High-Accuracy Heat Exchanger Evaporator Blower Air Dryer Filter Steam Heat Exchanger

Product description

advantage:

High heat transfer coefficient and high heat transfer efficiency.

Compact structure, large heat exchange area, and small footprint.

High flexibility, the heat exchanger area and number of heat exchange sections can be adjusted according to needs.

Less consumables, easy maintenance and cleaning.

Disadvantages:

The sealing perimeter is long and there is a high chance of leakage.

Due to the limitations of the sealing material, the operating pressure and temperature cannot be too high.

Due to the small spacing between the plates, the flow rate should not be too high and the viscosity of the medium should be low during operation, while there should be no solid particles, otherwise it is easy to block the channels between the plates.

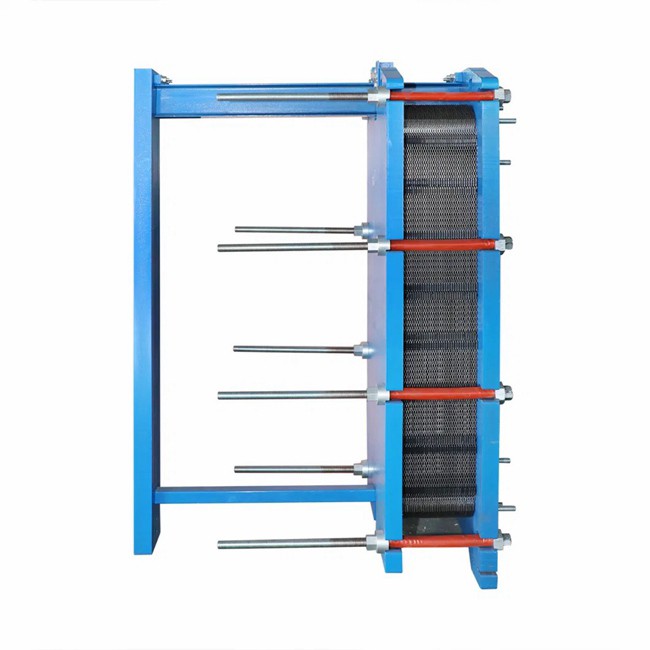

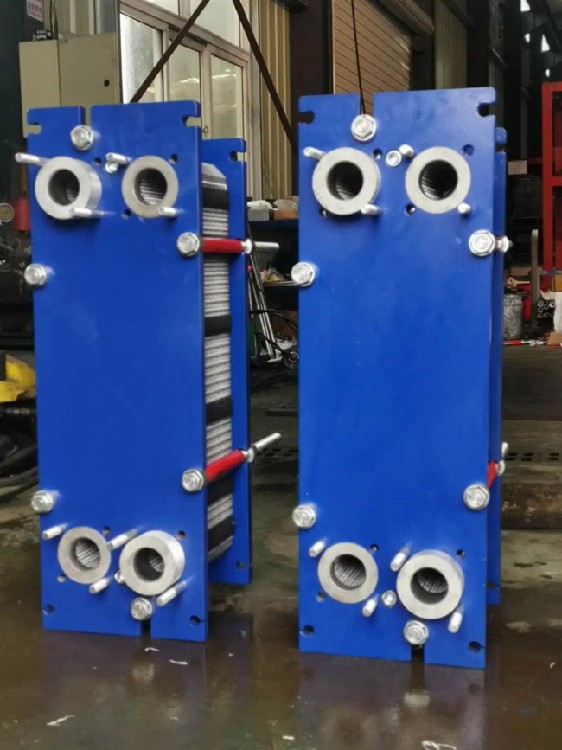

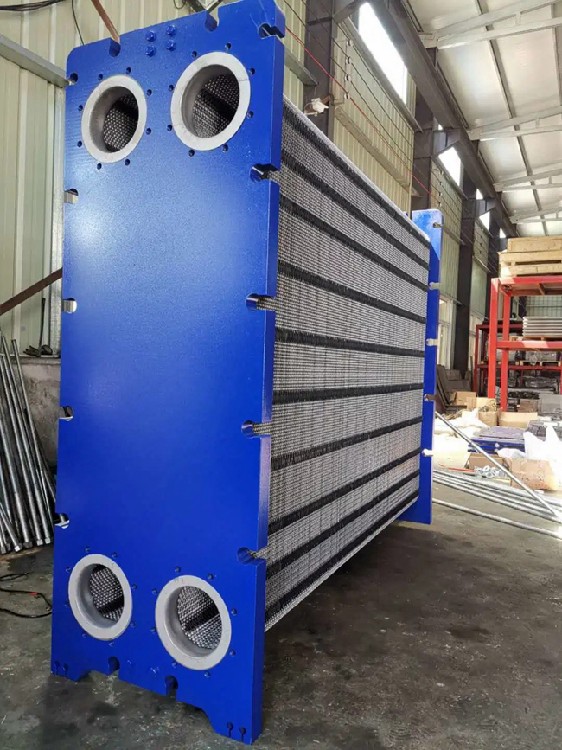

Plate heat exchanger is an efficient, compact, and flexible heat exchange device that has been widely used in multiple fields. However, it is also necessary to pay attention to its drawbacks and take corresponding measures to prevent it during use. There are two main types of plate heat exchangers: frame type (detachable) and brazed type. There are three types of plate forms: herringbone corrugated plate, horizontal flat corrugated plate, and nodular plate. These different types of plate heat exchangers have their own characteristics and are suitable for different working conditions and media.

Plate heat exchangers have a compact and lightweight structure, occupying a small area, only about one-third of that of tube heat exchangers. Plate heat exchangers can adjust the heat exchange area by changing the number of plates, and different baffles can be inserted to change the processing of cold and heat flows and the number of heat exchange sections to meet different process requirements. The heat transfer plate of the plate heat exchanger is processed by stamping, with high standardization, low consumables, and easy maintenance and cleaning.

Air dryer heat exchangers are widely used in various fields, such as industrial manufacturing, food processing, pharmaceutical and chemical industries, textile printing and dyeing, etc. In these fields, air dryer heat exchangers play a crucial role in ensuring smooth production processes and stable product quality.

Recommended products