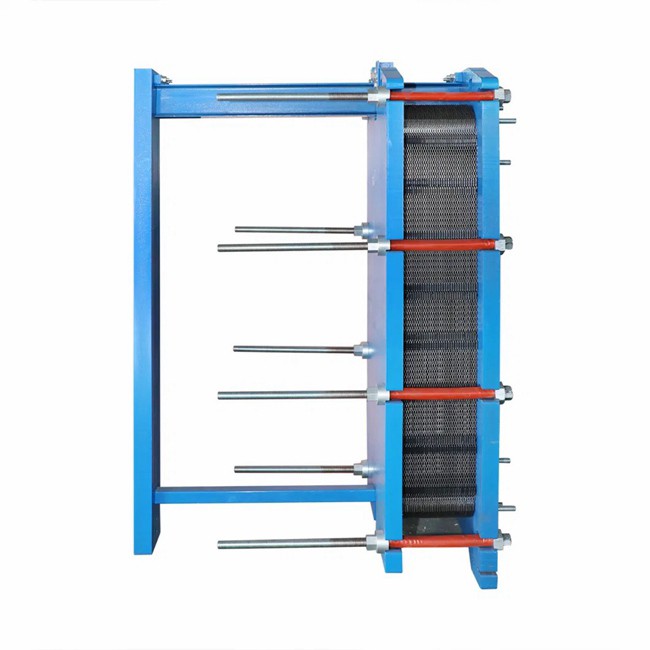

Customized Water Cool Chiller Refrigerated Air Dryer Stainless Plate Heat Exchanger

Product description

Application fields of plate heat exchangers

Refrigeration system: used for plate condenser and plate evaporator.

HVAC: Intermediate heat exchangers used in conjunction with boilers, high-rise building intermediate heat exchangers, etc.

Chemical industry: used for heating, cooling, evaporation concentration, condensation, etc. in processes such as soda ash industry, synthetic ammonia, and alcohol fermentation.

Solar energy utilization: Participate in the heat exchange process of heat transfer media such as ethylene glycol and antifreeze in solar collector panels.

Steel industry: cooling quenching oil, cooling electroplating solution, etc.

Food industry: sterilization and cooling of salt, dairy products, soy sauce, vinegar, heating and cooling of animal and vegetable oils, etc.

Textile industry: various waste liquid heat recovery, cooling of boiling phosphating fibers, etc.

Paper industry: Heating and cooling of cooling black water and bleaching saline alkali solution.

Central heating: Heating of waste heat areas in thermal power plants, heating of domestic water, etc.

Plate heat exchangers have a compact and lightweight structure, occupying a small area, only about one-third of that of tube heat exchangers. Plate heat exchangers can adjust the heat exchange area by changing the number of plates, and different baffles can be inserted to change the processing of cold and heat flows and the number of heat exchange sections to meet different process requirements. The heat transfer plate of the plate heat exchanger is processed by stamping, with high standardization, low consumables, and easy maintenance and cleaning.

Plate heat exchanger is an efficient heat exchange equipment, mainly composed of a series of metal sheets with specific corrugated shapes stacked together. These metal sheets form thin rectangular channels between them, and heat exchange is carried out through the plates, making it an ideal device for liquid-liquid and liquid vapor heat exchange. Plate heat exchangers have the characteristics of high heat transfer efficiency and low heat loss. Under the same pressure loss, its heat transfer coefficient is 3-5 times higher than that of a tube heat exchanger, and the heat recovery rate can reach over 90%.

Air dryer heat exchangers are widely used in various fields, such as industrial manufacturing, food processing, pharmaceutical and chemical industries, textile printing and dyeing, etc. In these fields, air dryer heat exchangers play a crucial role in ensuring smooth production processes and stable product quality.

The heat exchanger in an air dryer is an important component that mainly condenses the moisture in humid air into liquid water through heat exchange, and then removes the water through discharge or evaporation to achieve the purpose of drying the air. The following is a detailed analysis of the air dryer heat exchanger:

Recommended products