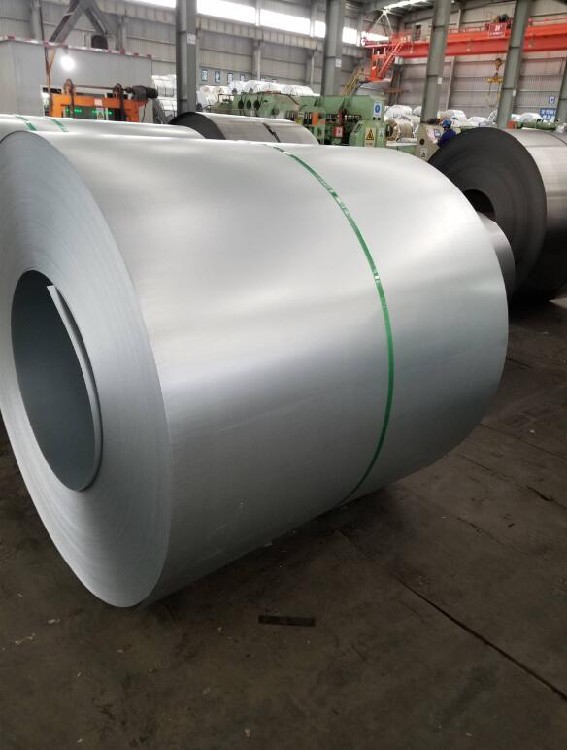

wholesale cold rolled galvanized steel coil

Product description

wholesale cold rolled galvanized steel coil

Cold-rolled galvanized steel coil is a steel sheet produced by a cold rolling process, and its surface is coated with a layer of zinc through a hot-dip or electroplating process to enhance corrosion resistance and durability. This steel coil not only has the advantages of cold-rolled steel, such as precise thickness, smooth and beautiful surface, excellent mechanical properties and processing performance, but also improves the corrosion resistance and service life of the product through the zinc coating process. Cold-rolled galvanized steel coil is widely used in many industries such as automobiles, construction, machinery manufacturing and instrumentation, and has become an important part of various industries due to its excellent strength, formability and corrosion resistance.

The production process of cold-rolled galvanized steel coil involves passing the steel sheet through rollers at room temperature to achieve the required thickness and smoothness, and then coating the surface with a layer of zinc through a hot-dip or electroplating process to form a protective barrier against rust and other environmental damage. This treatment not only provides long-lasting protection against rust, but also enhances the durability of the steel.

Advantages of Cold-rolled Galvanized Steel Coil

Excellent Strength and Durability: Compared with hot-rolled steel coil, cold-rolled galvanized steel coil has higher strength and durability, suitable for applications requiring high precision and structural integrity.

Excellent Formability: The cold rolling process improves the flatness and straightness of the steel, ensuring consistent quality. At the same time, cold-rolled galvanized steel coil has good formability and can be easily formed into different shapes for a variety of application scenarios.

Good Corrosion Resistance: The zinc coating acts as a shield to prevent the underlying steel from direct contact with moisture or oxygen, causing rust, and is particularly suitable for outdoor applications exposed to harsh weather conditions.

Low Maintenance Requirements: Galvanized steel coils have low maintenance requirements. By properly installing and regularly checking for any signs of damage or wear, they can provide long-lasting protection without the need for frequent touch-ups or repairs.

Thickness specification

Cold-rolled coil refers to steel coil produced by cold rolling process, and its thickness is generally implemented by the manufacturer in accordance with national standards. National standards stipulate that the thickness of cold-rolled coil is divided into the following grades:

1. Thin plate with thickness ≤ 0.35mm;

2. Medium and thin plate with thickness 0.35mm<≤0.60mm;

3. Thick plate with thickness 0.60mm<≤1.00mm;

4. Extra thick plate with thickness 1.00mm<≤3.00mm.

Thickness tolerance requirements

The standard has very strict requirements on the thickness tolerance of cold-rolled coils, and the specific requirements are as follows:

1. For thin plates and medium-thin plates, the thickness tolerance is ±0.01mm;

2. For thick plates and extra-thick plates, the thickness tolerance is ±0.5%;

3. In addition to the above provisions, the thickness tolerance shall not exceed the range specified in the standard.

Surface quality requirements for the thickness of cold-rolled coils

In addition to the thickness tolerance, requirements are also made for the surface quality of cold-rolled coils, which mainly include the following aspects:

1. The surface of the cold-rolled coil should be free of obvious scratches, pitting and other defects;

2. The surface of the cold-rolled coil should be free of obvious rust, rust and other pollution;

3. The surface of the cold-rolled coil should be flat and smooth.

Galvanized coils can be hot-rolled substrate galvanized or cold-rolled substrate galvanized.

The production process of galvanized coils involves hot-rolled steel strip or cold-rolled steel strip as the substrate, which is manufactured through a continuous hot-dip galvanizing process. Specifically:

Hot-rolled substrate galvanizing: Using hot-rolled steel strip as the substrate, it is produced through a continuous hot-dip galvanizing process. This type of steel plate has good paint adhesion and weldability, and is often used in construction, home appliances, automobiles, containers, transportation and household industries.

Cold-rolled substrate galvanizing: Using cold-rolled steel strip as the substrate, it is also produced through a continuous hot-dip galvanizing process. The surface quality, appearance and dimensional accuracy of cold-rolled steel plates are better than those of hot-rolled plates, but the cold rolling process will cause cold work hardening, resulting in increased hardness and decreased toughness. Therefore, cold-rolled substrate galvanizing is mainly used in occasions that require higher surface quality and accuracy requirements.

Recommended products