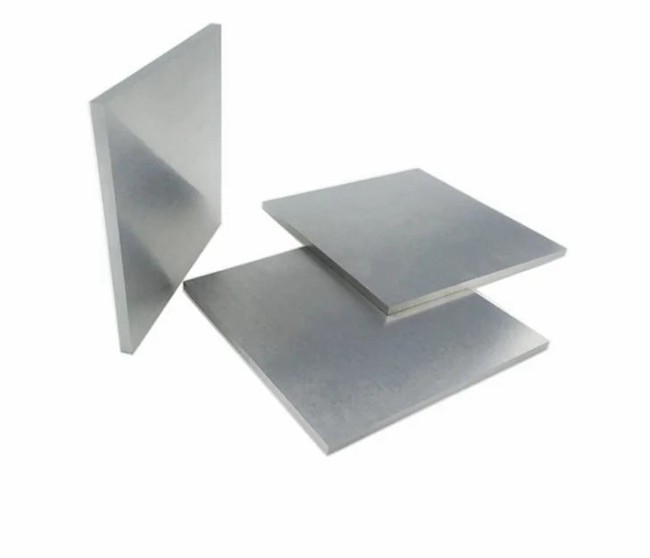

100% Virgin Material Tungsten Carbide Wear Parts Tungsten Carbide Plate for Mold Making

Product description

Tungsten sheet is a type of plate made from tungsten metal with a unique set of physical and chemical properties. Tungsten sheet is a metal material with unique physical and chemical properties that plays an important role in many fields. With the continuous progress of science and technology and the continuous improvement of process, the application fields of tungsten plate will be further expanded and the market demand will continue to grow.

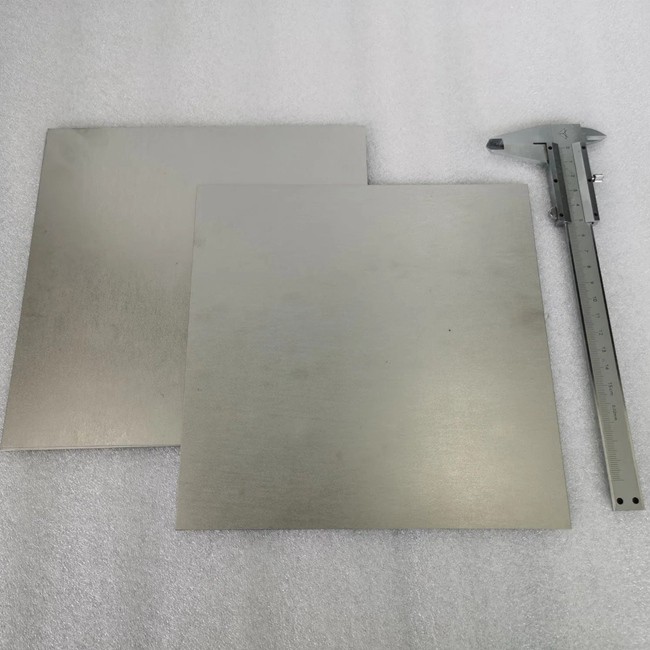

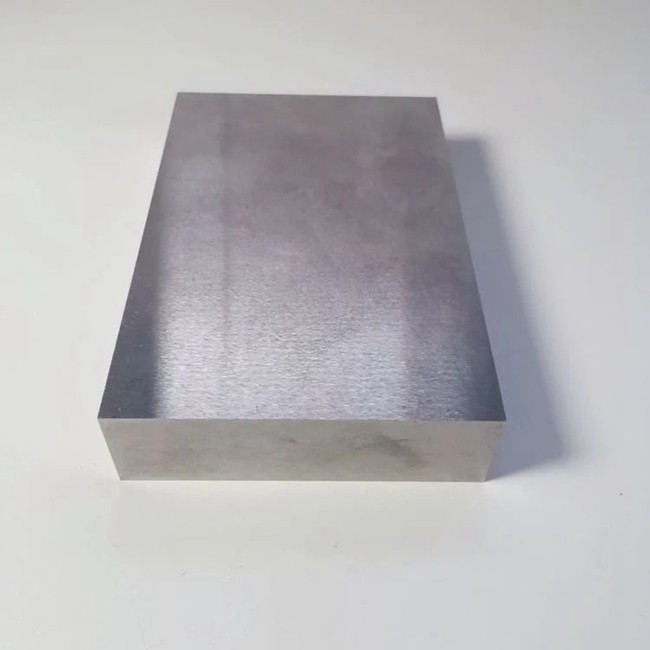

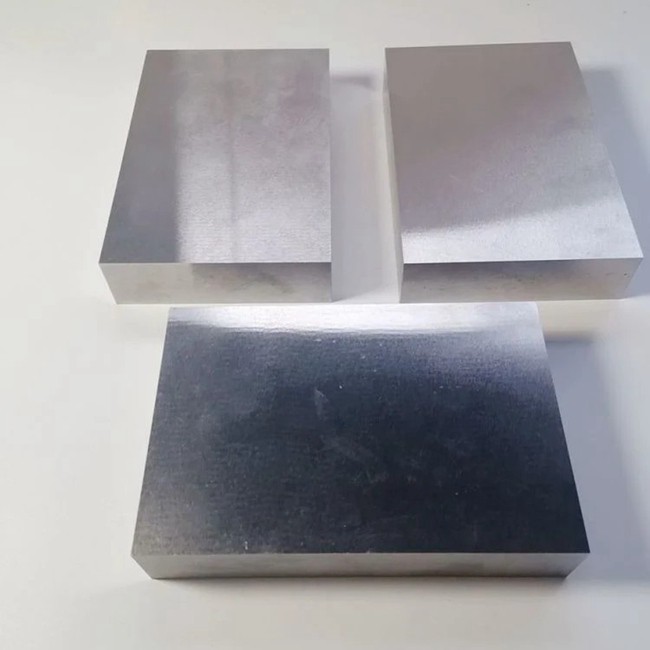

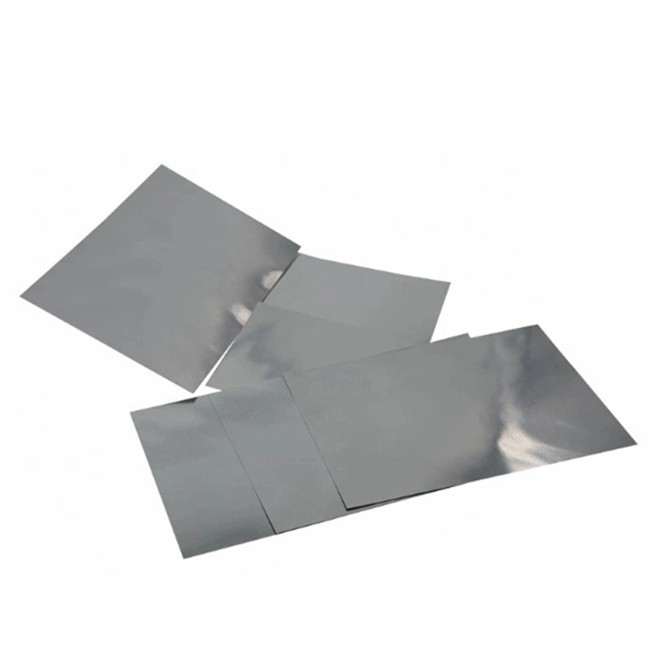

Tungsten plates usually appear steel gray or silver white, with a smooth surface and high hardness. Tungsten is an extremely hard metal, so tungsten sheet inherits this characteristic and has excellent wear resistance and compressive strength. Tungsten has an extremely high melting point of 3422 degrees Celsius, the highest of all metals, which enables tungsten sheet to maintain stable performance in high temperature environments. Tungsten sheet is not subject to air erosion at room temperature and has good corrosion resistance to a wide range of chemicals.

Despite its high hardness, tungsten alloy sheet also has good ductility and plasticity. the elongation of W-Ni-Fe high-density alloy in the sintered state can be up to 10% 15%, and after vacuum or atmosphere dehydrogenation treatment, the elongation can be increased to 20% 30%. This characteristic makes tungsten alloy plate easy to process into various shapes and sizes, which is widely used in the fields of mold making, machining and high-precision instrument manufacturing.

The melting point of tungsten is as high as 3422 degrees Celsius, which is the highest among all metals. As a result, tungsten alloy sheet excels in high-temperature environments and can withstand extreme thermal stability requirements, making it an ideal material for high-temperature applications such as aerospace and nuclear energy. Tungsten alloy sheet is resistant to a wide range of chemicals, including acid and alkali solutions, oxides and salt solutions. Its good chemical stability and corrosion resistance make it widely used in chemical, semiconductor and electronic fields for manufacturing equipment and components with high corrosion resistance requirements.

Recommended products