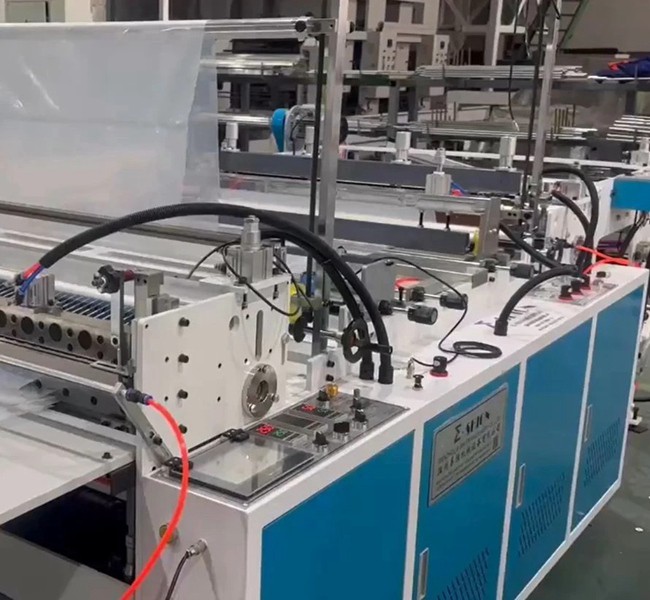

High-Quality Double Line Plastic Roll Garbage Bag Making Machine

Product description

Our factory specializes in producing blown film machines, bag making machines, printing machines, and granulators. Our workshop is equipped with modern technology and a dedicated team of skilled professionals. We take pride in our ongoing commitment to quality and innovation, striving to make our machines meet industry standards. Our workshop is organized in an orderly manner, creating an efficient atmosphere that pays attention to details. We are committed to meeting the needs of our customers and providing them with reliable mechanical solutions.

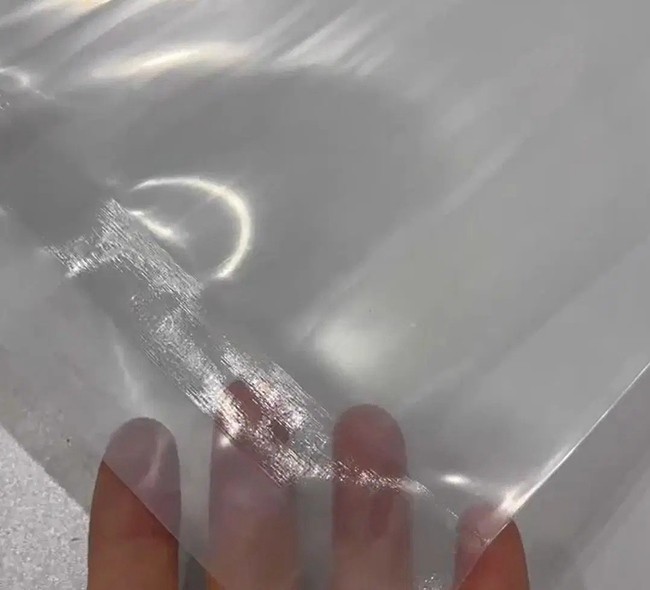

This machine was developed and manufactured by our company based on the integration of advanced foreign technologies. It uses materials such as LDPE, HDPE, and cylindrical film to manufacture garbage bags or folding roll bags.

features:

Used for sealing the bottom of roll type coreless large garbage bags

Double V-shaped folding units make the film smaller

Strong sealing and easy tearing

Equipped with high-pressure gap sensors for more accurate film rupture and bag counting

Automatic rewinding and rewinding

In the machine, polyethylene particles are heated to a molten state and enter the bag making machine through specific pipes. The melted plastic is formed into a continuous plastic film through the blown film process, and when the film width and length meet the design standards, it is cooled and shaped.

The heat sealing cutter is one of the core components of the garbage bag manufacturing machine, which precisely controls the temperature through a thermostat to seal and cut the plastic film. The whole bag device is responsible for processing the entire bag after producing a fixed number of bags, ensuring the consistency and stability of the product. The temperature controller adopts Delta DTA4848R with self-tuning function, with temperature error controlled within 0.1 degrees, ensuring precise sealing and cutting quality. The main raw material for producing garbage bags is polyethylene particles. These particles are formulated from high molecular weight polymers such as high-density polyethylene or low-density polyethylene, as well as other auxiliary materials such as fillers, plasticizers, lubricants, stabilizers, colorants, etc. These materials are mixed in specific proportions to ensure the overall performance of the garbage bag is good.

Recommended products