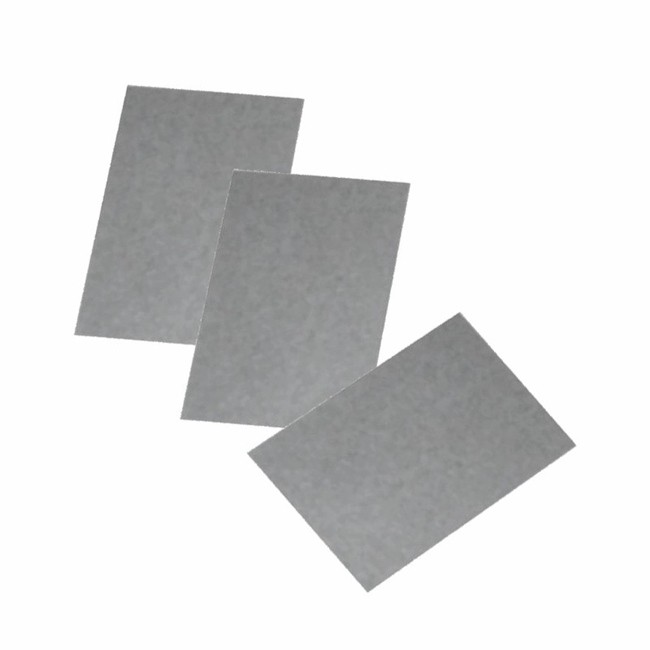

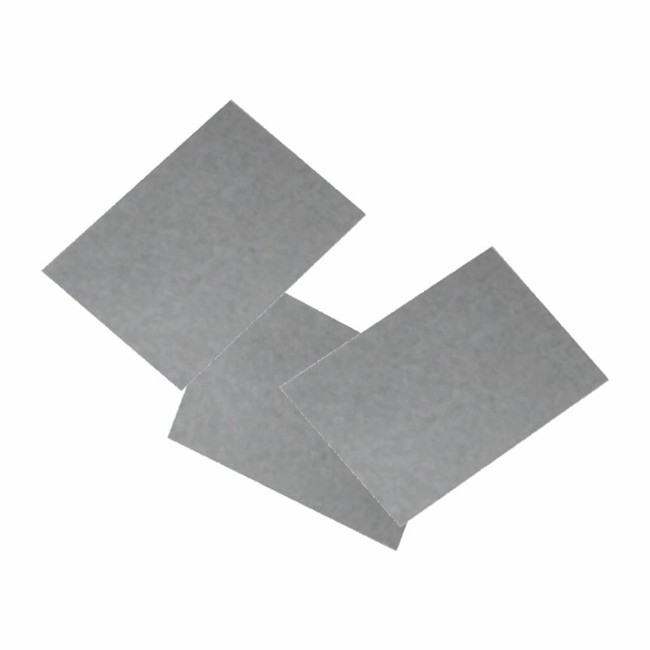

100% Virgin Material Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Mold Making

Product description

Tungsten alloy plate is a kind of composite plate synthesized from tungsten and other metals (e.g. nickel, iron, copper, etc.) through a special process. With its unique physical and chemical properties, this alloy has shown great application value in many fields. Tungsten alloy plates are known for their extremely high density, which gives them excellent weight-carrying capacity and compression resistance. This high density property makes tungsten alloy sheet perform well in applications that require high weight or high density materials, such as armor-piercing bullets in the military and counterweights for sports equipment.

In the field of sports, tungsten alloy plate also plays an important role. For example, the main body of professional darts is made of tungsten alloy plate, and the counterweight part of golf head is also often made of tungsten alloy to improve the hitting effect. Tungsten alloy plate also plays an important role in the field of machining and mold making due to its excellent mechanical properties and processing performance. Its high hardness and wear resistance make it an ideal material for making high-precision molds and machining complex-shaped parts.

The density of tungsten alloy plate is extremely high, generally between 16.5~19.0g/cm³, which is equivalent to more than twice the density of steel. This characteristic gives it excellent tensile strength and compression resistance. The tensile strength of W-Ni-Fe high-density alloy in sintered state can be up to 800~1000MPa, and the strength can be further increased to 1300~1500MPa after heat treatment and deformation processing.

The production of tungsten alloy plate is a complex and delicate process, which mainly includes several steps such as powder making, mixing, pressing and sintering. First of all, according to the specific use, select and proportion appropriate tungsten carbide powder and cobalt (Co) and other additives, and prepare a homogeneous mixture through the steps of wet grinding, mixing, crushing, drying and sieving. Subsequently, the molding agent is added for drying and sieving again to make a mixture that meets the requirements. After that, the mixture is pressed into the required shape by pressing process, and then the material is densified by sintering process to form tungsten alloy plate blanks. Finally, the quality of the product is ensured by flaw inspection, and finally packaged into the warehouse.

As an indispensable high-performance material in modern industry, it shows excellent application value in many fields by virtue of its unique physical and chemical properties. As a high-performance material, tungsten alloy plate shows wide application prospects and great market potential in modern industry. With the continuous development of science and technology and the continuous improvement of process, the performance of tungsten alloy plate will be further improved, and its application fields will be more extensive.

Recommended products