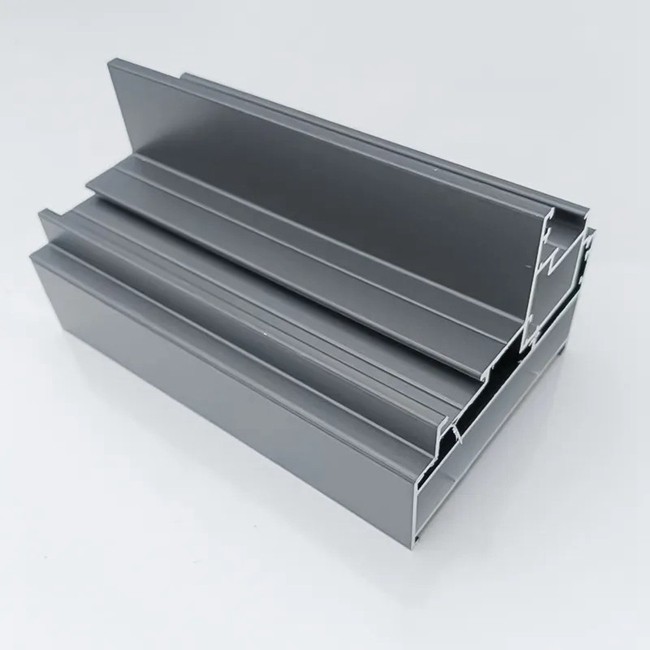

Factory Direct Sale is used for wood-grain aluminium profiles of doors and Windows

Product description

In the world of construction, manufacturing, and design, aluminum profiles have emerged as a cornerstone material, offering unparalleled versatility, durability, and sustainability. These extruded aluminum shapes, also known as aluminum extrusions, are engineered to meet the demands of diverse industries from architectural marvels to cutting-edge industrial machinery. This article explores the fundamentals of aluminum profiles, their manufacturing process, key advantages, and wide-ranging applications.

What Are Aluminum Profiles?

Aluminum profiles are custom-shaped components created by forcing heated aluminum alloy through a die in a process called extrusion. The resulting products are long and uniform cross-sectional shapes that can be tailored to specific design requirements. Common profiles include channels, angles, T-sections, tubes, and complex geometries for specialized uses. These profiles are often further processed through cutting, machining, or surface treatments to enhance functionality and aesthetics.

The Extrusion Process: From Raw Material to Precision Shape

The production of aluminum profiles involves several critical steps:

Alloy Selection: Aluminum alloys (e.g., 6061, 6063) are chosen based on desired properties such as strength, corrosion resistance, or thermal conductivity.

Heating: Billets (cylindrical aluminum blocks) are heated to 400–500°C to make the metal pliable.

Extrusion: The softened aluminum is forced through a precision die using hydraulic or mechanical pressure, shaping it into the desired profile.

Cooling & Stretching: The extruded profile is rapidly cooled and stretched to ensure dimensional stability.

Finishing: Processes like anodizing, powder coating, or polishing are applied to improve durability and appearance.

Why Choose Aluminum Profiles?

Lightweight Strength: Aluminum boasts an exceptional strength-to-weight ratio, making it ideal for applications where reducing weight is critical (e.g., aerospace, automotive).

Corrosion Resistance: Naturally forming an oxide layer protects against rust even in harsh environments.

Design Flexibility: Complex geometries can be extruded in a single step, enabling innovative engineering solutions.

Thermal & Electrical Conductivity: Ideal for heat sinks, electrical enclosures, and renewable energy systems.

Sustainability: Aluminum is 100% recyclable without quality loss, aligning with circular economy goals.

Cost Efficiency: Extrusion allows mass production of intricate shapes with minimal post-processing.

Applications Across Industries

Architecture & Construction: Window frames, curtain walls, structural supports, and solar panel mounting systems.

Transportation: Lightweight vehicle frames, railcar components, and marine structures.

Industrial Machinery: Conveyor systems, robotic arms, and modular workstations.

Consumer Goods: Furniture, electronics casings, and DIY modular systems.

Energy: Wind turbine components, heat exchangers, and photovoltaic frameworks.

Innovations and Future Trends

Advancements in aluminum extrusion technology continue to push boundaries:

Hybrid Profiles: Integration of composite materials or thermal breaks for enhanced performance.

Smart Extrusions: Profiles with embedded sensors or wiring channels for IoT-enabled systems.

Sustainable Manufacturing: Increased use of recycled aluminum and energy-efficient extrusion processes.

About Us

FOSHAN XINWEI ALUMINUM Co., Ltd. is a professional manufacturing enterprise that mainly produces industrial and household aluminum profiles and products. It has a team of experienced technical staff and efficient managerial staff. It is also equipped with 6 advanced aluminum extrusion lines and quality control equipment to ensure first-class products to be produced.

The whole production process includes: Aluminum ingot casting, extrusion mold design and making, extruding, aging treatment, surface treatment (including sandblasting, anodizing, powder coating and spraying. What′s more, we have already got the ISO9001 Quality Management System and ISO14001 Environmental Management System certifications.

We produce more than 2500 items of construction and industrial profiles, windows and doors, and household products. The manufacturing capability of company reaches 10000 tons a year. 90% of our products are mainly sold to overseas markets such as Europe, North America, Africa, Southeast Asia, HK, and Macao. At the same time, our company is nominated as approved supplier of several multinational corporations.

We are ready to make all kinds of aluminum alloy profiles and products according to customers′ samples or drawings to meet the demand of markets.

Recommended products