Wholesale Printer Digital Printing Machine Blank Brass Dog Tag

Product description

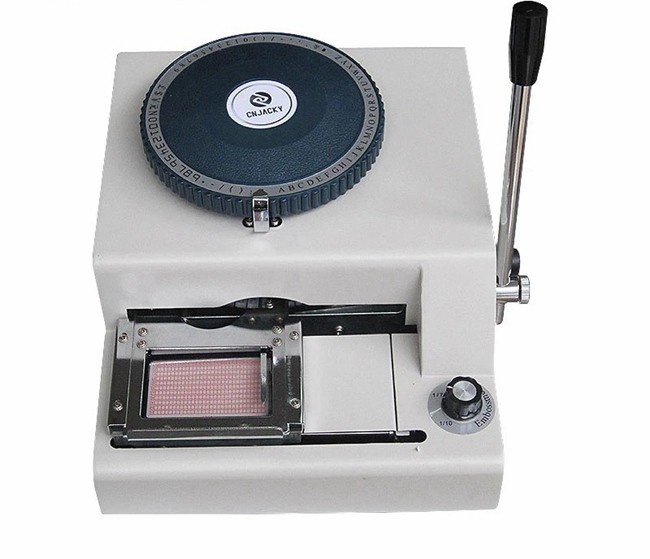

The dog tag embossing machine usually adopts humanized design, the operation interface is simple and easy to understand, users can quickly get started without professional training. At the same time, the machine is also equipped with safety guards and fault alarm system to ensure the safety and stability of the operation process.

The structure of Dog embossing machine is relatively simple and compact, easy to maintain and repair. Users only need to follow the instruction manual to regularly clean and check all parts of the machine to ensure its long-term stable operation.

Dog card embossing machine is usually designed with electric or pneumatic drive, which is able to automate the embossing process and greatly improve the production efficiency. Compared with manual production, it can complete the embossing of a large number of dog tags in a short period of time, reducing the tedious and time-consuming manual operation.

Automated operation not only improves production efficiency, but also significantly reduces production costs. Since the machine can work continuously and does not require frequent breaks, it maximizes the use of time resources and reduces errors and waste caused by improper manual operation or fatigue.

As an amazing tool for creative DIY, card embossing machine plays an important role in the field of handicraft. It can not only bring endless fun and sense of achievement to children, but also stimulate their creativity and imagination. In the future development, with the continuous progress of technology and the increasing demand for personalization, the card embossing machine is expected to occupy a more important position in the DIY market.

Place the material to be embossed on the die, making sure it is centered and flat. If using a hot melt gun for heat embossing, heat the gun to the proper temperature in advance. Place the mold and material together in the embosser, adjust the pressure to the proper level, and gently press the handle of the embosser to emboss. Keep your hand steady during the embossing process and avoid applying too much force to avoid damaging the machine or the material. When pressing is complete, open the embosser and remove the mold and material. Carefully remove the embossed material from the mold and check if the embossing result is satisfactory. If further processing (e.g. hot foil fusing) is required, follow the appropriate steps.

Recommended products