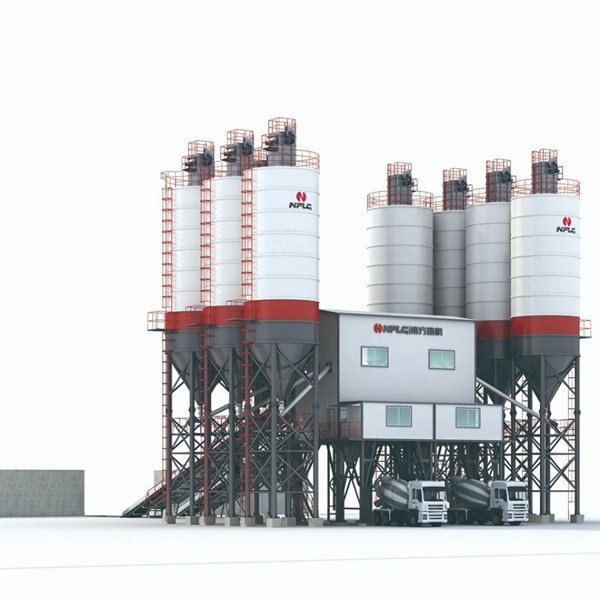

Customization Drawing Stationary Ready Mixed Concrete Batching Mixing Plant with Good Price

Product description

The development of concrete mixing plants is marked by significant technological progress. Nowadays, many factories are equipped with advanced computer systems that can control the entire mixing process, ensuring the accuracy and consistency of the produced concrete. These systems can also store various hybrid designs, allowing for quick and easy adjustments to meet the different needs of different building projects. Concrete mixing plants are also embracing sustainable development. Innovations such as using alternative fuels and raw materials, as well as recycling waste, are helping to reduce the carbon footprint of concrete production. In addition, developing energy-efficient factory designs and utilizing renewable energy are further steps towards a greener future.

The concrete mixing plant mainly consists of the following five systems and other ancillary facilities:

Mixing host: It is the core equipment of a concrete mixing plant, responsible for mixing and blending various raw materials.

Material weighing system: used for precise weighing of various raw materials to ensure the accuracy of concrete mix proportions.

Material conveying system: responsible for conveying various raw materials to the mixing host.

Material storage system: used for storing raw materials such as cement, sand, stone, etc.

Control system: Automatically control the entire mixing plant to ensure the smooth progress of the production process.

Recommended products