High-Quality Garbage Carry Plastic Bag Making Machine for Sale

Product description

Our factory specializes in producing blown film machines, bag making machines, printing machines, and granulators. Our workshop is equipped with modern technology and a dedicated team of skilled professionals. We take pride in our ongoing commitment to quality and innovation, striving to make our machines meet industry standards. Our workshop is organized in an orderly manner, creating an efficient atmosphere that pays attention to details. We are committed to meeting the needs of our customers and providing them with reliable mechanical solutions.

As an important equipment for modern environmentally friendly production, the garbage bag manufacturing machine not only improves production efficiency and product quality, but also promotes the development of environmentally friendly production. With the continuous advancement of technology and the improvement of environmental awareness, we believe that garbage bag manufacturing machines will play a more important role in the future, bringing more convenience and beauty to our living environment.

With the increasing awareness of environmental protection, garbage bag manufacturing machines are constantly innovating in technology to reduce their impact on the environment. For example, some manufacturers have started using eco-friendly materials such as non-woven fabrics to replace traditional polyethylene materials and produce more environmentally friendly garbage bags. Non woven garbage bags not only have a longer service life, but can also be recycled, greatly reducing the pressure on the environment.

In the machine, polyethylene particles are heated to a molten state and enter the bag making machine through specific pipes. The melted plastic is formed into a continuous plastic film through the blown film process, and when the film width and length meet the design standards, it is cooled and shaped.

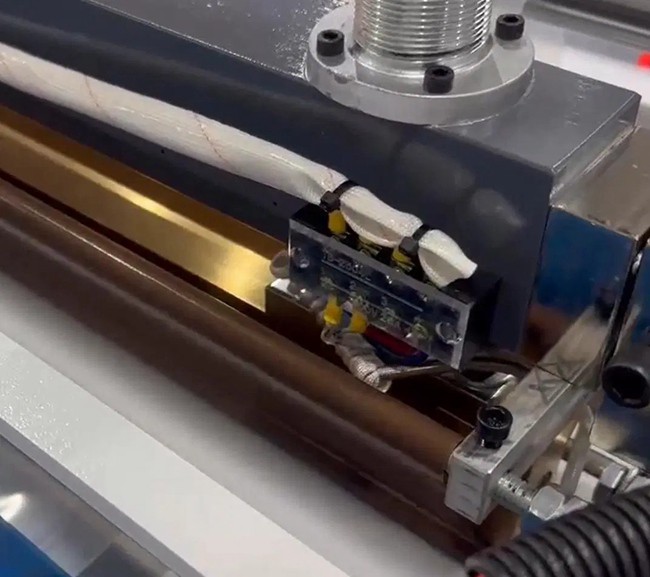

The storage device is responsible for storing and quantitatively supplying raw materials. Usually, the main raw material for producing garbage bags is polyethylene (PE) particles, which are heated and melted by specific machines before entering the subsequent production process. The storage device ensures accurate supply of raw materials through photoelectric control, providing stable raw material supply for continuous production. The stepper device drives the raw materials into the processing area, while the frequency converter controls the operating speed of key components such as the heat sealing cutter. The frequency conversion device adopts advanced Delta M-series frequency converters, which have functions such as automatic torque compensation, slip compensation, and automatic voltage stabilization, effectively protecting the motor, avoiding the impact of starting current on the power grid, and achieving energy conservation and consumption reduction.

Recommended products