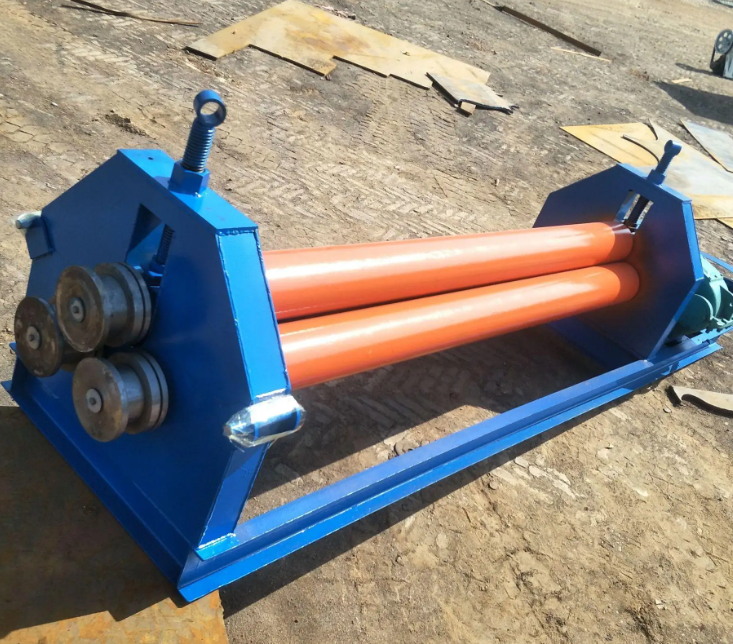

automatic plate rolling machine supplier

Product description

Our company has the right to import and export, and provides customers with cost-effective plate and profile bending and rolling equipment and technical services. The company's products include plate beveling machines, plate rolling machines, profile bending machines, CNC machine tool maintenance and repair services, etc.

The automatic feeding equipment of the plate rolling machine is mainly composed of a sheet trolley, an actuator, a sheet transmission mechanism and an auxiliary mechanism. The sheet trolley is used to place the sheet to be rolled. The main function of the actuator is to transport the sheet to be rolled on the sheet trolley to the feeding platform. The sheet handling operation is mainly used by rectangular coordinate manipulators and vacuum suction cup picking devices. In industrial automation systems, it is often necessary to pick up and transport workpieces, and vacuum suction cups are widely used as suction cup manipulators.

The transmission methods of rectangular coordinate manipulators mainly include mechanical transmission (gear rack transmission, synchronous belt transmission, ball screw transmission), linear motor transmission and pneumatic transmission. The sheet transmission mechanism is mainly used to transmit the sheet to be rolled, and common ones are roller shaft transmission and universal ball transmission. The main function of the auxiliary mechanism is to improve the sheet rolling accuracy. Common auxiliary mechanisms include sheet center alignment device, push device and displacement detection device.

Precautions for using the plate rolling machine

Preparation before operation: Before using the plate rolling machine, you must ensure that the equipment is in good working condition and check whether the hydraulic system, electrical system and mechanical components are normal.

Pretreatment of the plate: The plate should be pretreated before rolling, such as removing oil and rust on the surface, to ensure the rolling effect.

Safety during operation: Operators must wear protective equipment, such as safety helmets, protective glasses and protective gloves to avoid accidents during operation.

Maintenance of equipment: Regularly maintain the plate rolling machine, check the oil level and oil quality of the hydraulic oil, replace worn parts, and ensure the normal operation of the equipment.

Comply with operating procedures: Strictly operate in accordance with the operating procedures, avoid overloading the equipment, and ensure the service life and rolling quality of the equipment.

Recommended products