Wholesale 316 Marine Grade Stainless Steel 3-Way Pipe Tee Elbow

Product description

The manufacturing process of stainless steel tee bends mainly includes hydraulic bulging and hot pressing forming. Among them, the hydraulic bulging process uses a dedicated hydraulic press to inject liquid into a tube blank with a diameter equal to that of a tee, and synchronously squeezes the tube blank through the two horizontal side cylinders of the hydraulic press, causing the metal material to flow in the mold cavity and bulge out the branch pipe. This process has high production efficiency and increases the thickness of the main pipe and shoulder wall, but requires a large tonnage of equipment, mainly suitable for the manufacture of standard wall thickness stainless steel tees.

Stainless steel three-way bend pipes are used in indoor and outdoor building water supply systems due to their superior performance, ensuring water quality safety and reducing pipeline maintenance costs. In the petrochemical industry, stainless steel tee bends are used to connect various pipelines and equipment, ensuring the safety and efficiency of fluid transportation. Stainless steel tee bends are used for branching and merging in oil and gas pipelines, adapting to complex pipeline layouts. Stainless steel tee pipes also play an important role in industries such as electricity, shipbuilding, and papermaking.

The stainless steel material used for the stainless steel three-way bend pipe is smooth inside and outside, non-toxic, and not easy to rust. It has extremely high corrosion resistance and strength, ensuring the long-term stable operation of the pipeline system. Compared to traditional pipe joints, stainless steel tee bends have lower flow resistance and can effectively improve fluid transport efficiency. The three-way bend pipe has a compact design, occupies a small space, and is easy to install and maintain. Adopting advanced connection technologies such as welding and flange connections to ensure sealing performance and eliminate water leakage issues. Stainless steel three-way bend pipes have complete specifications and can be applied to complex environments such as high vacuum and strong pressure, meeting the needs of different fields.

In conclusion, the stainless steel 3-way elbow pipe is a testament to the ingenuity and practicality of modern piping solutions. Its robust construction, versatility, and hygienic properties make it an indispensable tool in the arsenal of engineers and plumbers worldwide. Whether you're designing a new piping system or upgrading an existing one, incorporating stainless steel 3-way elbow pipes is a decision that promises reliability, efficiency, and peace of mind.

One of the primary advantages of using stainless steel for these elbows is its ability to maintain hygiene and prevent contamination. This is particularly important in applications where the purity of the transported medium is critical, such as in food and beverage processing or pharmaceutical manufacturing.

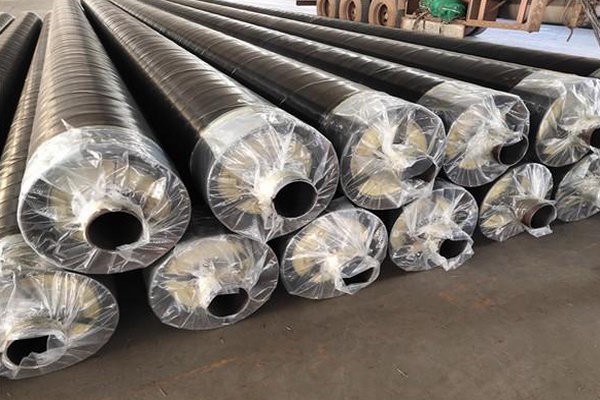

The stainless steel 3-way elbow pipe is manufactured from high-grade stainless steel, which is renowned for its corrosion resistance, durability, and strength. This material ensures that the elbow can withstand extreme temperatures and pressures, as well as exposure to corrosive substances, without compromising its integrity.

Recommended products