Plastic Raw Material Machinery: Advanced Solutions for Efficient and Sustainable Production

Product description

Product Overview

Plastic Raw Material Machinery encompasses a comprehensive suite of industrial equipment engineered to optimize the processing, shaping, and recycling of plastic materials. Designed to meet the demands of diverse industries, these systems handle everything from polymer granule preparation and precision molding to eco-friendly material recovery, ensuring high output, consistency, and compliance with global sustainability standards.

Core Product Range

1. Extrusion Systems: High-performance single-crew and twin-screw extruders for melting, homogenizing, and forming plastics into pellets, films, pipes, or custom profiles.

2. Injection Molding Units: Precision machines are capable of producing complex and high-tolerance components with rapid cycle times and minimal material waste.

3. Blow Molding Equipment: Versatile solutions for manufacturing hollow plastic products, including bottles, tanks, and automotive parts.

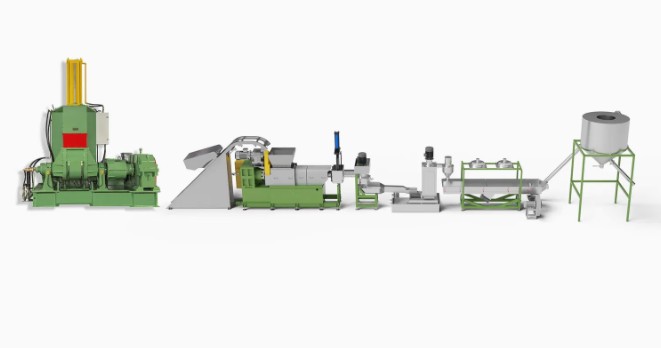

4. Compounding Lines: Advanced mixing systems for blending base polymers with additives, fillers, or recycled materials to create specialized compounds.

5. Recycling Systems: Turnkey solutions for sorting, washing, shredding, and reprocessing post-consumer or industrial plastic waste into reusable raw materials.

Industry Applications

Ideal for sectors such as packaging, automotive, electronics, medical devices, and construction, this machinery supports the creation of lightweight, durable, and recyclable plastic products tailored to modern market needs.

Key Advantages

1. Unparalleled Efficiency

- Intelligent automation and energy-saving technologies reduce power consumption by up to 40%, lowering operational costs and carbon footprints.

- High-speed production cycles and automated material handling maximize throughput for large-scale manufacturing.

2. Precision and Consistency

- State-of-the-art servo drives, PLC controls, and real-time monitoring systems ensure repeatable accuracy in product dimensions and material properties.

- Adjustable parameters (temperature, pressure, screw speed) accommodate diverse plastics, including PP, PE, PET, PVC, and biodegradable resins.

3. Eco-Conscious Design

- Integrated recycling systems feature advanced purification and decontamination processes, transforming waste into high-purity feedstock for circular production.

- Compliance with international environmental regulations (e.g., EU RoHS, REACH) guarantees safe and sustainable operations.

4. Robust Construction and Longevity

- Heavy-duty frames, corrosion-resistant components, and wear-resistant surfaces ensure durability even in harsh industrial environments.

- Modular designs simplify maintenance, upgrades, and part replacements, minimizing downtime.

5. Adaptability and Scalability

- Flexible configurations support small-batch prototyping or mass production with seamless integration into existing workflows.

- Compatible with both virgin and recycled materials, future-proofing operations against evolving market trends.

6. Smart Technology Integration

- IoT-enabled diagnostics and predictive maintenance tools provide real-time insights into machine health, preventing unplanned outages.

- User-friendly interfaces with touchscreen controls and remote access capabilities streamline operator training and process management.

7. Global Compliance and Support

- Machinery meets ISO, CE, and UL certifications for safety and performance.

- Worldwide technical support networks offer rapid assistance, spare parts delivery, and on-site service to ensure uninterrupted production.

Why Invest in Plastic Raw Material Machinery?

In a competitive and environmentally conscious market, advanced plastic processing equipment is critical to achieving cost efficiency, product innovation, and sustainability goals. These systems empower manufacturers to:

1. Reduce Waste: Closed-loop recycling minimizes material loss and landfill dependency.

2. Enhance Quality: Precision engineering ensures defect-free outputs for demanding applications.

3. Cut Costs: Energy-efficient operations and low maintenance requirements boost profitability.

4. Stay Compliant: Adherence to global standards future-proofs businesses against regulatory changes.

Drive Your Production Forward

Upgrade your plastic manufacturing capabilities with machinery that combines cutting-edge technology, environmental responsibility, and operational excellence. Whether producing consumer goods, industrial components, or recycled materials, these systems deliver the performance and flexibility needed to thrive in a dynamic industry.

Why Choose Us?

Jiangsu Aceretech Machinery Co., Ltd. is a dynamic and innovative machinery manufacturing enterprise based in Jiangsu, China, specializing in the design, production, and distribution of high-performance processing equipment for industries such as food, pharmaceuticals, chemicals, and environmental protection. With a commitment to technological excellence and customer-centric solutions, the company integrates advanced automation, precision engineering, and sustainable practices to deliver reliable machinery tailored to global client needs. Backed by a skilled R&D team, stringent quality control systems, and ISO-certified processes, Aceretech ensures optimal efficiency, durability, and compliance with international standards while offering comprehensive after-sales support to foster long-term partnerships worldwide.

Recommended products