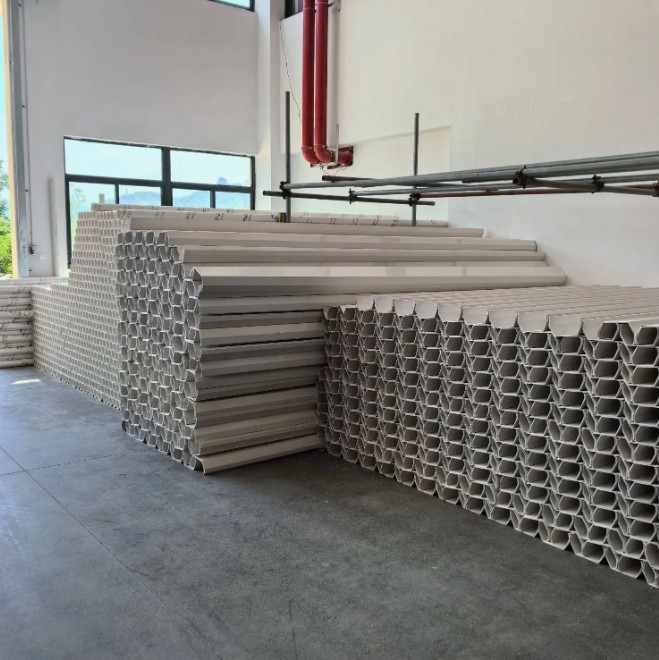

Flexible cable wire protection hose cable covering PVC Cable Conduits

Product description

PVC (Polyvinyl Chloride) cable conduits are essential components in electrical and telecommunications systems, designed to protect and route wiring in residential, commercial, and industrial environments. These rigid or flexible tubes safeguard cables from physical damage, moisture, chemicals, and environmental stressors, ensuring safe and reliable power and data transmission. This article provides an overview of PVC cable conduits, highlighting their key features and advantages.

Product Overview

PVC cable conduits are hollow tubes manufactured from high-quality polyvinyl chloride, a durable and non-conductive thermoplastic. Available in various sizes, thicknesses, and configurations (e.g., rigid, flexible, or corrugated), they are engineered to meet international safety standards such as UL, IEC, and RoHS. These conduits are widely used to encase electrical wires, fiber optics, and communication cables in both indoor and outdoor installations.

Key Features of PVC Cable Conduits

Superior Electrical Insulation

PVC is inherently non-conductive, making it an ideal material for preventing electrical hazards. It isolates cables from external electrical interference and reduces the risk of short circuits.

Corrosion and Chemical Resistance

Unlike metal conduits, PVC resists rust, acids, alkalis, and solvents, ensuring long-term performance in harsh environments like industrial plants or coastal areas.

Lightweight and Easy to Install

PVC conduits are significantly lighter than metal alternatives (e.g., steel or aluminum), simplifying handling, cutting, and installation. They can be easily bent (for flexible types) or joined using solvent cement, reducing labor time and costs.

Durability and Impact Resistance

Reinforced PVC conduits withstand physical stress, vibrations, and UV exposure (when UV-stabilized), maintaining structural integrity in demanding conditions.

Waterproof and Moisture-Resistant

Sealed PVC conduits prevent water ingress, protecting cables from humidity, rain, and underground moisture—critical for outdoor or underground applications.

Flame Retardancy

Many PVC conduits are formulated with flame-retardant additives, meeting fire safety standards (e.g., UL 94) to slow flame spread and minimize smoke emission.

Smooth Interior Surface

The smooth inner walls reduce friction during cable installation, preventing damage to insulation and simplifying future maintenance or upgrades.

Cost-Effective Solution

PVC conduits offer a budget-friendly alternative to metal options with lower material and installation expenses while delivering comparable performance.

Versatility

Available in multiple colors (e.g., white, gray, orange for easy identification) and types (rigid, flexible, or split conduits), PVC accommodates diverse wiring needs from tight corners to straight runs.

Eco-Friendly Options

Recyclable PVC conduits and those made with recycled materials align with sustainable construction practices, reducing environmental impact.

Applications of PVC Cable Conduits

Residential Wiring: Protect electrical circuits in walls, ceilings, and underground installations.

Commercial Buildings: Organize and shield cables in offices, hospitals, and retail spaces.

Industrial Facilities: Safeguard machinery wiring in factories, plants, and warehouses exposed to chemicals or vibrations.

Telecommunications: Route fiber optic and data cables in IT infrastructure.

Outdoor Installations: UV-resistant conduits are used for street lighting, solar panel systems, and underground utility lines.

Renewable Energy: Ideal for solar and wind power installations requiring durable and weatherproof cable management.

Advantages Over Traditional Materials

No Rust: Outperform metal conduits in humid or corrosive environments.

Ease of Modification: Can be cut, bent, or adapted on-site without specialized tools.

Lower Maintenance: Resist degradation, eliminating the need for frequent replacements.

Safety: Non-conductive properties enhance protection against electrical faults.

Why you should choose us?

Established in 2017, Cangzhou Honghu Electrical Manufacturing Co. Ltd is a professional manufacturer of various sheet metal parts, stamping parts, precision CNC machined parts, and customized components. With many years of OEM work for our customers, we have gained rich and vast experience and gathered a group of skilled workers and experienced engineers. Products are exported to Japan, USA, Canada, Germany, Russia, India, Dubai and Peru, Mexico, South Africa and other countries.

Recommended products