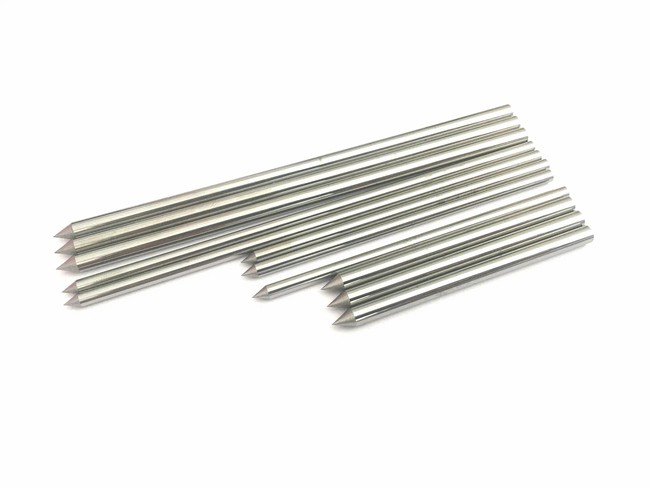

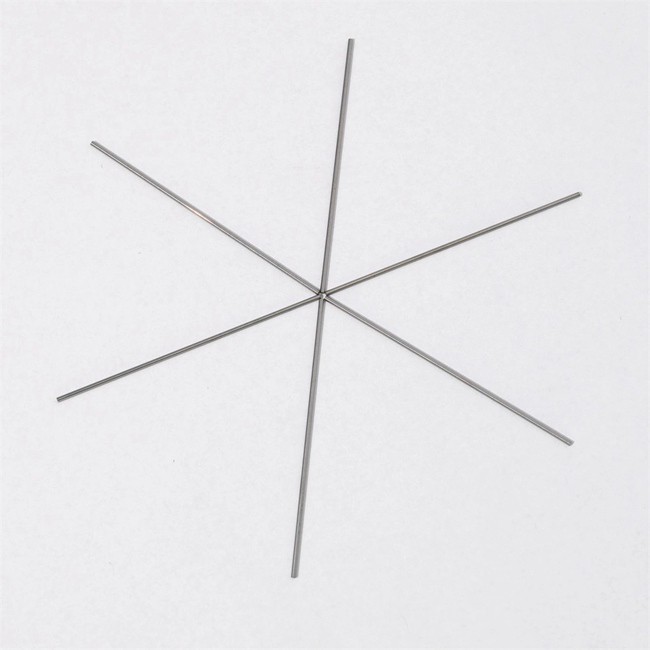

Selected Chinese Solid Cutting Drilling Milling Tools Tungsten Carbide Rod

Product description

Hard alloy rod is an alloy material with excellent performance and wide application fields. Its production process is complex but the technology is mature, which can meet various high demand industrial application needs. Hard alloy rods of different grades have different wear resistance, impact resistance, and applicable ranges, such as YG6, YG8, YG6X, YG10, etc. In addition, hard alloy rods can be processed and cut according to customer needs to meet the requirements of different application scenarios.

The excellent performance of hard alloy rods; Can be used for cutting difficult to machine materials such as heat-resistant steel, stainless steel, high manganese steel, and tool steel. Hard alloy rods are also widely used in industries such as wood processing, plastic processing, papermaking, packaging, printing, non-ferrous metal processing, as well as machinery, chemical, petroleum, metallurgy, electronics, and defense industries. The specifications and performance of hard alloy rods can be customized according to the specific needs of customers.

The production process of hard alloy rods mainly includes milling, formulation, wet grinding, mixing, crushing, drying, sieving, adding forming agents, re drying, sieving to obtain a mixture, granulation, pressing, forming, low-pressure sintering, external grinding and precision grinding (blank does not have this process), size inspection, packaging, warehousing and other steps. Among them, low-pressure sintering technology is one of the key technologies for producing high-quality hard alloy rods.

Hard alloy rods can maintain stable performance at high temperatures and have excellent corrosion resistance, making them suitable for long-term use in harsh environments. Hard alloy rods also have the characteristics of good red hardness, high elastic modulus, strong bending strength, and good chemical stability (acid, alkali, high temperature oxidation). Widely used in various cutting materials such as turning tools, milling cutters, planers, drills, boring cutters, etc., including cast iron, non-ferrous metals, plastics, synthetic fibers, graphite, glass, stone, and ordinary steel.

Recommended products