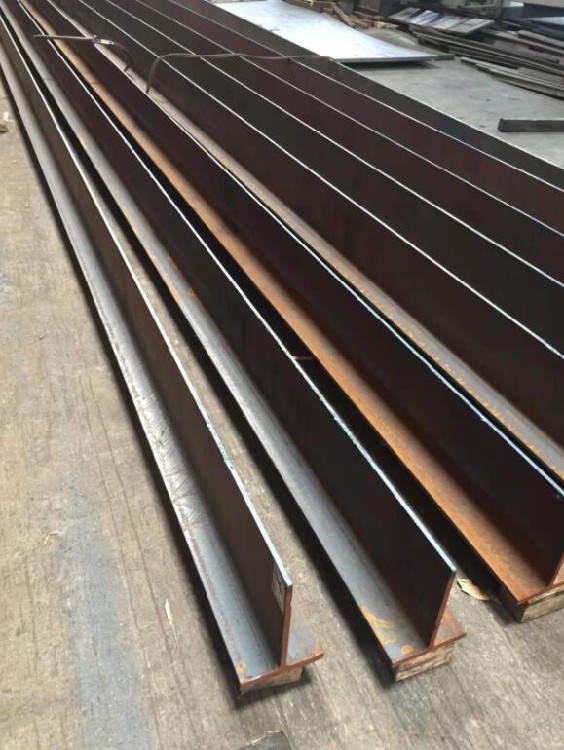

wholesale hot rolled galvanized steel

Product description

wholesale hot rolled galvanized steel

Hot-rolled galvanized sheet is directly galvanized after pickling with hot plate as the substrate. Compared with traditional galvanized sheet, it has obvious price advantages due to the lack of cold rolling process. It has good development prospects in the construction, automobile manufacturing, steel silo manufacturing, railway passenger car manufacturing, highway guardrail plate manufacturing and other industries.

With the development of hot rolling process technology, the quality of hot-rolled products has been continuously improved, and the thickness has gradually decreased. The production of hot-rolled galvanized sheet with hot-rolled thin plate as raw material has replaced the original traditional single sheet galvanizing, which not only broadens the scope of use of hot-rolled galvanized sheet, but also squeezes out the market share of hot-dip galvanized sheet with cold-rolled plate as the substrate. Internationally, hot-rolled galvanized sheet has been widely adopted.

With the advancement of hot rolling technology, especially the gradual maturity of thin slab continuous casting and rolling (CSP) technology, the thickness of hot-rolled steel strip is getting thinner and thinner. In recent years, many CSP production lines have been built in China, such as Zhuhai Steel, Handan Steel, Baotou Steel, Tangshan Steel, etc., and Ma Steel and Liangang Steel are currently under construction. The thinnest rolling specification can reach 0.8mm.

Manufacturing process

Hot-rolled steel plates are made by hot rolling process. The following are the manufacturing process steps of hot-rolled steel plates:

Raw material preparation: The continuous casting billet or ingot produced by the steel mill is sent to the rolling workshop for hot rolling.

Pretreatment: The raw material is heated to an appropriate temperature, usually between 1100°C and 1300°C, and some necessary surface treatment is performed, such as rust removal and oxide removal.

Rough rolling: The raw material is sent to a large rough rolling mill for rough rolling. The rough rolling mill usually consists of more than two rollers, and its main function is to flatten the raw material into a billet with a certain width and thickness.

Intermediate rolling: The billet after rough rolling is sent to a medium-sized rolling mill for intermediate rolling. The intermediate rolling mill consists of multiple rollers, which can usually further reduce the thickness of the billet and increase its width.

Finishing rolling: The billet after intermediate rolling is further sent to a small finishing mill for finishing rolling. The finishing mill usually consists of more rollers, which can further reduce the thickness of the billet and make its surface smoother.

Cooling: After finishing rolling, the steel plate will be sent to the cooling equipment for rapid cooling to prevent overheating and deformation of the steel plate.

Cutting and leveling: After cooling, the steel plate is cut into the required length and then sent to the leveling machine for surface treatment to make its surface smooth.

Packaging and storage: Finally, the hot-rolled steel plate will be packaged and stored in the warehouse for further processing or sale.

Thickness specification (national standard)

1. The thinnest galvanized sheet thickness is: 0.35.

2. The thickness specifications of galvanized sheets are: 0.35, 0.40, 0.45.

3. The sizes of galvanized sheets are: 710x1420, 750x1500, 750x1500, 750x1800, 800x800, 800x1200, 800x1600, 850x1700, 900x900, 900x1800 and 1000x2000.

Advantages of galvanized sheet

1. Strong corrosion resistance: Since the surface of the galvanized sheet is coated with zinc, it is not easy to be oxidized in the atmospheric environment, which can effectively prevent the corrosion and oxidation of the steel surface, thereby extending its service life.

2. High aesthetics: The surface of the galvanized sheet can be treated in a variety of ways, such as painting, plastic coating, etc., which can meet the needs of different colors and textures, thereby improving the aesthetics of the product.

3. High strength: The galvanized sheet has high strength, strong compression and bending resistance, and is suitable for applications in complex environments such as industrial buildings and civil buildings.

4. Easy to process: The processing performance of the galvanized sheet is good. It can be processed by cutting, bending, punching, stretching and other processing methods, which is convenient for the implementation of the manufacturing process.

5. Low cost: Compared with other metal materials with good corrosion resistance, the cost of galvanized sheet is low, and the performance is stable, which can meet the needs of mass production.

Disadvantages of galvanized sheet

1. Susceptible to chemical corrosion: Although galvanized sheet can effectively extend its service life, it is still susceptible to chemical corrosion in highly corrosive environments such as acid rain and marine environment.

2. Easy to fall off: Since the outer layer of the galvanized sheet is a zinc layer, the combination between the zinc layer and the steel plate is more susceptible to external factors and is easy to fall off or peel off.

3. High production cost: Although galvanized sheet is cheaper than other materials in terms of cost, its production difficulty and cost are high during the production and manufacturing process, and it requires a professional team to produce and manufacture.

4. Not resistant to high temperature: The characteristics of galvanized sheet determine that its high temperature resistance is poor, and it is not suitable for long-term use in high temperature environments.

Recommended products