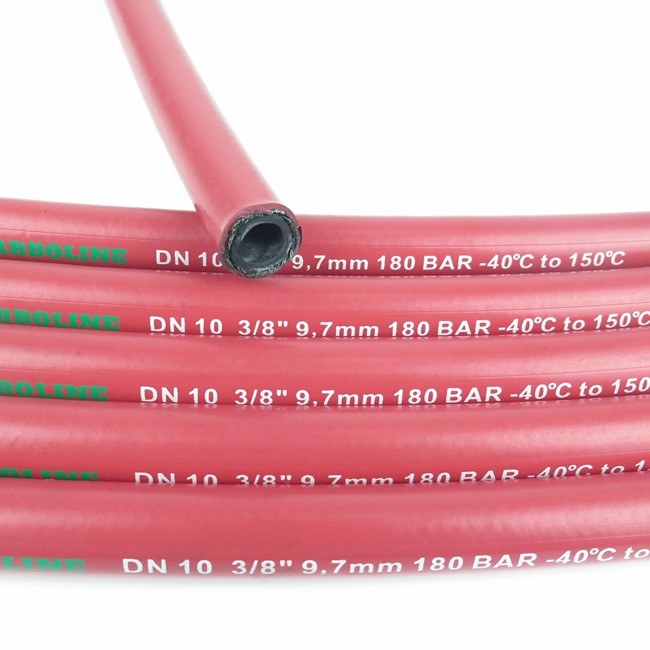

High Quality High Temperature Steel Wire Braided Reinforced Flexible Synthetic Rubber Steam Hose Pipe

Product description

Application of steam hoses

1. Food and beverage industry: used for cleaning and disinfecting equipment, as well as cooking and processing food.

2. Pharmaceutical industry: necessary for equipment disinfection and clean room environment maintenance.

3. Chemical industry: used for transporting steam, process heating, and reaction control.

4. Automotive industry: used for cleaning and painting processes, as well as maintenance of production equipment.

5. Heating system: used for distributing heating steam in large buildings and industrial facilities

Main Features of Steam Hose

Temperature Resistance: Withstands temperatures up to 450°F (232°C) or higher, depending on the specific design and material.

Pressure ratings: Available in a variety of pressure ratings to meet different industrial requirements, from low-pressure applications to those requiring high-pressure steam.

Flexibility: Flexible design for easy installation and mobility.

Durability: Manufactured from materials that are resistant to steam, chemicals and weather conditions to ensure long service life.

Steam hose is generally composed of three parts: the inner rubber layer, the intermediate layer and the outer rubber layer. The inner rubber layer is made of synthetic rubber with excellent heat resistance, such as EPDM (EPDM), which enables the transport medium to withstand pressure and protects the intermediate layer from erosion. The intermediate layer is usually braided wire or braided steel wire, used to strengthen the pressure range of the hose, improve strength and wear resistance. The outer layer, also made of synthetic rubber with excellent heat resistance, protects the inner and intermediate layers from external damage and provides additional protection.

Steam hose, also known as steam hose, is a type of hose that is mainly used in industrial production. Steam hose is a type of hose that is widely used in industrial production and is characterized by heat resistance, corrosion resistance, flexibility, pressure resistance and durability. Its unique structure and composition allow it to play an important role in a wide range of industrial environments. The manufacturing process for steam hose includes critical steps such as evaluating temperature ranges, chemical compatibility and pressure requirements. The manufacturing process involves ensuring that the hose material is heat and steam resistant and will not react with the material being transported. In addition, thoroughly emptying the steam hose after each use is an important practice to prevent damage such as bursting.

Recommended products