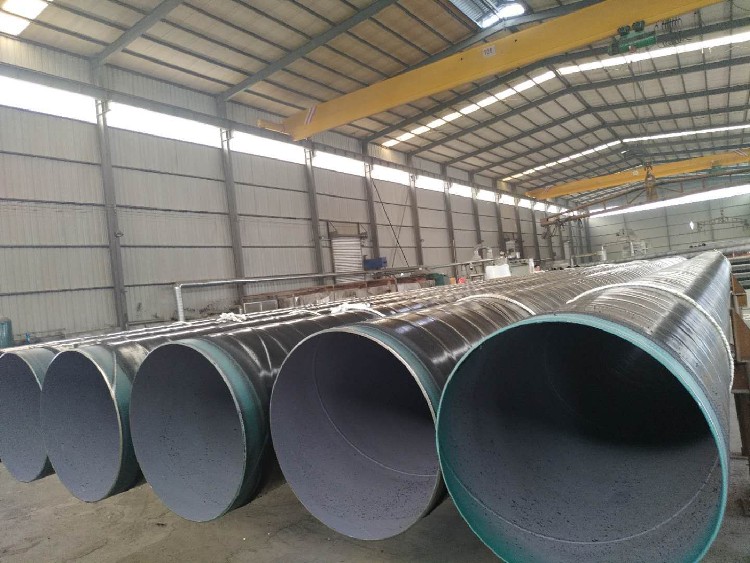

3PE (Three-Layer Polyethylene) Anti-Corrosion Steel Pipe

Product description

**Anti-Corrosion Steel Pipes** include PEEP anti-corrosion steel pipes, plastic-coated anti-corrosion steel pipes, water supply anti-corrosion steel pipes, TPEP anti-corrosion steel pipes, epoxy resin anti-corrosion steel pipes, plastic-coated composite pipes, large-diameter anti-corrosion steel pipes, steel sleeve steel, steam insulation pipes, 3PE anti-corrosion steel pipes, TPEP anti-corrosion steel pipes, FBE pipes, 3PP anti-corrosion steel pipes, insulation pipes, external 3PE steel pipes, external 3PE internal plastic-coated steel pipes, external 3PE internal epoxy-coated steel pipes, etc.

**Application Fields:**

- Gas pipeline engineering

**Connection Method:**

- Welded connection

**Product Brand:**

- Hebei Huaheng Pipeline Equipment Manufacturing Co., Ltd.

**Overview:**

3PE anti-corrosion steel pipe refers to a three-layer polyethylene coating (MAPEC) externally applied to steel pipes, which is a commonly used anti-corrosion pipeline in China. Other anti-corrosion methods include IPN8710, FBE epoxy powder, and epoxy coal tar.

**3PE Anti-Corrosion Steel Pipe 1**

**Product Description:**

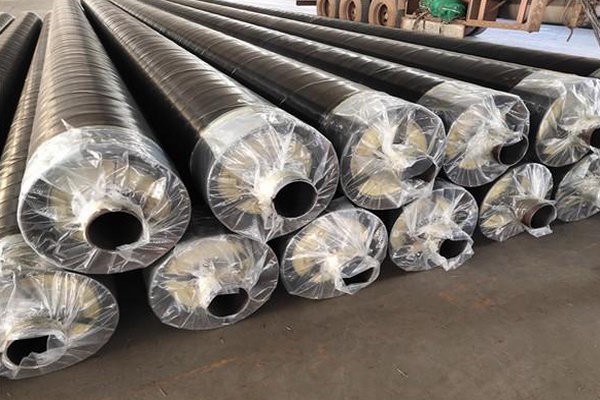

3PE anti-corrosion steel pipe refers to a three-layer polyethylene coating (MAPEC) externally applied to steel pipes, which is a commonly used anti-corrosion pipeline in China. Other anti-corrosion methods include IPN8710, FBE epoxy powder, and epoxy coal tar. Generally, it refers to the external wall anti-corrosion of steel pipes. The base material of 3PE anti-corrosion steel pipes includes seamless steel pipes, spiral steel pipes, and straight seam steel pipes. The three-layer polyethylene (3PE) anti-corrosion coating is widely used in the petroleum pipeline industry due to its excellent anti-corrosion properties, water vapor permeability resistance, and mechanical properties. The anti-corrosion layer of 3PE anti-corrosion steel pipes is crucial for the lifespan of buried pipelines. Pipelines made of the same material can remain uncorroded for decades when buried, while others may leak within a few years, depending on the external anti-corrosion layer used.

**Anti-Corrosion Structure:**

**External Wall Anti-Corrosion Form of Steel Pipes:**

3PE anti-corrosion generally consists of three layers:

1. First layer: Epoxy powder (FBE > 100um)

2. Second layer: Adhesive (AD) 170~250um

3. Third layer: Polyethylene (PE) 1.8~3.7mm

In practice, these three materials are blended into one, processed to form a strong bond with the steel pipe, creating an excellent anti-corrosion layer. The processing methods generally include winding and round mold coating.

The 3PE anti-corrosion steel pipe coating (three-layer polyethylene anti-corrosion coating) combines the European 2PE anti-corrosion layer with the epoxy powder anti-corrosion steel pipe coating (FBE) widely used in North America, resulting in a new type of anti-corrosion steel pipe coating. It has been recognized and used worldwide for over a decade.

The 3PE anti-corrosion steel pipe coating consists of an epoxy powder anti-corrosion coating in contact with the steel pipe surface, a copolymer adhesive with branched functional groups as the middle layer, and a high-density polyethylene anti-corrosion coating as the outer layer.

The 3PE anti-corrosion coating combines the high anti-permeability and mechanical properties of epoxy resin and polyethylene materials. It is globally recognized as the most effective and high-performance pipeline anti-corrosion coating, widely used in numerous projects.

**Domestic Standard:**

GB/T23257-2017

**Applications:**

3PE anti-corrosion steel pipes are widely used in long-distance oil and gas transmission pipelines, water transmission pipelines, sewage treatment pipelines, and external anti-corrosion of steel sleeve steam transmission pipelines.

**Process:**

The main process for making 3PE anti-corrosion steel pipes includes: external wall shot blasting, medium-frequency electric heating/natural gas furnace heating, epoxy powder spraying, adhesive extrusion winding, polyethylene extrusion winding, water cooling, pipe end anti-corrosion layer grinding, inspection, marking, and storage. The minimum processing diameter is Φ89mm, and the maximum is Φ3020mm.

**Advantages:**

Ordinary steel pipes can suffer severe corrosion in harsh environments, reducing their service life. Anti-corrosion insulation steel pipes have a longer lifespan, typically 30-50 years, and correct installation and use can reduce network maintenance costs.

3PE anti-corrosion steel pipes offer excellent performance, significant resource savings over long-term operation, reduced energy costs, strong waterproof and corrosion resistance, and do not require additional pipe trenches, allowing direct burial underground or in water. They are easy and quick to install, with low overall costs, and exhibit good corrosion and impact resistance at low temperatures, making them suitable for direct burial in frozen soil under certain conditions.

Recommended products